- Home

- Companies

- Creaform - AMETEK, Inc

- Products

- Go!SCAN - Professional Portable 3D ...

Go!SCAN - Professional Portable 3D Scanner

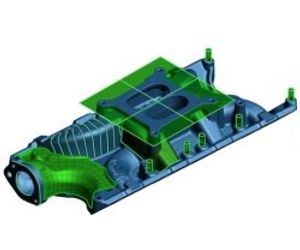

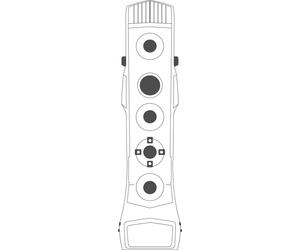

Go!SCAN 3D enables easiest 3D scanning experience, generating fast and reliable measurements for all your design and prototyping needs. Effortlessly capture the 3D shape and color of any object. Accuracy: up to 0.050 mm. Resolution: 0.100 mm.

When ease of use meets versatility and portability

The Go!SCAN 3D is our fastest, user-friendly handheld 3D scanner. A powerful tool during the product development phase, the Go!SCAN 3D quickly measures any complex surface making it possible to “get it right” the first time. With its seamless integration to your 3D modelling software and your product life cycle management workflow, it will greatly improve product development, foster innovation and shorten time to market.

Designed to scan any object without need for a set-up, it offers flawless texture and geometry acquisition as well as impressive details in a rich color palette. Just go…and scan!

- High level of details

- Accuracy up to 0.050 mm (0.0020 in)

- Color acquisition

- No set-up required

- Worldwide support

- Patented technology

The high resolution and level of details of the Go!SCAN 3D provides astounding scan quality. Featuring full support of color, it creates spectacular results!

- Reliable results

- Resolution of 0.100 mm

- High resolution for intricate details

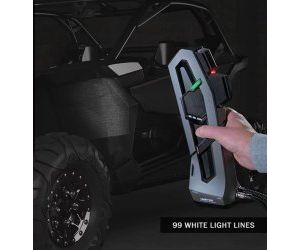

Everything about the Go!SCAN 3D has been considered to make your work more efficient. Its portability is second-to-none: take it anywhere you need!

- Lightweight

1.25 kg (2.7 lb) - Dynamic referencing

Both the object and scanner can be moved freely during scanning - Fits into a suitcase

Your work needs to be completed quickly? The Go!SCAN 3D is our fastest technology. Most objects can be scanned in mere minutes and quickly integrated into your preferred software, whether for reverse engineering, computer aided design or 3D printing sorfware.

- Instant mesh

Ready-to-use files - High measurement rate

Up to 1,500,000 measurements/s

99 white light scanning lines - Quick set-up

Up-and-running in less than 2 minutes

The Go!SCAN 3D is so user-friendly that anyone can begin scanning both small parts and large objects within minutes, even without prior experience. It is designed to perform without any part preparation; simply point and shoot! An instant preview is provided during scanning, showing what is left to capture in real-time.

- Plug and play

- Simple user interface and real-time mesh visualization

- Scan any object with a single device

- Positioning using geometry, color or targets

Looking for the ultimate portable metrology-grade 3D scanner for quality control or product development?

Our experts will find the perfect 3D measurement solution for you!

A brief look at technical specifications of this innovative technology that enables TRUaccuracy, TRUsimplicity, TRUportability, and speed for your product development applications.

- Accuracy

- Up to 0.050 mm (0.0020 in)

- Volumetric accuracy

- 0.050 mm + 0.150 mm/m (0.0020 in + 0.0018 in/ft)

- Resolution

- 0.100 mm (0.0039 in)

- Measurement Rate

- 1,500,000 measurements/s

- Part size range (recommended)

- 0.1–4 m (0.3–13 ft)

Innovating technology that provides TRUaccuracy™, TRUsimplicity™, TRUportability™ as well as real speed to your metrology-grade applications.

(1) Typical value for diameter measurement on a calibrated sphere artefact.

(2) Performance assessed with traceable length artefacts using positioning targets. Objects with sufficient geometry/color texture can enable this level of performance without positioning targets. Results are obtained using integrated photogrammetry with volumetric accuracy optimization.

(3) The volumetric accuracy of the system when using a MaxSHOT 3D cannot be superior to the default accuracy.

(4) Also compatible with all major metrology, CAD, and computer graphic software through mesh and point cloud import.

Our Centers are located all around the world and offer the following services* in different languages.

- Software and hardware Technical Support Helpline

- 3D scanner basic and advanced repair

- Equipment maintenance and tuning

- Loaner services

- 3D scanner component replacement

- Parts reselling

- Warranty renewal

* Services may vary depending on 3D metrology centers.

Creaform designs, manufactures and calibrates Go!SCAN 3D scanners with the highest quality management system according to internationally recognized standards ISO 9001.

We take pride in owning each step of the process, from beginning to finish. Each scanner is delivered with a personalized certification and fully documented test results.

World Class High Quality & 3D Precision Standard

At Creaform, product and service quality is our top priority. Being pioneers in portable 3D measurement, we are committed to developing innovative solutions that exceed our customer’s requirements. We are invested in continuously improving processes, setting new industry standards and ensuring the full satisfaction of our clientele.

CAD design

- 3D scan-to-CAD

- Reverse engineering {extracting design-intent)

- Packaging design

Requirements and specifications

- Competitive product analysis

- Measurement of product environment or connecting/Surrounding parts

- Measurement of existing parts for aftermarket or custom equipment

Concept design

- Clay model measurement/Reverse engineering

- Models and mock-ups measurement/Reverse engineering

- Styling and aesthetics

Replacement/Recycling

- Reverse engineering for developing replacement /Restoration parts

- Planning of complex assemblies disassembly/ Dismantling

Tooling design

- Reverse engineering of dies, molds, fixtures, jigs and patterns

- Update of CAD file to reflect as-built tooling measurements

- Tooling validation/Inspection

Assembly/Production

- Virtual assembly

- Tool/Robot path programming

- Part assessment before machining

Quality control

- First article inspection (FAI)

- Part-to-CAD inspection

- Supplier quality inspection

Concept prototyping

- Integration of prototype modifications into CAD file

- Form study, proof-of-concept prototypes

- Ergonomy prototypes

Documentation

- As-built documentation of parts/Tooling

- Marketing presentations. 3D training systems, serious gaming

- Digital archiving

Maintenance, repair and overhaul (MRO)

- Wear and tear analysis

- Custom repairs/Modification

- As-built documentation of parts/Tooling before maintenance

Prototyping

- Rapid prototyping/Manufacturing

- Integration of prototype modifications into CAD file

- Prototype inspection

Testing, simulation and analysis

- Finite element analysis (FEA)

- Interference analysis

- Deformation, geometry analysis