- Home

- Companies

- Watertronics, Inc.

- Products

- Watertronics - Model SkyHarvester- ...

Watertronics - Model SkyHarvester- SH-MICRO -Pre-Packaged Engineered Pump Station for Rainwater

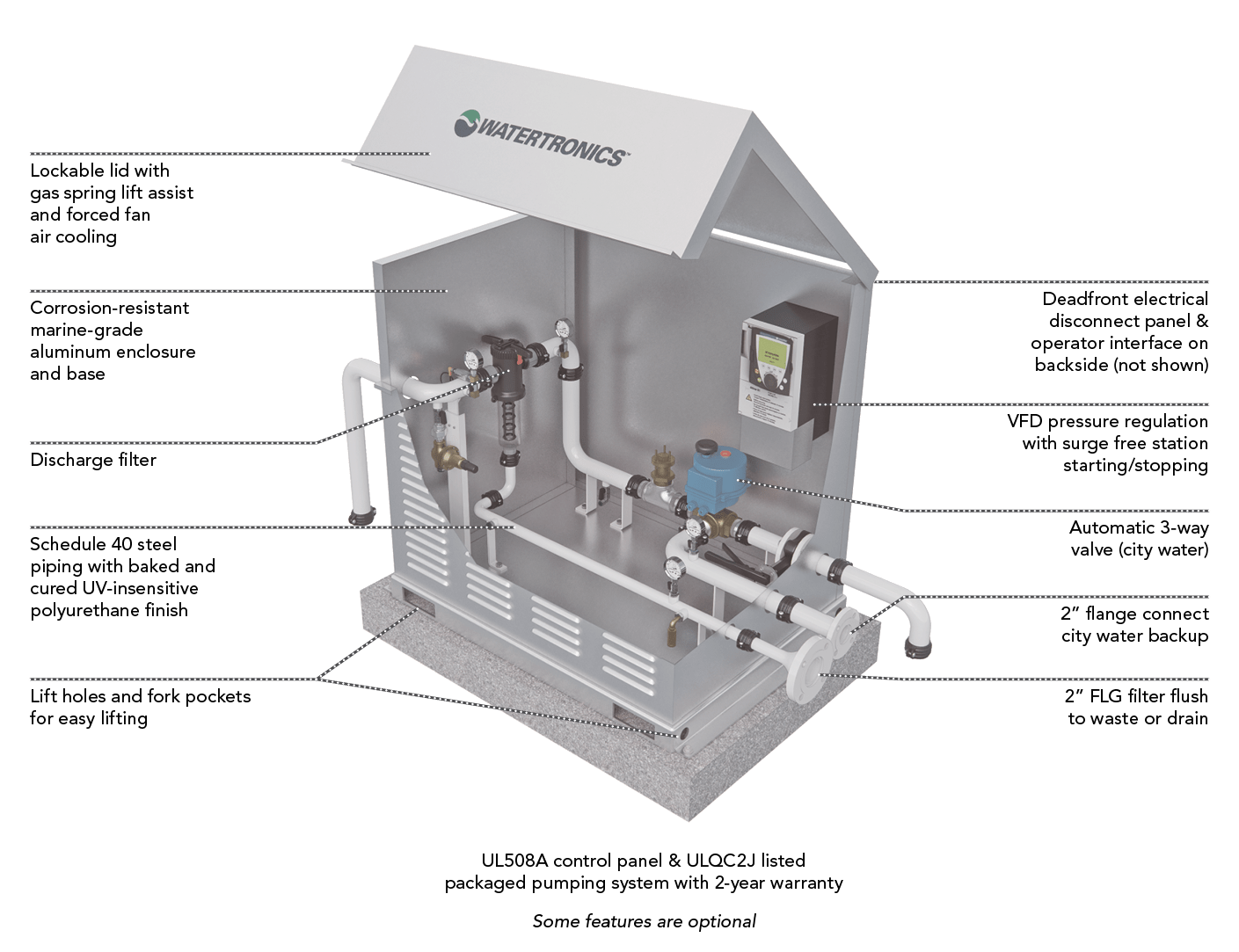

The SkyHarvester SH-Micro is a pre-packaged engineered pump station featuring a submersible pump, VFD pressure regulation, discharge filtration, and level controls. With the ability to pump up to 60 GPM, filter water to 100 micron, and control a back-up water supply in the event harvested water is not available, the SkyHarvester SH-Micro can deliver harvested water for drip and micro-spray irrigation systems at a constant pressure under varying flow rates to meet today’s commercial needs.

- LED keypad operator interface

- VFD with single set point pressure regulation

- Pressure drop start

- Pressure relief valve

- DV/DT long motor lead filter

- HDPE pump flow inducer sleeve with intake screen & flexible discharge hose

- Tank level and backup water level indication via float switches

- Ability to control 1 alternate water source

- Displays total water pumped in GPM and total gallons used

- Manual discharge filter with 100-micron screen

- Sch 40 steel piping with baked and cured UV-insensitive polyurethane finish

- Marine-grade aluminum station enclosure and base with lockable lid, forced fan air cooling, fork pockets and gas spring assisted lid lift

- Dead front high voltage disconnect panel

- UL 508A control panel and ULQCZJ listed packaged pump station

- Built to FCC Part 15 Standards

- Full dynamic flow, pressure and operation testing prior to shipment

- 2-inch inlet & discharge drop pipes

- 24 VAC remote start relay

- City water backup tank fill valve (ship loose) with tank level controls

- City water direct 3 way valve and controls (on skid)

- Outdoor vandal resistant red alarm light

- Opto coupler

- Enclosure heater

Dynamic Testing

Prior to delivery, eachstation is tested to site specific conditions for full dynamic flow, operation and 7-point vibration performance in our 88,000 gallon factory test pit.

Rainwater Catchment

The rainwater catchment area can be any surface that water falls upon or any device that discards water. Hard surface roofs, green roofs, and parking lots are a few of the most common rainwater collection areas. Others include synthetic turf, children’s splash pads, cooling towers, and air conditioning units.

Rainwater from hard surface roofs can be used for:

- Irrigation

- Toilet flushing

- Wash systems

Rainwater from parking lots and green roofs is typically used only for irrigation. We employ various treatment methods if working with parking lots or green roof water, in order to reach the standards for interior building use. When looking at a potential rainwater harvesting site, one can assume 620 gallons of water per 1,000 square feet of hard-surface collection area per one inch rain event. However, the world is an imperfect place and efficiency factors must be added to account for inefficiencies in the conveyance system and tank pre-filters.

Pre-Filtration

A pre-filter is used to remove dirt, debris, and organic matter from the harvested water. This keeps the tank clean resulting in better water quality and less tank maintenance. The best way to filter the water is at the source. The better the filtration upstream, the less money/effort will be required for filtration downstream.

Most all filters work on an efficiency principle, which means that depending on flow rate, all or a portion of the water is filtered before entering the storage tank. Screen sizes can vary from 350 micron to 700 micron depending on actual filter. Larger units that collect water off a parking lot have larger screen openings and typically include a form of oil/water separation.

Some filters can be automatically cleaned (or flushed) by sending pressurized water from the pump station to a spray head located on the filter body. Flushes are initiated via a daily timer on the SkyHarvester control operator interface.

The filters below are two frequently used options in SkyHarvester systems. Each filter uses a stainless steel screen to prevent debris from entering the storage tank. These filters have a screen size of 350-700 micron and are self-cleaning / flushing units.

Below shows a complete SkyHarvester system installed at Coca-Cola Distribution in Lexington, Kentucky. Being a single-source supplier, our scope begins at the pre-filter upstream of the storage tank and ends the connection to the water distribution system. We integrate the pre-filter itself, storage tank(s), pump station, discharge and treatment, and the controls to operate the entire system seamlessly.

This close-up below of pre-filtration at the University of Wisconsin, Milwaukee is located in a below-ground parking garage where water is filtered from seven stories above. It is then delivered to the below ground storage tank just on the other side of the concrete wall for landscape irrigation.

Pumping

The pump station is the heart of the water harvesting system. Pumps can be submersible (located in the tank or wet well), or self-enclosed horizontal centrifugal.

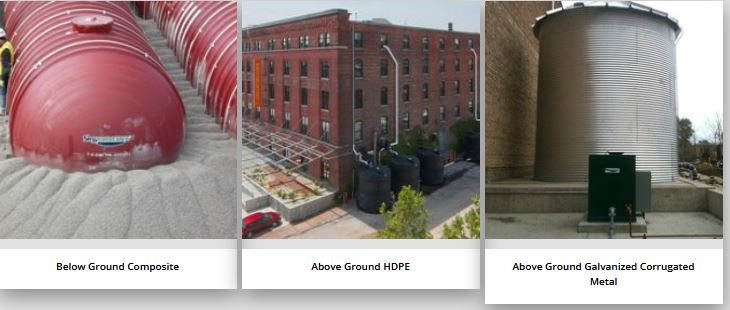

Storage

Selecting the proper storage vessel is perhaps the most important decision that must be made as it directly determines the overall effectiveness of your water harvesting system. Tank size, material, and placement can mean the difference between running on 5% or 95% harvested water and are determined via a formula that accounts for average rainfall, collection area, and other available water sources, as well as consumption requirements.

SkyHarvester offers the following storage options:

Controls

The controls are what turn the user into a true water manager. Our advanced control technology tells the pump when to start & stop and controls all ancillary components such as tank level sensor, automatic filtration, injection equipment, etc. SkyHarvester systems operate independently without human intervention and are self-protecting systems.

Post Filtration & Water Treatment

We custom design the post-filtration and water treatment to meet each project’s final water use requirements. If used inside the building, disinfection of the water is often necessary. Standard drip irrigation typically requires filtration to the 100 micron level through screening. Other water treatment methods available include UV, Chlorination, Media Filtration, Ozone, Ultra-Filtration, Reverse Osmosis, and Deionization.

Replenishing Water

Most of our customers include a replenishment water source in their systems in order to protect against water shortages. It is important to carefully consider the design of the replenishment water system, as errors here could lead to major liabilities for the customer – particularly in the case of toilet flushing applications. Having a reliable replenishment water source is important for protecting the health of various valuable investments, such as expensive landscape plantings and greenery.