- Home

- Companies

- Proco Products, Inc.

- Products

- Proco ProFlex - Model Style 710 - ...

Proco ProFlex - Model Style 710 -Flanged Rubber Check Valve

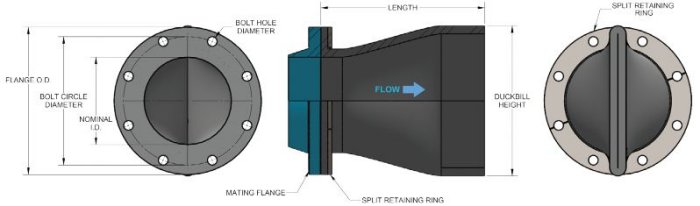

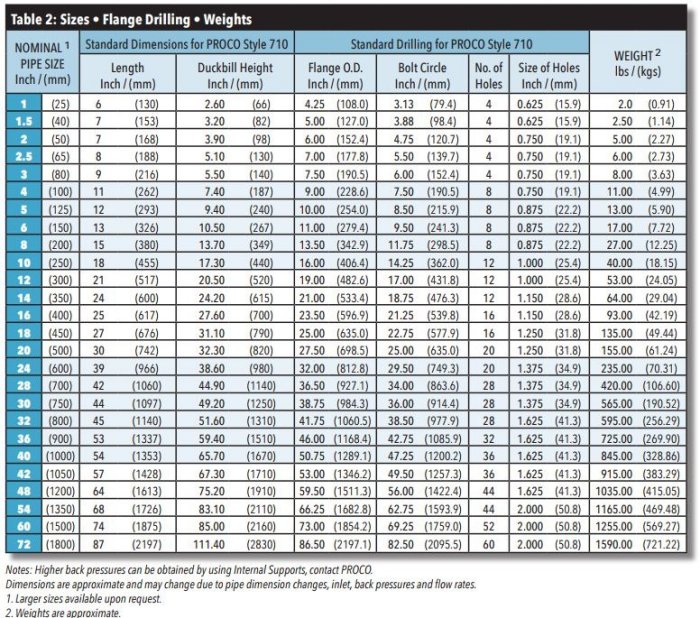

TheProco ProFlex Style 710 flanged duckbill check valve is designed to bolt directly to both existing flanges, as well as new installations. The flanges are drilled 150# standard, however other drilling standards are available upon request. The ProFlex Style 710 can be installed in either a vertical or horizontal application.

Some notable features of the Proco ProFlex Style 710 include:

- All-rubber construction to resist abrasive slurries

- Ultra-quiet operation, with no water hammer

- Unique design to prevent backflow

- Negligible maintenance and energy costs

- Will not warp or freeze

- Quick interchange with any flap type check valve

- Available in sizes from 1” to 96”

- Available with special ID to suit concrete pipe

The PROCO Series 700 “ProFlex” Rubber Check Valve is a cost effective way to control back pressures from sewage treaent plants, outfalls and tidal operations. They are a fully passive flow device requiring neither maintenance nor any outside sources of power or manual assistance to operate.

The PROCO Series 700 “ProFlex” Check valves are offered as direct replacements for ineffective and maintenance ridden flap type check valves, commonly known to seize, rust and bind in unwanted positions. Unlike flap type valves, the “ProFlex” rubber check valve will handle large obstructions without jamming or having swing gates binding open. Specify the PROCO Series 700 “ProFlex” rubber check valves to provide backflow protection from (1) Sewage slurries, (2) Outfalls to ocean fronts from heavy rainfall activity, (3) Prevention from land erosion due to back flow conditions, (4) Protection from saltwater to fresh water ponds and catch basins and numerous other water based applications. Our history in the manufacture of rubber piping products dates back to 1930. When an engineered solution is needed to solve a piping or backflow problem, call PROCO.

The PROCO Series 700 “ProFlexTM” Rubber Check valves are available in a Flanged (Style 710 or 720), Sleeved (Style 730 or 740), or Jacketed (Style 750). Inline orifice (style 770/780)

- Style 710: Flanged: Designed to bolt directly to existing flanges or new installations, flanges are drilled 150# standard. Other drilling standards are also available upon request. The style 710 can be installed in either vertical or horizontal application.

- Style 720: Flanged Inline: Designed to fit directly inside of an existing pipe. Supplied with a flat face rubber flange which allows installation between existing pipe flanges eliminating the requirement for a valve body. Other drilling standards are also available upon request.

- Style 730: Sleeve Type: Designed to easily slip over an existing pipe, is affixed to a pipe with heavy-duty Stainless Steel clamps. Can be installed in either vertical or horizontal application.

- Style 740: Slip In Inline: Designed to slip directly inside of an existing pipe. Supplied with a stainless steel expandable clamp to secure it in place.

- Style 750: Jacketed: Designed with a full metal enclosure which allows easy installation in existing piping systems. Utilizes the Style 710 as the check valve.

- Style 770/780: Designed with a metal or plastic orifice plate and a rubber disk , this valve is an ideal valve to provide high back pressure capability on clean water applications

- Style 790: Low Headloss In-Line: Designed as an all one piece constructed valve, the Style 790 is one of lowest headloss valves on the market. A passive flow device insuring no delamination.

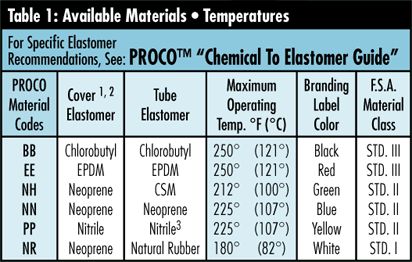

ELASTOMERS: All of the PROCO Series 700 “ProFlex” Rubber Check Valves are available in a various selection of elastomers including NSF/ANSI 61 certified material and back pressure capabilities to suit most applications.

The PROCO Series 700 “ProFlex” Rubber Check Valves will not freeze or deform and functions solely on the inlet and back pressure which will be present in each application.

Each valve is carefully constructed using the finest of engineered materials and some of the most experienced rubber technicians in the industry. All check valves are engineered in precise detail to ensure proper operation and will provide years of unhindered operation and trouble free service.

Benefits of the PROCO Series 700 ProFlex Rubber Check Valves:

- All rubber construction resists abrasive slurries

- Barnacle resistant Neoprene is standard construction, with NSF61 material available.

- Very quiet operation with no water hammer

- Its unique design prevents backflow

- Negligible maintenance and energy costs

- Will not warp or freeze

- Quick interchange with any flap type check valve

- Available in sizes 1”– 96”

- Available with special I.D to suit concrete pipe

The ProFlex 710 is a full port, concentric design Rubber Duckbill Check Valve. The ProFlex 710 Rubber Duckbill Check Valves can be supplied with many different flange drilling configurations, including square or rectangular flanges to suit problematic sluice gate or flap gate replacements.

The unique advantage to this valve is its very low 1”- 2” ( 25mm-50mm) cracking pressure and is often referred to as the lowest head loss valve in the industry.

All ProFlex 710 Rubber Duckbill Check Valves are supplied with 316ss retaining rings and can also be supplied with 304ss, Galvanized, Epoxy coated or FRP material if required.

The ProFlex 710 Rubber Duckbill Check Valves come standard with ANSI 125/150 flange drilling and can also be supplied with DIN, JIS, BS or AS flange patterns.

All ProFlex 710 Rubber Duckbill Check Valves are also available from inventory in a Standard Rated (SR) design up to 24in (600mm), and can also be custom manufactured to meet specific head and back pressures.

For higher pressure/vacuum requirements, the ProFlex 710 Rubber Duckbill Check Valves can also be manufactured using a unique Internal Vaccum Supports (IVS) design which is homogeneous to the inner reinforced layers of the valve allowing a full flow with no obstructions and yet providing excellent anti-inversion features.

NOTES:

- ProFlex is a trademark of PROCO Products, Inc.

- All products are reinforced with polyester tire cord.

- Check Valve “cover” can be coated with Hypalon on special order.

- Styles with Neoprene covers meet all requirements of U.S.C.G.

- NSF/ANSI Standard 61 certified materials available upon request.