- Home

- Companies

- Kordes KLD water and wastewater systems ...

- Products

- Kordes Variant - Pressure Drainage Pump ...

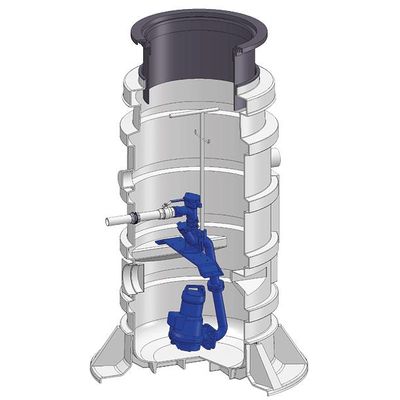

Kordes Variant - Pressure Drainage Pump Station with PE Tank

VARIANT pump station for one- and two-family houses: Robust polyethylene LDPE shaft. Covers up to class D (truck passable). Pumps with traverse suspension. Single or double unit. Armatures in DN 40. Armatures cast iron or stainless steel. Buoyancy control (optional). Fully electronic control unit. External column or building installation of the control unit. Flushing connection (optional). Vacuum breaker (optional).

Shaft systems

LDPE pump station

- Inlet depth: 1.26 - 1.96 m

- Installation depth: 1.78 - 2.48 m

- Shaft diameter: 800 mm

- Storage volume up to inlet: approx. 300 liters

- Inlet connection: 2 x KG DN 150

- Connection technology, ventilation: 2 x KG DN 100

- Telescopic dome for exact height adjustment

- Plastic covers up to 200/600 kg or as BEGU class B/D in Ø 600 mm

- Ventilation

- Buoyancy protection

Cast iron armatures in DN 40 with traverse suspension

- Armatures made of spheroidal cast iron with powder coating

- Piping made of stainless steel

- The coupling foot is located on the traverse

- The pumps can be easily inserted into the coupling from above without entering the shaft

- Pump removal is possible at any time even without shutting off the slide valve

- The non-return ball valve prevents the backflow into the pump station

- The pipeline can be closed by a gate valve for repair purposes

- Flushing connection, vacuum breaker (optional)

Stainless steel armatures in DN 40 with traverse suspension

- Corrosion-resistant armatures and piping made of 100 % stainless steel

- The coupling foot is located on the traverse

- The pumps can be easily inserted into the coupling from above without entering the shaft

- Pump removal is possible at any time even without shutting off the slide valve

- The non-return ball valve prevents the backflow into the pump station

- The pipeline can be closed by a gate valve for repair purposes

- Flushing connection, vacuum breaker (optional)

For optimum flow rate and flow velocity, armatures, pressure lines and pumps must be precisely matched to the requirements of your construction site. Our product range extends from pumps with cutting impeller system for small wastewater volumes with admixtures, to pumps with free-flow impeller system. Both variants are available with and without explosion protection. For certain types of wastewater, pumps with special resistance to corrosive substances are also required.

Do not leave the right selection of your pump to chance and let us support you in the correct design. So that we can offer you the pump that is best suited for your construction site, we work together with the leading manufacturers of wastewater pumps. Our valve system can be combined with almost all common pumps with DIN flange.

Our control units reliably switch and monitor your VARIANT pump station. The control unit can be installed inside by wall mounting or outside in an outdoor column. According to your application, we offer you a coordinated concept consisting of control unit, level measurement, armatures, pumps and shaft.

Control unit CEB / CDB

- Connection up to 5,5 kW / 9 A

- Dimensions: W/H/D = 265 x 270 x 145 mm

- Level measurement: dynamic pressure, float switch, pressure probe

- Touch color display illuminated

- Error memory with full text display

- Manual - 0 - Automatic setting

- 3 potential free contacts

- GSM modem with qualified messages (optional)

- Operating hours recording, current measurement, thermal monitoring of pumps

- Messages: Overcurrent, overheating, high water, runtime monitoring

- Air bubbling for dynamic pressure measurement (optional)

- Power failure monitoring by accumulator (optional)

- Optical and acoustic alarm message

- Motor protection switch

- Main switch

- External locking of pumps possible

Control unit BEN / BDN

- Connection up to 5,5 kW / 9 A

- Dimensions: W/H/D = 200 x 220 x 110 mm

- Level measurement: dynamic pressure, float switch

- Text display with illuminated digits

- LED error display on front cover

- Manual operation with push button

- 1 potential free contact

- GSM modem with a general error message (optional)

- Operating hours recording, current measurement, thermal monitoring of pumps

- Messages: Overcurrent, overheating, high water, runtime monitoring

- Air bubbling for dynamic pressure measurement (optional)

- Power failure monitoring by accumulator (optional)

- Optical and acoustic alarm message

- Electronic engine protection