- Home

- Companies

- Wuxi Qiuyuan Environmental Engineering ...

- Products

- BIOETP - Primary Clarifer/Secondary ...

BIOETP - Primary Clarifer/Secondary Clarifier

Clarifiers are widely installed in sewage treatment plants, water treatment plants, pulp and water plants, mining facilities and anywhere else where there’s a large amount of water that needs to be treated prior to being discharged into the environment, or be recirculated and reused again.

Types of clarifie

Conventional Clarifier: A conventional clarifier is a gravity sedimentation tank. They are available in rectangular or circular configurations.

Suction Clarifier: Suction type clarifier use a vacuum system to collect the sludge from the bottom of the tank. They are used for secondary and final clarification processes.

Working Principle and Proces

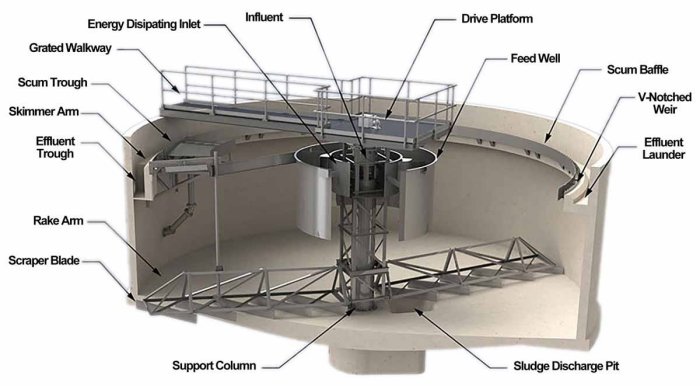

Influents enter into the the energy dissipating feed well which locating in the center of the clarifier. By the work of baffle plates, the velocity of the flow slows down and the liquid starts to flow downwards

A clarifier can be split into three zones: inlet zone, settling zone and outlet zone. The settling zone is where the solids, which are heavier than the liquid, will sink to the bottom of the clarifier to form sludge, and floatable solids will accumulate on the surface of the water as scum. A rake with scraper blades will rotate gently to push the sludge inwards radially to a sludge pit where the sludge will be sucked out of the clarifier for further treatment, usually dehydrated by a screw press dehydrator.

A scum skimmer will push the scum outwards radially to outside periphery of the clarifier to a scum trough. A scum baffle shall be installed to stop scum going to clean water outlet. The effluent, after removing approximately 90 to 95% of the settleable solids and approximately 40% to 60% of the suspended solids, is now quite clean. It flows through V-notched weir as thin film water to effluent launder for further treatment.

QYC series clarifiers are widely installed in sewage treatment plants, water treatment plants and industry wastewater treatment plant. Quality and well-selected brands for all parts of machine to ensure life-time trouble-free service. Our experienced engineering teams are able to delivery latest technology & designs to meet clients’ requirements.

- Construction material : Circular/rectangular

- Size : ranging from 3m to 60m

- Depth : Side Water Depth from 2m to 7m

- Mounting type : Bridge mounted/Pier mounted

- Drive type : Central Driven or Peripheral Driven

- Bridge type : Full bridge or half bridge

- Construction material : Carbon steel or stainless steel

- Surface Coating : Epoxy painting, coal tar painting or FRP painting