- Home

- Companies

- Interplex Holdings Pte. Ltd.

- Products

- Interplex - Press-Fit Technology

Interplex - Press-Fit Technology

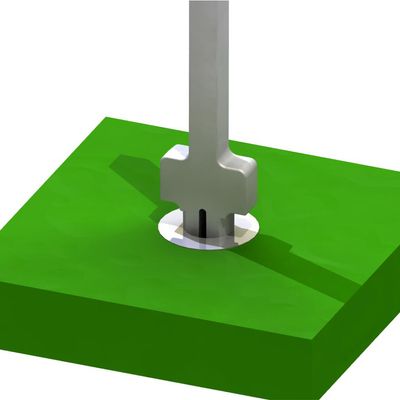

As the global leader in solderless Press-Fit Technology, Interplex has been producing Press-Fits for top-tier customers for over a decade. Our patented automotive and high reliability Press-Fit Solderless Interconnect designs are validated against IEC 60352-5 and IPC-9797 and tested for high performance in harsh, high temperature automotive environments.

Robust Connections

Press-Fit provides strong, solderfree, repeatable, and highly reliable interfaces with high normal forces.

Reduced Process Cost and Risk

Press-Fit eliminates secondary soldering.

Whisker Mitigation Option

Interplex provides industry leading whisker mitigation electroplating technology, IndiCoat™, as a finishing option for our customizable Press-Fit components.

Eliminates Soldering Quality Issues

Press-Fit joints are not subject to quality problems associated with solder – such as cold spots, voids, splatter and cracks.

Optimized for Automation

Press-Fit Technology is optimized for use in automated assembly techniques with integrated force monitoring of the push-in process to guarantee consistent assembly process results, without operator-dependent variability.

High Repeatability and Reliability

Interplex Press-Fit interconnects offer highly repeatable assembly results and high reliability connection joints.

Wide Range of Configurations

Interplex’s full portfolio of Press-Fit interconnection system ranges from 0.4 mm Press-Fit for high density signal connectors up to 1.2 mm thick Press-Fit for high power applications.

Optimized Electrical and Mechanical Performance

Press-Fit’s compliant interface design is optimized to provide unmatched electrical and mechanical characteristics within each solderless connection.

Designed for Configurability

Flexible tooling enables to be integrated in connectors, solder tails, sockets, jumpers/shorts

Excellent Thermal Performance

Press-Fit’s high normal force interface accommodates movement of CTE mismatch to deliver excellent performance during high temperature cycling conditions.

RoHS Compliance

All Interplex Press-Fit components are RoHS compliant

- Aerospace

- Automotive

- Commercial Transportation

- Personal Mobility

- Maritime

- Energy

- Industrial

- Electrification of Vehicles

Solderless Press-Fit Terminals for Automotive Applications

This technology supports the assembly of a terminal or electrical lead with a PCB plated-through hole, where an electrical connection is created and maintained without the application of solder.

Custom Connectors with Press-Fit Terminals

Our Press-Fit technology is used in connectors and headers that make custom interconnects directly from the PCB to a mating connector.

Press-Fit Module and Sensor Enclosures

Manufacturers utilize our solderless Press-Fit technology in a variety of control modules and sensors. Our technology helps customers design-in low-cost, high-quality products by seamlessly integrating the complete connection system into the enclosure package, eliminating the need for secondary soldering operations.

Card Edge SMT Press-Fit Connector System

Interplex’s SMT card edge connector system employs a discrete SMT component, creating a solderless Press-Fit card edge connector system for daughter card applications. It uses Interplex-tested and proven 0.4mm or 0.64mm Press-Fit technology. Automotive manufacturers utilize Press-Fit technology in control modules, switches, fuse receptacles, junction boxes, hybrid inverters, a myriad of sensor and connector applications, and other engine and passenger compartment applications. Our solderless Press-Fit technology is fully tested to meet the automotive industry’s stringent operating requirements for vibration and temperature.

A Trusted Global Solutions Provider

Interplex’s Product Development team works closely with customers globally to develop Press-Fit & IDC solutions tailored to specific end application needs. For example: Direct insert terminals, customized connectors and headers, Press-Fit PCB connectors, custom-molded modules, power lead frames and other electronic packaging solutions.

We leverage our expertise in product design, applications engineering, manufacturing and automation to help customers create the proper turnkey solution for any particular application. Our global footprint vertically integrates Press-Fit & IDC stamping, plating, molding and assembly to provide the highest level of design flexibility, cost-effectiveness and production scalability.