- Home

- Companies

- Efficiency Scientific Instrument Co., ...

- Products

- ESI - Model Compass 4294 - Portable XRF ...

ESI - Model Compass 4294 -Portable XRF Sulfur-In-Oil Analyser

For ships operating outside designated Emission Control Areas, IMO has set a limit for sulphur in fuel oil used on board ships of 0.50% m/m (mass by mass) from 1 January 2020.

Simply the Best

- Your Portable Lab Element Analyzer that goes anywhere

- Robust bench-top XRF Analyzer offers immediate plug-and-play operation

- High sensitivity with low detection limit

- Meeting new sulfur limits for marine fuel oil

Method compliance

- ASTM D4294

- ISO 20847 ISO 8754

- IP496

Marine Fuels & oils monitoring- Compass 4294 XRF

For ships operating outside designated Emission Control Areas, IMO has set a limit for sulphur in fuel oil used on board ships of 0.50% m/m (mass by mass) from 1 January 2020. This will significantly reduce the amount of sulphur oxide emanating from ships and should have major health and environmental benefits for the world, particularly for populations living close to ports and coasts.

Since 1 January 2015, the sulphur limit for fuel oil used by ships operating in Emission Control Areas (ECAs) designated by IMO for the control of sulphur oxides (SOX) has been 0.10% m/m.

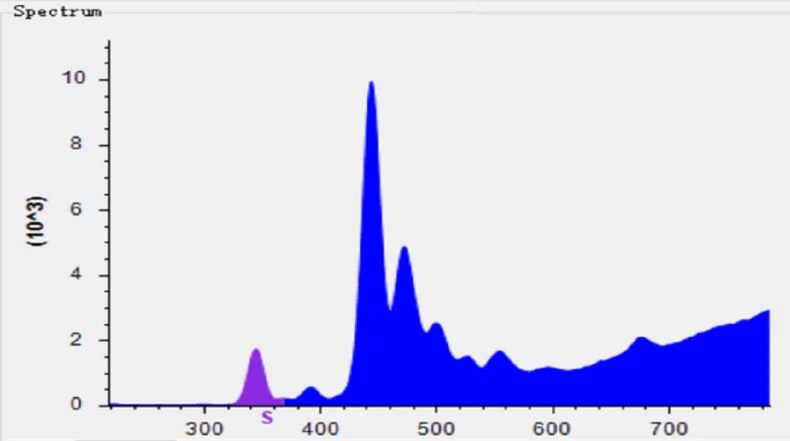

The powerful Energy Dispersive X-ray Fluorescence (EDXRF) Compass 4294 serial Sulfur analyzer of HTek Instrument are capable of more sensitive and precise analysis than can be expected from a laboratory class analyzer. This application note demonstrate the Compass 4294 test performance of sulfur in different oil and fuel samples.

Factory optimized test conditions are set for sulfur analysis. This industry leading technology enabling low detection limits and high precision without the need for consumable helium gas, a vacuum pump, or extensive sample preparation.

The measurement conditions for sulfur in oil are listed in Table below

- Model: Compass 4294

- Tube voltage: 8KV

- Tube current: 200uA

- Collimator: 2mm

- Filter: None

- Helium purge: No

- Test Time: 130S

Test performance Study

Accuracy Study

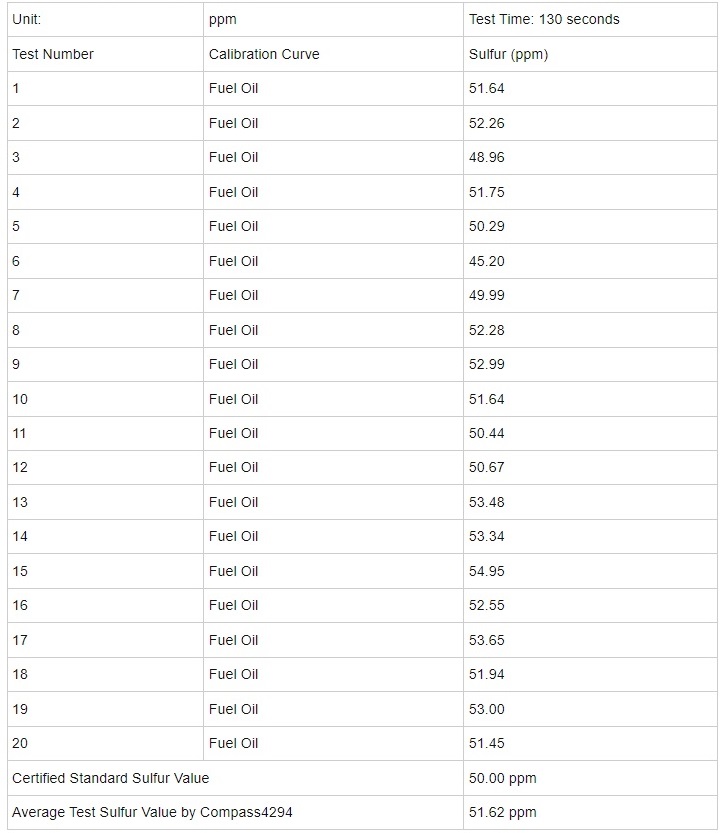

To study the accuracy of Compass 4294, ten measurements were performed on a commercially-available fuel oil reference material containing 50 ppm of Sulfur.

Continues 20 times of test of 50 ppm were conducted and the test value is shown in below report.

Precision Study

To study the precision of Compass 4294, two crude oil samples of sulfur with certified value of 0.1% and 1% were analyzed. The results shown below demonstrate that Compass 4294 delivers precise measurements across a wide range of hydrocarbon sample.

Another important parameter of XRF device is the repeatability of the analysis. The sample was measured 5 times over a period of time. An average, standard deviation (Std Dev) and relative standard deviation (RSD) for sulfur content was calculated from this data as below

A serial of commercial available oil standards were used to calibrate the EDXRF spectrometer at factory. Customer can run the sample test without any further calibration process on-site.

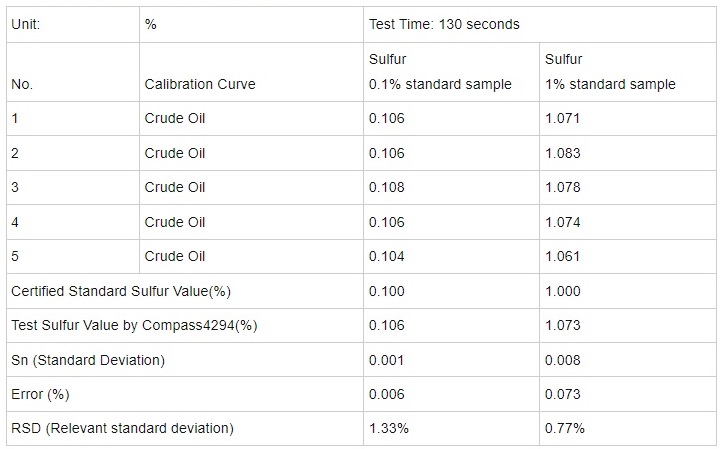

Only four steps are needed to make the measurement. See pictures of how to prepare and put the sample for analysis as below picture

1-1, Prepare the sample cup. The cup was closed on the analytical side with a 6 um thin Mylar film. The same Mylar was also preset on the protection test window platform to avoid any accident sample leak into the analyzer.

1-2, Typically 3-5 ml oil from each standard was poured into the analyzer’s cups up to the fill line.

1-3, Put the sample cup on the compass XRF sample loader, which is perfectly fit wit the sample cup dimension.

1-4, Click the ‘start’ button to run analysis. Results will be shown after 130 seconds.

A set of commercially available heavy fuel oil standards with know sulfur concentrations were used to setup the calibration.

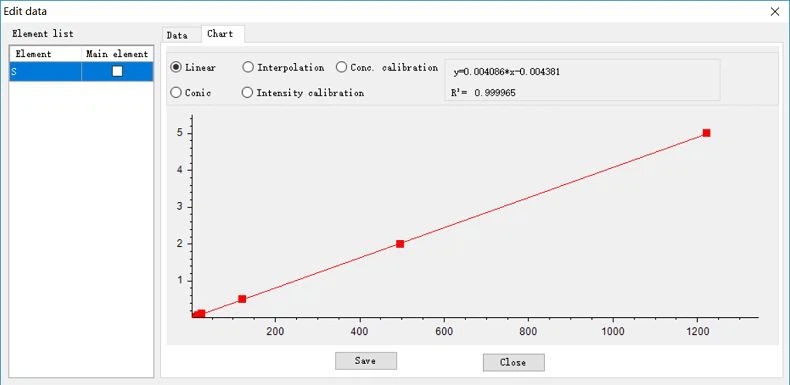

Figures 2-2 below shows the correlation curves sulfur in oil for high concentration ranges in percentage level.

This data was approximated with linear function. R2 is the coefficient of determination. An ideal correlation would have an R2 value of 1.

The red points are sulfur standards: Blank, 0.01%, 0.075%, 0.1%, 0.5%, 2% and 5%. The perfect R2 value(0.999921) demonstrate the good linear with wide concentrate range of sulfur.

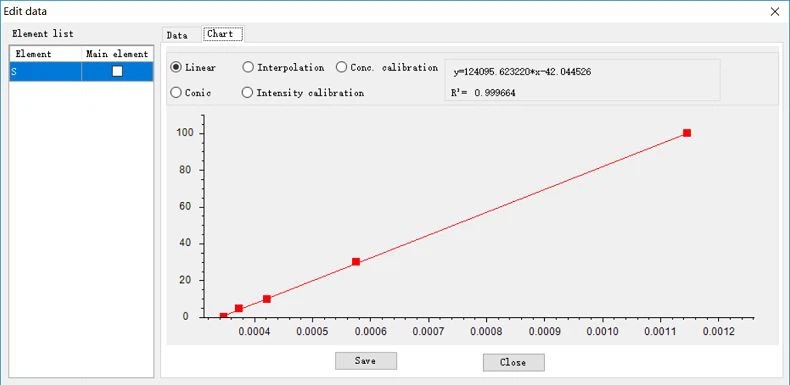

Figures 2-3 below shows the correlation curves sulfur in oil for low concentration ranges in ppm level.

The red points are sulfur standards: Blank, 5ppm, 10ppm, 30ppm and 100ppm. The perfect R2 value(0.999664) demonstrate the good linear and high sensitivity for the low sulfur concentration analysis.

Sulfur analysis using ASTM D4294 and ISO 8754 continues to be an important measurement for refinery and independent laboratories around the world. Global regulation trends toward lower sulfur fuels demonstrate the need for a rapid and precise analysis solution. Based on the test results obtained above, it is proved that the Compass 4294 is capable of measuring sulfur in oil or fuel samples complying with the most strict standard.

On board fuel oil management is an important element of preventing operational issues and sulphur non-compliance.Improper handling of fuel oil on board may lead to non-compliance with MARPOL requirements,even if the fuel oil received was compliant. With it’s compact and portable design, Compass 4294 becomes essential tool to do on board oil quality control for sulfur.