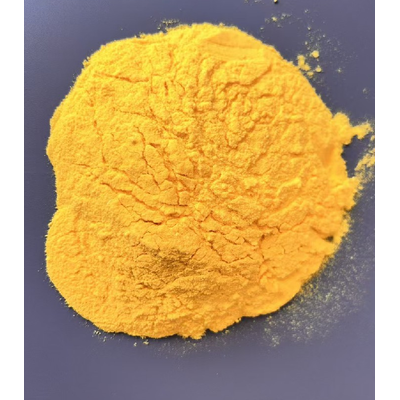

Unikem - Poly Aluminum Chloride (PAC)

Poly aluminum chlorides are a class of aluminum-based, inorganic polymeric chemicals containing aluminum, chloride, and hydroxide with a range of aluminum to chloride ratios. Polyaluminum chlorides are primarily used for coagulation in water and wastewater treatment and may be custom formulated as part of a trademarked blend of mixed aluminum polymers for this purpose. Water treatment applications are among the most common uses of polyaluminum chlorides in the world.

Poly aluminum chlorides are a class of aluminum-based, inorganic polymeric chemicals containing aluminum, chloride, and hydroxide with a range of aluminum to chloride ratios. Polyaluminum chlorides are primarily used for coagulation in water and wastewater treatment and may be custom formulated as part of a trademarked blend of mixed aluminum polymers for this purpose. Water treatment applications are among the most common uses of polyaluminum chlorides in the U.S.

Use in Water Treatment

Poly aluminum chlorides are utilized directly in primary coagulation in drinking water and municipal wastewater treatment. Polyaluminum chlorides are also used in sludge dewatering applications (AWWA, 2010).

Use as a Precursor to Other Water Treatment Chemicals

Poly aluminum chlorides are not used to manufacture other water treatment chemicals.

Other Applications

Polyaluminum chlorides have a wide range of applications, including production of paper and textiles, cleaning products, personal care products such as antiperspirants and deodorants, adhesives and binding agents, and as one of many chemicals in drilling fluid used for hydraulic fracturing (EPA, 2020; Gulbrandsen Technologies, n.d.; Kemira, n.d.).

Primary Industrial Consumers

The primary domestic uses of polyaluminum chlorides are water and wastewater treatment including industrial wastewater treatment, paper and textile production, antiperspirant and deodorant production, and chemical manufacturing (EPA, 2020; Gulbrandsen Technologies, n.d.; Kemira, n.d.).

Manufacturing & Storage

Manufacturing Process

A variety of processes exist for producing polyaluminum chlorides. Manufacturing technique may depend on the basicity (i.e., the hydroxide to aluminum ratio) and strength (i.e., percent aluminum oxide) required in the final formulation. Inputs include a source of aluminum and hydrochloric acid. Generally, low basicity formulas are produced through a reaction of aluminum hydroxide with hydrochloric acid or aluminum chloride. For water treatment applications where a higher-basicity formula is desired, additional steps are required. Additional steps to produce high basicity polyaluminum chloride are characterized by use of one of two primary, conventional methods. The first method relies on the reaction of the low-basicity polyaluminum chloride or aluminum chloride with a base, such as sodium hydroxide. The second method utilizes the reaction of low-basicity polyaluminum chloride or aluminum chloride or hydrochloric acid with aluminum metal. Additional reactions between hydrochloric acid or aluminum chloride or low-basicity polyaluminum chloride with aluminum metal can produce an ultra-high-basicity polyaluminum chloride. The ultra-high basicity polyaluminum chloride is known as aluminum chlorohydrate (AWWA, 2010; Shen and Dempsey, 1998).

Storage and Shelf Life

Polyaluminum chlorides should be stored in a tightly closed container and kept indoors or above freezing. When stored properly, polyaluminum chlorides can have a shelf life of approximately 12 months, depending on storage conditions and mixture components (GEO Specialty Chemicals, 2015; Kemira, 2014).