Watertronics, Inc.

- Home

- Companies

- Watertronics, Inc.

- Products

- Watertronics - Model SkyHarvester SH-80 ...

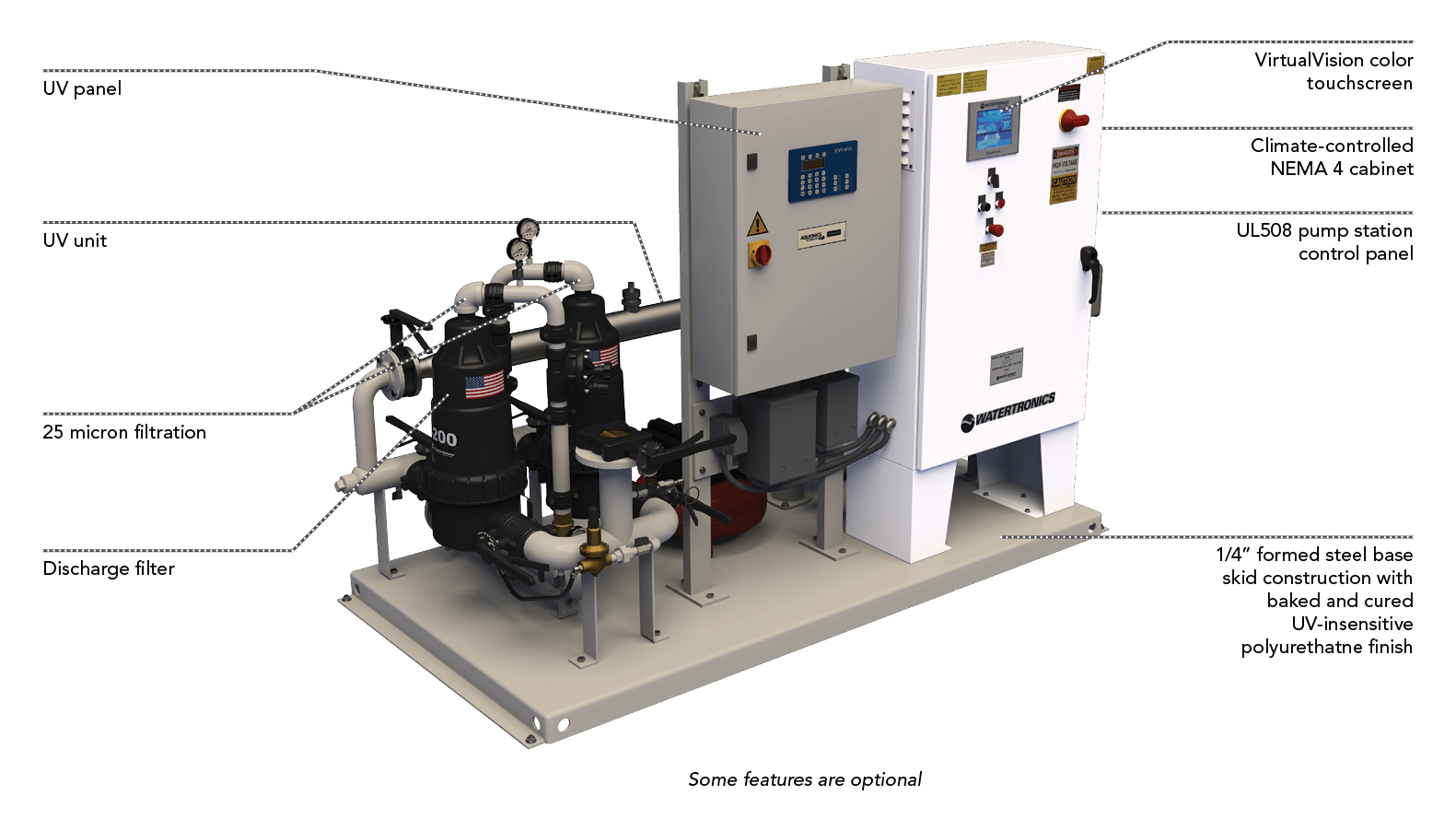

Watertronics - Model SkyHarvester SH-80 -Pre-Packaged Engineered Pump Station for Municipal

The SkyHarvester SH-80 is a pre-packaged engineered pump station featuring integrative controls, filtration and water treatment. This system is available for submersible and flooded suction applications, can pump up to 80 GPM, filter water to 25 micron, and disinfect water with ultraviolet light to a LOG 4 reduction of common microbial contaminants.

Most popular related searches

pump station

pump station control panel

packaged pump station

package pump station

pump station control

water source

tank level control

pressure relief valve

pressure regulator

flushing valve

- Application: Submersible or Flooded Suction

- Flow: Up to 80 GPM

- Motor Options: 5 HP & 7 1/2 HP

- Voltage: 230/1 Phase/60 Hz, 208/3 Phase/60 Hz, 230/3 Phase/60 Hz, 460/3 Phase/60 Hz

- Color touch screen

- VFD with Watertronics proprietary PLC logic

- Integrated filter controls

- Tank level control and display in inches & gallons

- Displays and controls up to 3 alternate water sources (city, well, other)

- Displays total harvested and alternate water used

- Single set point or flow based pressure regulation

- Building management communication via serial MODBUS RS232 or RS485

- DV/DT long motor lead filter (when used with submersible pump)

- Reversible filter flush line

- Pressure relief valve

- ¼ inch formed steel base construction

- Sch. 40 steel piping

- UL 508 pump station control panel

- Built to FCC Part 15 Standards

- Full dynamic flow, pressure and operation testing prior to shipment

- Tank pre-filter flush valve and logic

- Alternate water source connection options (both with pressure regulation):

– Direct to distribution (engages automatically upon power failure)

– Tank fill (accommodates up to 3 alternate water sources) - UV disinfection with auto wiper, intensity monitor and UV cooling valve

– 0-66 GPM @ 32 mj/cm2 @ 75% UVT

– 67-80 GPM @ 32 mj/cm2 @ 85% UVT - Integrated UV logic

- Automatic discharge filtration

– 25 micron when used with UV, 100 micron when used without UV - Composite or stainless steel discharge filters

- Automatic tank recirculation valve

- Bladder tank – ASME or non-ASME rated

- WaterVision® Cloud remote telemetry

Skid Construction

Reinforced 3/8 in. formed steel base construction, with rounded seamlessedges to resist rustand corrosion. Flat skid surface provides ease of maintenance and reduces water and debris collection.

Painting

Three-step epoxy coat paint process for maximum durability:1) Steel grit blasting2) Two-part epoxy primer3) Polyurethane top coat is applied and baked to assure adhesion

Dynamic Testing

Prior to delivery, eachstation is tested to site specific conditions for full dynamic flow, operation and 7-point vibration performance in our 88,000 gallon factory test pit.