Premier Tech

- Home

- Companies

- Premier Tech

- Products

- Premier-Tech - Model CHRONOS VPF Series ...

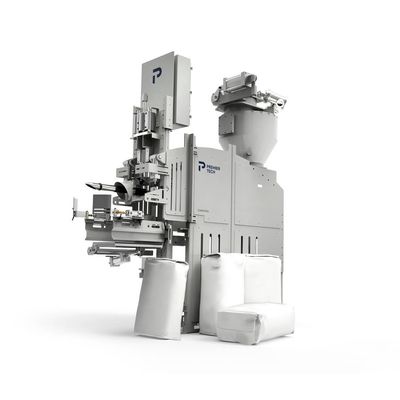

Premier-Tech - Model CHRONOS VPF Series -Force Flow Air Packer

FromPremier Tech

The Force Flow Air Packer (former 725 Series) offers excellent weight accuracy and simple operation. The filling and weighing system is fully integrated into a single machine and under a single interface.

Most popular related searches

bag filling system

forced air

weight indicator

dust explosibility

particle sizing

explosive environment

metal detection system

dust explosion

weighing system

well construction

This pneumatic packer uses air to bag products, providing faster filling. A versatile packing solution, this machine can handle fine powders, flakes, pellets, and granules with a particle size of 3/8`` or smaller, such as chemicals, minerals, and food products.

Multiple units may be banked together under a single hopper to provide higher production rates. A version with an integrated sealer mounted to the packer’s frame is also available, ensuring clean operations and improved bagging accuracy.

- Speed: up to 10 bags per minute (per spout)

- Bulk materials: fine powders, flakes, granules, pellets

- Bag types: valve

- Bag materials: paper

- Bag weight: 22 to 110 lb (10 to 50 kg)

Accurate

- Excellent weight accuracy (2 ounces at two sigma for many products)

- Bulk and dribble product flow for a slow “top-off” that improves accuracy (electronic models only)

- Inflatable sealer closes off the gap between the filling tube and the bag’s valve to minimize dust during filling

Ease of use

- Easy changeover with a quick-drop bottom for clean-out between runs

- Low maintenance with no moving parts in the product’s path

Well-constructed

- Small footprint as multiple machines can be banked together under one bin

- Laser cut and bolted frame

- Minimal ledges to prevent product or dust build-up

- Plumbing and wiring is internally routed and protected by the sleek steel framework

- Designed to be used with the Middle Range NXT and MP family of Electronic Weight Controllers

- Stainless steel product contact parts

- Atmospheric configuration for lowered machine cost

- Plug/stack configuration for handling granular or pellet products

- Potbelly-style chamber for low-head applications

- Built for use in II-G-1 and II-G-2 dust explosion environments

- Metal detector mounted around gum rubber filling tube behind fill spout

- Typical footprint: 32" L x 16" W x 62-93” H (813 x 406 x 1575-2362 mm)

- Electrical requirement: 110 V / 1Ph / 60 Hz / 5 amps, Saskatchewan, Canada S0A 2B0