- Home

- Companies

- Procal - Parker Hannifin Corp

- Products

- Procal - Model 1000 - Analyser Control ...

Procal - Model 1000 -Analyser Control Unit and Reporting from CMS

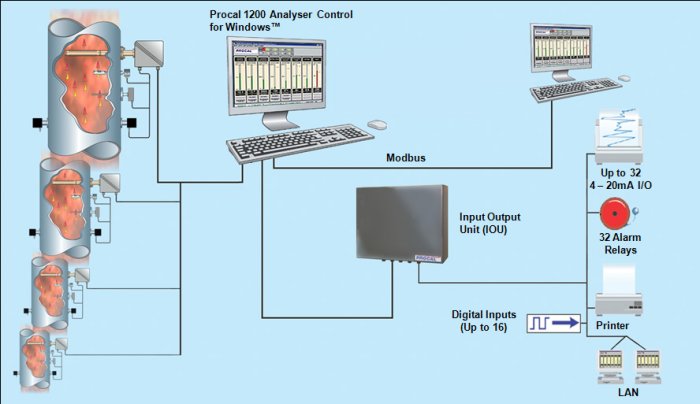

The Procal 1000 Analyser Control Unit (ACU) controls and processes the raw data from up to six Procal Continuous Emission Monitoring systems and generates, displays and transmits concentration readings in customer specified units.

The Procal 1000 series of Analyser Control Units form the hub of an advanced Continuous Emission Monitoring System. In addition to collecting data from Procal’s advanced range of Emission analysers, it is configured to receive data from complementary devices, e.g. Dust / Opacity, Oxygen and Flow. This enables the system to display gas concentrations on a normalised basis and, if required, in mass units eg Kg/hour.

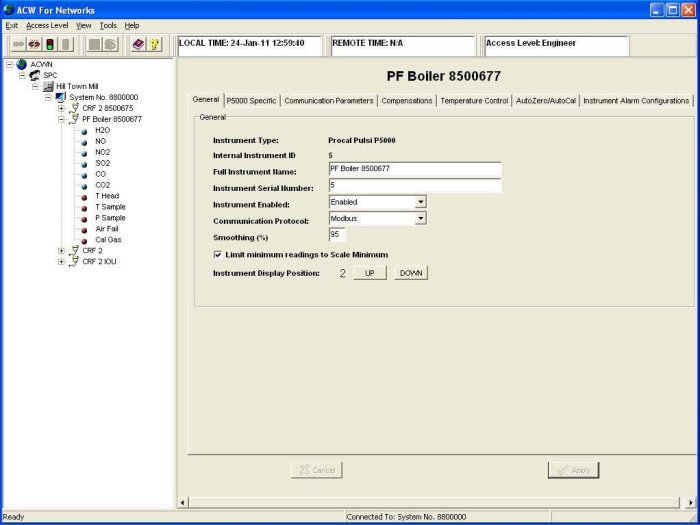

The Analysers communicate via a serial data link to a PC running Procal 1000 software which can located up to 1200m from the CEMS. To facilitate ease of operation, the intuitive software is designed to utilise either a pointing device or touch screen for all operator functions. The Procal 1000 is capable of supporting up to six Procal Analysers with associated third party devices.

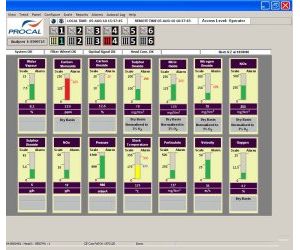

Data from up to sixteen channels per instrument can be presented on an individual front panel comprising:

- Measurement value in digital and analogue form

- Alarm configuration and levels

- Alarm status

- Normalisation (equivalent correction for carbon dioxide or oxygen).

- Wet / dry basis reporting.

- System diagnostic alarm with access to specific detailed displays.

- Autozero / calibration status

- Analyser connection status and analyser-specific status panel screens for each instrument.

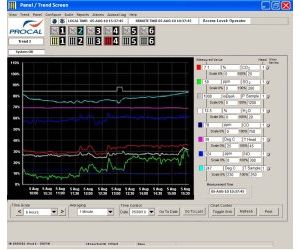

Up to eight channels of historical data from any instrument are presented in X-Y chart form. On the right hand side of the chart is the identification of each measured component, its scale, the colour of the trace and the measured value.

The date and time at which the measurement was taken is indicated in the Measurement Time box in the lower right hand corner of the screen.

This time will initially be the current time (Now) but by use of the Time Scale scroll and mouse control, a dotted cursor can be moved to any part of the screen for any time and the measured value at the point selected. The Averaging Period box allows the rolling average of the measured value to be varied. Additional trend screens can be added by the User.

Reports can be generated to meet the requirements of the majority of national environmental authoritys’ reporting requirements and include:

- Calibration status report (zero and cal report)

- Trend reports

- Hourly, daily and weekly averaging reports

- Excursion report

Special reports can be configured - please consult Procal directly

- Supports up to six Procal analysers each with up to four third party inputs.

- Network ready allows data from multiple Procal 1000 to be displayed on a plant supervisory Procal 1000.

- WAN capability, allowing remote access for reporting and site support.

- MODBUS slave connectivity to plant DCS

- OPC Client ready (PC internal or over network)

To comply with environmental agency’s protocols the system incorporates three levels of password protection.

The data from each analyser is displayed on an individual test screen. The screen displays data from each measured signal, including any offset, and the current calculated concentration. In addition, it displays the analyser temperature, sample temperature, sample pressure, and up to three input signals from external sources, such as particulate, oxygen, velocity, and a set of channels derived from these measured channels.

Print Function - USB & parallel printer port

Data Dump Facility - USB memory stick

MODBUS - Four wire RS485 Full Duplex, Standard MODBUS Slave OPC & ODBC

LAN - Ethernet two ports 10 / 100 / 1000 Mbps

Up to 32 Current Input / Outputs 0 - 20 mA / 4 - 20 mA, each galvanically isolated from ground and from each other. Normally only fitted with the same number of outputs as the number of Procal ranges, third party intruments connected to the system can also be allocated outputs.

Up to 32 Relay Outputs Volt-Free 28V dc 1A (n/c or n/o selectable) for channel alarms, analyser `fault’ relay, and for other functions.

Up to 16 Digital Inputs 24V / 20mA logic or Contact closure detection Link Selectable.

Data Storage: 140GB - In excess of eighteen months data storage on a four analyser system

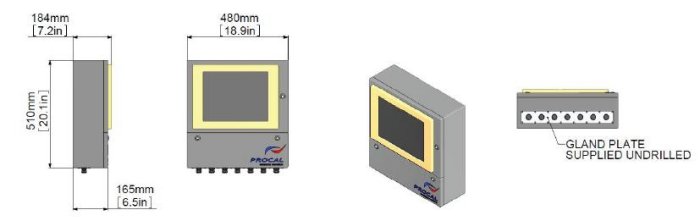

Enclosure: Polyester powder coated mild steel, stainless steel panel PC bezel. Sealed to IP 65/NEMA 4X

Operating Environment: Operating temperature range:-10°C to +55°C (+ 14°F to + 130°F)

Enclosure Classification: Non-hazardous area

Services Required: 90-264Vac 47-63 Hz 70W Typical / 160W Maximum (Dependent on options fitted)

Weight: 23kg (501 lb)

Dimensions: 510mm(H) x 480mm(W) x 165mm(D) 20.1”(H) x 18.9”(W) x 6.5”(D)