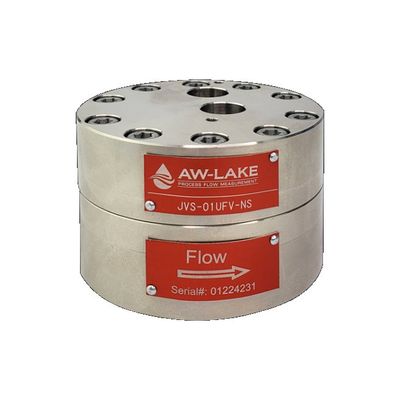

AW-Lake - Model JV-UF -Positive Displacement Flow Meters

Measuring Accuracy: ± 1.5% over full range (viscosity ≥ 5cP), ± 0.5% optional with select sensors: ± 2.5% over full range (viscosity ≥ 5cP) for the JV-01UF

Six Flow Ranges: 0.0005 - 20 gallons per minute | 0.72-28,800 gallons per day (see specs below for ranges of each meter size)

Pressure Rating: Up to 6,000 psi

Calibration: 7-point logarithmic calibration

Output Options: Wide variety of options: see "Choose Your Sensor" tab below for details

-

The JV-UF positive displacement flow meters were designed specifically for low viscosity fluids, as found in the oil and gas or chemical processing sectors. The internal design of the JV-UF meter delivers greater precision than other meters and an expanded list of low viscosity fluids it can handle.

- Eliminate Waste – Maintain repeatable and accurate flow measurement, independent of changing fluid conditions. Track and report usage to quantify product/process quality, pump performance, or material levels.

- Reduce Costs – By using the correct amount of expensive/costly fluids in your process and not overdosing, you can reduce material costs. And with proper lubrication or chemical dosing you can reduce maintenance costs.

- Improve Product Quality – With flow meters that can ensure ±0.1% repeatability, you are able to maintain consistency in your processes by assuring each batch is the same. Despite long and continuous operation, these meters perform at the same level month after month… year after year.

- Operate with Ease – Paired with our smart EDGE family of flow sensors there is one easy to learn set-up procedure available via phone or PC app. Our friendly & knowledgeable staff of Application Engineers are here to help you select the right meter and get you up and running quickly.

- Enjoy Flexibility – The new meters were designed to seamlessly integrate with the EDGE sensors, which are available in panel mount, local mount, and battery, loop, or DC powered displays. Choose your output as well: Frequency or Analog (voltage or 4-20mA), or Modbus.

MEASURING ACCURACY:

± 1.5% over full range (viscosity ≥ 5cP), ± 0.5% optional with select sensors:

± 2.5% over full range (viscosity ≥ 5cP) for the JV-01UF

REPEATABILITY:

± 0.05%

FLOW MEASURING RANGES:

JVx-01UF: 0.0005 to 0.25 gpm | 0.72 to 360 gpd | 0.002 to 1.0 lpm

JVx-12UF: 0.005 to 0.8 gpm | 7.2 to 1152 gpd | 0.02 to 3.0 lpm

JVx-20UF: 0.02 to 2.0 gpm | 29 to 2880 gpd | 0.1 to 7.0 lpm

JVx-30UF: 0.1 to 7.0 gpm | 144 to 10,080 gpd | 0.5 to 25 lpm

JVx-60UF: 0.1 to 20 gpm | 144 to 28,800 gpd | 0.5 to 75 lpm

MAXIMUM OPERATING PRESSURE

up to 6,000 psi

MAXIMUM FLUID TEMPERATURE

Depends on sensor used, refer to sensor page

PORTS:

NPT standard; BSPP optional

MATERIALS OF CONSTRUCTION:

Body: JVM = 303 Stainless Steel, JVS – 316L Stainless Steel

Gears & Bearings: Stainless Steel (DIN 1.4122)

O-Ring: FKM, FFKM, or PTFE

Shaft: 420 Stainless Steel

Bolts: Zinc Flake Coated Carbon Steel (Inconel 718 optional)