- Home

- Companies

- Midwest Industrial Supply, Inc.

- Products

- Midwest - Polymer-Stabilized Full-Depth ...

Midwest - Polymer-Stabilized Full-Depth Reclamation (FDR)

Midwest’s smarter, more sustainable way to reclaim and stabilize failed roads. Midwest Reclaims Existing Pavement With Engineered Liquid Binders. Turn crumbling asphalt and base layers into strong, stabilized roads. It’s time to rethink how you rebuild failed roads. Midwest polymer-based innovation stabilizes reclaimed roads to create a stronger, longer-lasting foundation. Midwest helps municipalities, DOTs, and contractors complete Full-Depth Reclamation (FDR) projects using engineered liquid binders that deliver the performance of cement without the harmful environmental impact.

The Midwest FDR process pulverizes existing asphalt and base layers in place, creating a stabilized foundation ready for paving or chip seal. There is no need to haul out old materials or truck in new aggregate. This saves time, money, and emissions.

Upgrade to a stronger road base in only five easy steps.

Midwest is built on the idea that there is always a better way. Our polymer-stabilized FDR is a versatile solution for road rehabilitation — from structurally failed low-volume municipal streets to higher-capacity paved roads. While it excels in utility-constrained or shallow-depth applications, it also delivers reliable performance for state DOTs and contractors seeking a low-impact alternative to cement-based stabilization.

Reuse what’s already there to save time and budget

Stabilizes in place, even above utilities or in tight vertical profiles

Controls shrinkage and reflective cracking in overlays

Traffic can often resume the same day

Dust-free liquid binder blends easily using traditional roadwork equipment

Proven safe in sensitive areas with no leaching and no toxic runoff

Flexible base improves durability and lowers long-term costs

Stabilized roads require less frequent repair and resurfacing

Midwest’s polymer-stabilized FDR is a smarter way to rebuild failing roads. By pulverizing the existing asphalt and base, then treating it in place, agencies can eliminate structural problems and accelerate project timelines without hauling away existing material.

This also preserves the existing road profile, which is essential in areas with buried utilities or grade constraints. While unstabilized FDR offers some benefits, treating the reclaimed base with our engineered polymers significantly improves strength, load-bearing capacity, and moisture resistance.

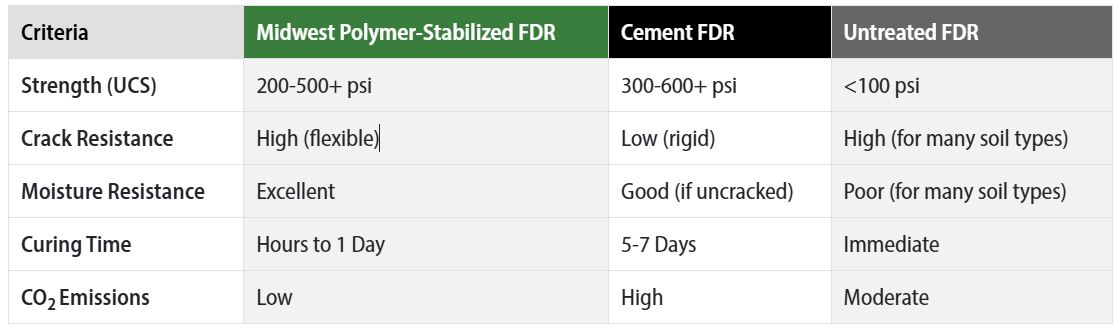

Midwest surpasses traditional methods.Cement and lime introduce delays, brittleness, and environmental drawbacks. Midwest’s engineered stabilizers provide structural strength with the added benefits of flexibility, durability, and lower environmental impact.

Polymer-stabilized FDR is not only faster, greener, and more economical over time. The flexible base of Midwest’s solution resists both shrinkage and reflective cracking, extending surface life and reducing the need for ongoing repairs. Combine that with faster traffic return, often within 12 hours, and overall project impact on the public is reduced. For agencies focused on budgets, efficiency, and environmental performance, it’s a smarter long-term investment.

High strength and a low carbon footprint.Our solution delivers meaningful strength gains — often exceeding 200 psi UCS — providing a stable and durable base suitable for a wide range of road applications. While cement stabilization can produce higher compressive strength in some cases, Midwest’s polymer-stabilized FDR provides strong, flexible performance without the rigidity or environmental drawbacks of cement.

Midwest’s polymer-stabilized FDR delivers the strength needed for most low-volume and municipal roads, along with faster curing, crack resistance, and up to 80 percent lower lifecycle CO2 emissions. It offers a smarter, more sustainable way to rebuild roads while reducing environmental impacts and supporting a carbon-conscious infrastructure.

ACHIEVES DOT PERFORMANCE STANDARDS WITH UP TO 80 PERCENT LOWER CO2 EMISSIONS THAN CEMENT. NO COMPROMISE. JUST CLEANER PERFORMANCE.