- Home

- Companies

- Brentwood Industries, Inc.

- Products

- Polychem® - Non-Metallic Telescoping ...

Polychem® - Non-Metallic Telescoping Head Shaft

The Polychem non-metallic telescoping head shaft was invented and installed as part of the first 100% non-metallic system in 1984. At that time, the industry was just beginning to test plastic as a lighter, corrosion-resistant alternative to steel. Today, Polychem non-metallic head shafts have become the water treatment industry’s gold standard.

The head shaft’s unique assembly does not require crane installation and is virtually maintenance free. Two fiberglass end tubes with internal bearings and keyways overlap a center tube and are joined together with torque interlocks and set collars to form one robust, easy-to-lift shaft. Since its introduction, the Polychem telescoping head shaft design has been utilized in over 12,000 systems worldwide.

- Design allows for increased field adjustability

- Easily slides over pre-installed, wall-mounted spindles

- Composed of high-strength, biaxially wound FRP

- Available in mono- & jumbo-tube designs

- Metallic shafting available

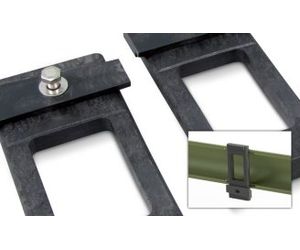

Wall-mounted spindles support the tube assemblies as they rotate on internal tubular bearings and are equipped with jacking bolts for ease of alignment.

Collars secure telescoping tubes and are fastened with a 316 SS band clamp.

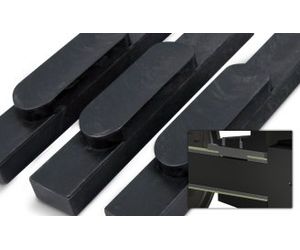

Molded Nylon 6-6 keys connect the head shaft sprockets to the tubular shaft assembly, allowing the sprockets to transmit torque to the system.

The torque interlock system connects the three overlapping tubes to form one shaft and is secured with a set of collars and keys.

Water-lubricated UHMW-PE tubular bearings spin on the spindle and are keyed to the outer end tubes to support the shaft.