Presona - Model LP 100 DH S -Prepress Technology Baler

The baler: Robust design with highest possible reliability. User and service friendly. Optimized bale size and big feed opening. Press chamber floor made of 25 mm high-tensile steel. Main press top and bottom with cam design for better sealing. Main press rolling on four heavy-duty wheels guided on wear rails mounted on the press bottom. Main press with sturdy wear blocks on sides and top. Heavy duty bearings for the pre-press shaft. Detection system of the pre-press position during operation to secure a safe interlock of inspection hatches and protection covers.

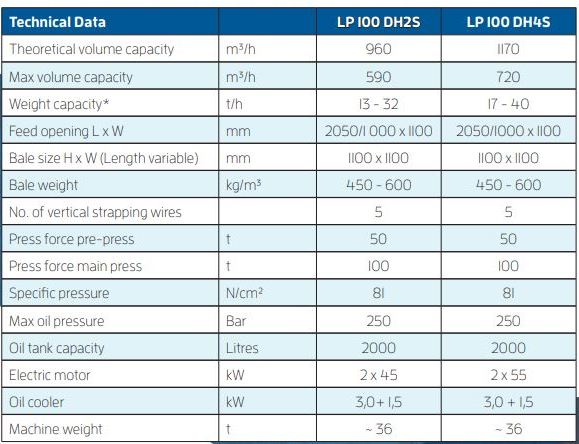

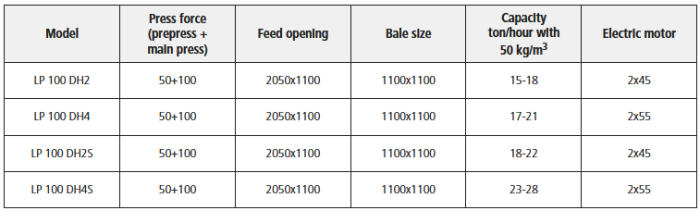

With its big feed opening (2050 x 1100 mm) and the unique two-step prepress feature the LP 100 baler is designed to handle bulky materials, like big cardboard boxes, with ease. The prepress can be adjusted to create a smaller 1000 x 1100 mm press chamber, making this baling machine very versatile. The baler is available in two versions in regards to bale size: LP 100 DH: W 750 x H 1100 x L variable mm. LP 100 DHS: W 1100 x H 1100 x L variable mm. The LP 100 can process up to 45 tonnes/hour and has a combined press force of 150 tonnes.

Materials

- Aluminium/tin cans

- Cardboard

- Hollow containers and plastic bottles

- Mixed paper

- Plastic film

- Newspaper

- Print and plastic waste

- RDF, SRF and MSW

Strapping Material

- Metal

- 2-step prepress for power saving precompaction, adjustable for variable width of the feeding hopper.

- Ensures that the material always produces a constant counter pressure in the main press chamber.

- Up to 30 % lower energy consumption compared to a baler without prepress.

- No knives on the main ram, no risk for material jamming between knives and press plate.

- All of the press force utilized for material compaction.

- Increased volume capacity of the machine; the number of prepressing operations may be determined depending on the material to be baled.

- Guarantees an even density throughout the bale = square bales.

- Makes it possible to bale big size material without using a shredder.

- Makes it possible to bale most recyclables to dense, square bales.

- Low service and maintenance costs.

- Main drive motor 2 x 45 kW (100 DH2) and 2 x 55 kW (100 DH4) with a double hydraulic pump system

- Oil level control system

- Oil temperature transmitter - oil temperature indicated on control panel screen

- Oil cooler

- Oil heater (optional)

- Strapping system with five vertical needles.

- Simple and reliable twisting unit with an eccentric drive, service friendly, easy access.

- The number of twistings and twisting force adjustable for an optimized relation between wire consumption and stability of the ready bale.

- Very short pigtails (wire ends) - no waste of wire.

- Wire guiding system for big wire coils.

- An additional strapping unit with three horizontal wires for maximum bale weight when baling expandable materials (option).

- PREMI 2.0 HMI Interface system with a fixed Internet connection for operation control and monitoring, presetting of 20 baling programmes.

- Easy operation with a 12” colour Touch Screen

- Quick couplings for quick and safe installation

- A photocell system for baler and conveyor control

* At a material pre-bale density of 30 - 100 Kg/m³

Performance rates and bale densities are subject to moisture, material pre-bale densities, feed rate and other variables when baling.

As part of our continuous product development, specifications are subject to change without notice.

- This baler is available with these options: