- Home

- Companies

- Efficiency Scientific Instrument Co., ...

- Products

- ESI - Model Compass 4294 - Portable ...

ESI - Model Compass 4294 -Portable EDXRF Sulfur Analyzer

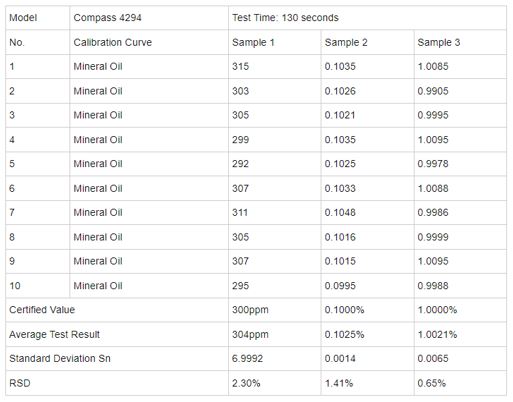

The Compass 4294 Energy-Dispersive X-Ray Fluorescence (EDXRF) systems was especially designed for on-board total sulfur content analysis in wide concentration range from ppm to percent levels. The portable compact design with low detection limits and high accuracy makes the Compass 4294 the ideal tool for sulfur testing at sea,offshore or on land. Conforms to the specifications of: ASTM D4294, D5059, D6481, ISO 20847, ISO 8754, IP 496, IP 336, JIS K 2541-1.

Simply the Best

For the determination of total sulfur in petroleum and petroleum products. These materials can include diesel fuel, jet fuel, kerosene, other distillate oil, naphtha, residual oil, lubricating base oil, hydraulic oil, crude oil, unleaded gasoline, gasohol, and similar petroleum products. Also, for the determination of the total lead content of a gasoline.

Conforms to the specifications of: ASTM D4294, D5059, D6481, ISO 20847, ISO 8754, IP 496, IP 336, JIS K 2541-1

Rapid elemental analysis of chlorine, lead, sulfur and metals in crude, oils, gasoline, fuels, lubricants and waste materials

Sulfur is an element commonly found in crude oil and petroleum products. Sulfur is considered an undesirable contaminant because, when burned, it generates sulfur oxides. Consequently, most finished petroleum products have a limit on how much sulfur they can contain, making sulfur removal an important part of the overall refinery process. Sulfur can also harm some of the catalysts used in refining process units so it must be removed from some intermediate streams before they can be fed to a conversion unit.

As a general rule, a crude oil grade with high sulfur content will have a lower value. This type of crude is often referred to as a sour crude.

Most of the sulfur in crude oil is removed during processing. Some of it is removed in conversion processes as hydrocarbon molecules that contain sulfur are cracked and form H2S. Sulfur is also removed directly by processing a hydrocarbon stream through hydrotreating, where the sulfur in the hydrocarbon is replaced with a hydrogen atom, and the released sulfur is combined with two free hydrogens to form H2S gas.

Meanwhile, sulfur control is widely applied, for example In India, all automotive diesel and gasoline was transitioned to Bharat IV with a 50 ppm maximum sulfur in April 2017.

Maximum permissible level of sulfur in fuel in Europe for 2003/17/EC (or EURO VI) directive requires a maximum amount of sulfur in fuel of 10 ppm.

Aviation Turbine Fuels specifications such as ASTM D1655 and D6615 require a maximum sulfur of 3000 ppm.

- Small, compact instrument design

- Little maintenance

- No need for water, compressed air or gases

- Low electrical consumption

- Improved system resolution

- Simultaneous elemental analysis

- Analysis of Sulfur content in bunker diesel fuels

- Analysis of hydrocarbon samples of heating oil, kerosene, jet A, vacuum gas oil (VGO), and crude oil

- Analysis of Cl, Mg and K in marine fuel

- Analysis of catalysts in the fuel- avoiding engine failure

- Detector: High Resolution SDD

- Excitation Source: 4 watts high efficiency micro tube, 50kv Max,200uA Max

- Working temperature: -20 to 50 °C

- Test environment: Air (4294) and vacuum (4294 Plus)

- Measuring time per sample: 130 seconds

- Sample Type: Liquid, powders and solids

- Factory Calibration

- Low sulfur: 10ppm- 100ppm

- High sulfur: 0.01%-5%

- Detection Limit of Sulfur

- 3.8ppm (Air)- Compass 4294

- 1.0ppm (Vacuum)- Compass 4294 Plus

- Instrument Dimension: 270mm*320mm*230mm(L*W*H)

- Sample Chamber Dimension: 170mm*110mm*17mm(L*W*H)

- Weight: 9.4 kg

- Operation touch Screen(1280*800): 8 inches Windows 10 based OS

- External Connection: USB Port, Blue-tooth, Wi-Fi, GPS

- Test Report: Excel, PDF

- Consumables

- Sample test Mylar

- Oil analysis sample cup

- Sampling pipette

- Test window film

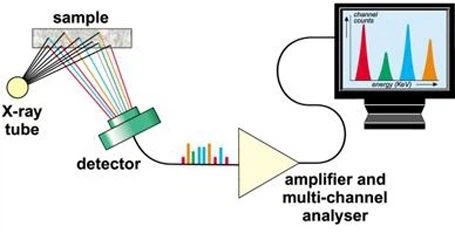

The basic concept of all spectrometers is a radiation source, a sample and a detection system. In EDXRF spectrometers, the X-ray tube acting as a source shoots a sample directly, and the fluorescence coming from the sample is measured with an high resolution detector. This detector is able to measure the different energies of the characteristic elemental radiation coming directly from the sample. The detector can distinguish the radiation from the sample into the radiation from the different elements present in the sample. This separation is called dispersion.

Our products and services help our customers solve complex analytical challenges, improve patient diagnostics and increase laboratory productivity.

Support

- Phone and remote support

- Preventive maintenance and checkups

- Flexible Customer Care Agreements

- Performance certificates

- Hardware and software upgrades

- Local and global support

Training and education

- Training on-site or at our competence centers

- Broad range of basic and advanced courses on products, applications and software

- Analytical services and calibration materials

- Expert (XRF) analyses services

- Oxides and trace analysis

- Customized calibration materials