- Home

- Companies

- PRIMA POMPE - by FINVALORI

- Products

- PRIMA - Submersible Motor

PRIMA - Submersible Motor

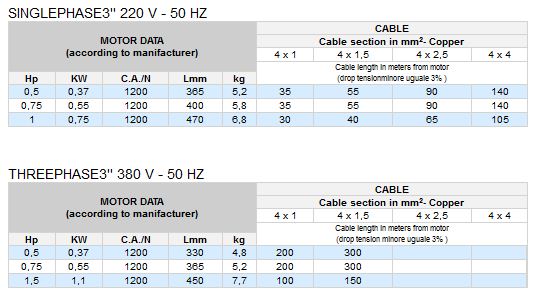

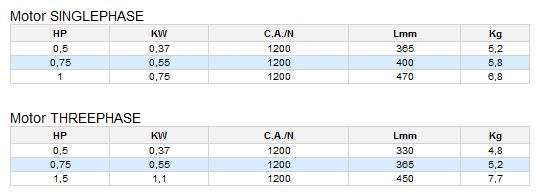

3`` types: asynchronous, bipolar; s.steel, external jacket; F class insulation; IP58 protection. Threephase or singlephase with capacitor start; voltage, current, frequency, power and torque data according to international rules. Coupling to body pumps according to NEMA STANDARDS; axial load to be coupled in compliance with hydraulic performances. For voltage Ud different from those indicated in the table, the cable lengths must be multiplied by the ratio (Ud/220)² if monophase or (Ud 380) ² if threephase. To avoid short circuits and overloads execute electrical plant of the electro pump with materials and protection according to actual rules. Overloads, line drops over 3% can be avoided by using correct start system (max 20 starts/hour well distributed). Used cables according to standards with good insulating features.

Rotation: clockwise looking at the pump, motor side. Install the pump into artesian wells DN 76mm for 3" types, DN 100mm for 4" and DN 150/210mm for 6" be sure that the electropump is completely filled (clean waters, max temperature 45°C).

If there is sand (max 40 g/m3) beed the well before installing the electrosubmersible pump.

Do not run the pump with closed discharge head for more than 2 minutes.

Before starting the electro submersible pump for the first time check that air is nomore coming out from discharge pipe, gradually open the flood gate then start. Install control panels for electrosubmersible pump with level sound to prevent dry starts. With high lift plant of electro submersible pump or with pression accumulations install anti water-hammer valves. If the unit doesn`t work for a long period, frequently start the electro submersible pump.