- Home

- Companies

- Yokogawa Electric Corporation

- Products

- Yokogawa - Model FA-M3 - Programmable ...

Yokogawa - Model FA-M3 -Programmable Logic Controller (PLC)

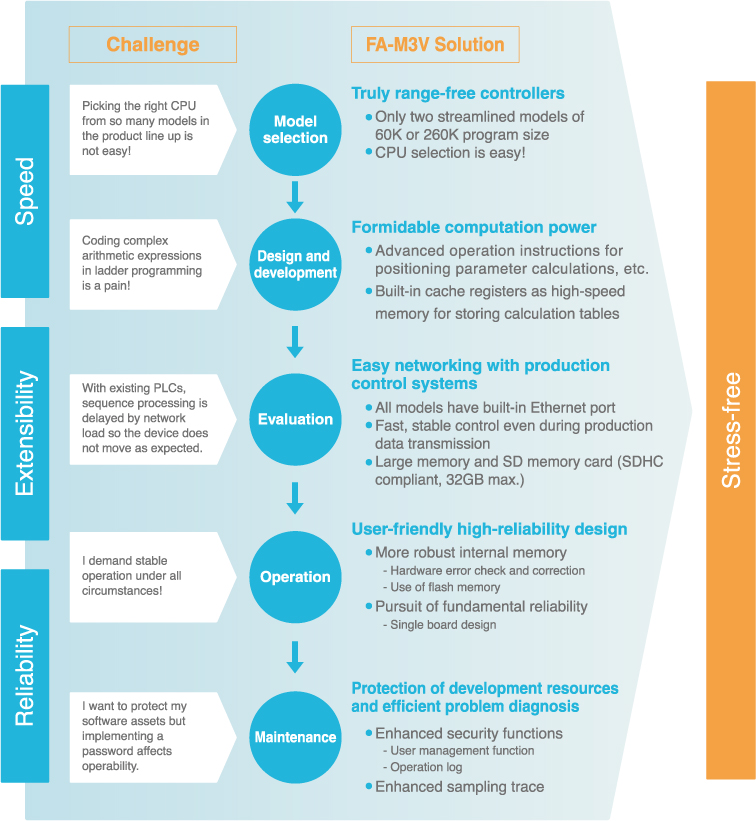

The FA-M3 is designed and best known for its speed so it`s only natural that the new series be named FA-M3V, where V stands for "Vitesse", which means speed in French. From day one, FA-M3 has relentlessly pursued higher speeds as the most effective means to solving customer challenges. Over time, this has evolved into the High Speed IPRS (Instruction, Processing, Response and Scan) design concept. Today, we have set a new record in this quadruple speed quest by creating the FA-M3V, which offers extensibility and reliability at incredible speed. FA-M3V, the leading edge controller for customers who will settle for nothing less than the world`s best.

High-precision calculation capability plus enhanced security with user management and operation log means even better reliability.

Featuring ultra high-speed, stable control, link functions and improved network performance, the FA-M3V controller is created by improving every aspect to deliver stable control at the highest speeds.

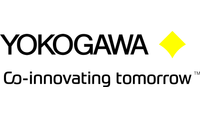

Stretching the "High-speed IPRS" Design Concept

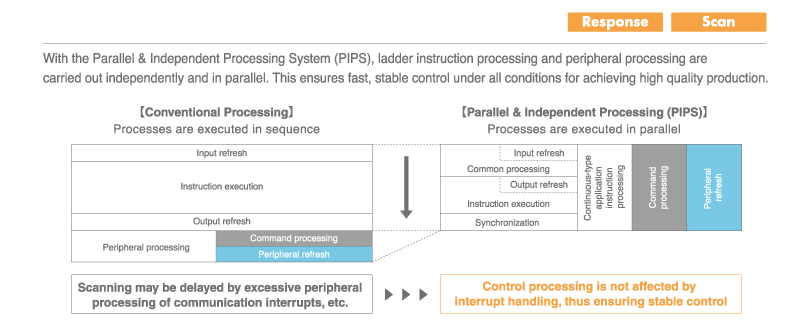

FA-M3V is the industry`s fastest PLC in terms of CPU scanning speed. This incredible speed is made possible by stretching the High-speed IPRS (Instruction, Processing, Response and Scanning) design concept of the FA-M3 family of controllers and harnessing two Yokogawa core technologies, namely, the Vitesse engine and the parallel instruction processing system (PIPS).

Quadruple speed quest based on the High-speed IPRS design concept

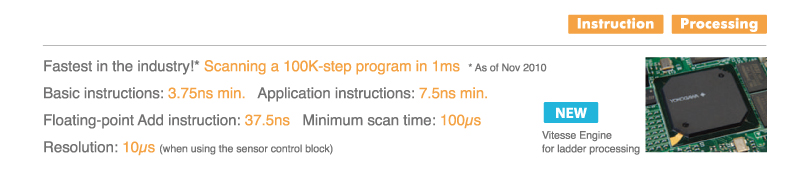

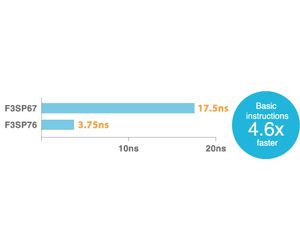

High-speed Instructions -Unrivalled High-speed Processing

3.75ns for basic instructions, 7.5ns for application instructions and 37.5ns for floating-point add instruction

Faster processing of basic instructions enables reduced tact time using faster equipment, supports high-speed networking, enhances operability, as well as supports fault diagnosis and other advanced functions. In addition, faster application instructions widen utility to more applications. Floating-point addition instructions can also be speeded up to meet the requirements of high-precision applications.

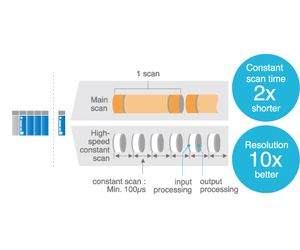

Sensor control function enables fast, constant scan from 100μs (10μs resolution when using SCB)

FA-M3V`s sensor control function allows input, computation and output of one program block to be executed at constant intervals as short as 100μs, independently of the main scan, which may have a longer scan time due to advanced functionality of external devices.

The number of PLC units can be reduced since two ladder programs can be executed by one CPU module.

Interrupt response time of 85μs and digital filter from 0ms

With input response time of 85μs for interrupts from DC input modules, the FA-M3V can immediately respond to changes in inputs, enabling instantaneous high-speed control. Fast response (circuit delay 100μs min.) is achieved by focusing on total response time (input program execution (processing) output) and allowing variable time constants to be set to zero. Moreover, input response time of 10μs can be achieved with the use of a high-speed contact input module (F3XD16-3H).

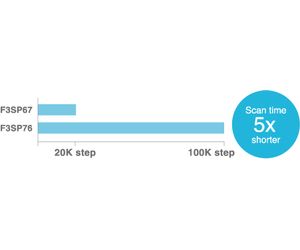

Scanning a 100K step ladder program in 1ms

The incredible speed of the FA-M3V of processing 100K ladder program steps within 1ms is achieved by analyzing its internal processes and striving for speed in every aspect. This translates into five times faster scanning for advanced device applications.

* The quoted scan time is achievable under certain conditions. Actual scan time may vary with program processing and system configuration.

Over and above fast, stable control, the FA-M3V delivers extended functionalities, including diverse network support, large file transfer and "PC-less" maintenance for improved productivity.

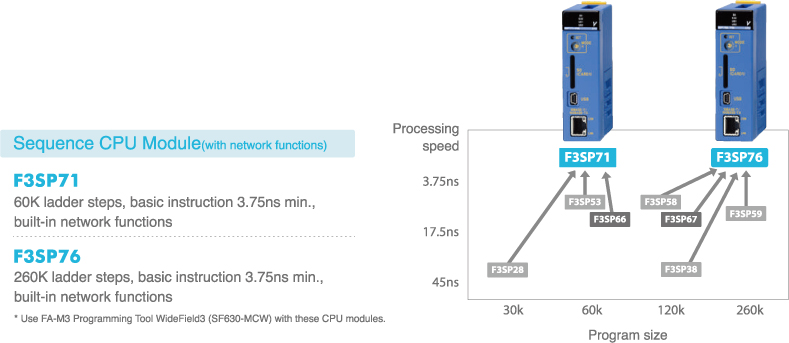

The FA-M3 family of controllers is consolidated into two new CPU models of 60K-step and 260K-step program size so picking your ideal CPU is easy!

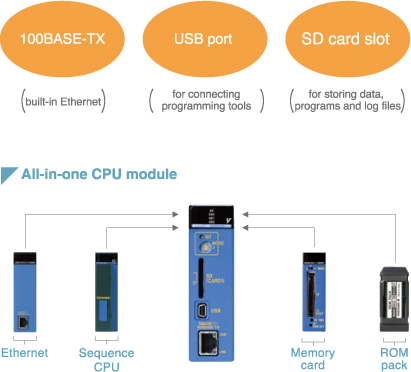

Built-in Ethernet port for easy integration with manufacturing systems

Faster Ethernet Communication Processing

The built-in Ethernet port enables fast, stable communication. With a variety of functions condensed into an all-in-one CPU module, the FA-M3V offers cost advantages, a smaller footprint and networking that will not degrade control processing performance.

Fast communication response is achieved without compromising stable control.

Scaling up to process large production data is simple.

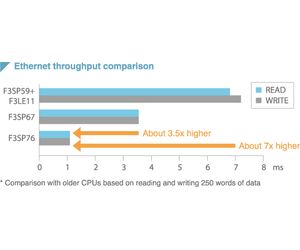

- Much higher Ethernet throughput

- Large memory and SD memory card (SDHC compliant 32GB max.)

- Cache registers (1MB max.)

- Modbus/TCP Slave (server) function

Higher precision with more data digits, better reliability with built-in ECC

High-reliability Design for Reducing Failure Rate

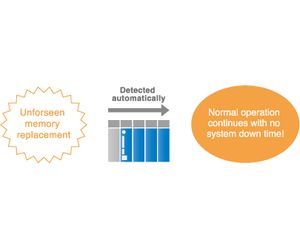

SRAM Hardware Error Check and Correction (ECC)

- Hardware error check and correction (ECC) for the program execution area (within ASIC and external SRAM)

- ECC does not impair performance

- Improved reliability through patrol check* (only for backup SRAM)

Use of Flash Memory

- Flash memory is used for storing programs. This minimizes the impact of memory data loss at power off.

Pursuit of Fundamental Reliability -Single board design-

- Reducing the number of components fundamentally reduces the sources of failures.

High-precision Calculations

Operations preserving 32-bit significant digits -64-bit integer arithmetic-

- No need to convert all the way to floating point data for calculation

Double-precision floating point operations

- Built-in floating-point unit (FPU) for floating-point operations

- No precision loss even if converted to floating-point data for calculations

Safeguards important customer assets by preventing unauthorized copying and keeping an operation log.

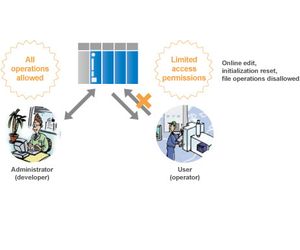

User management function

Appropriate access permissions can be defined for administrator, service and user personnel so that better security and work efficiency can be achieved concurrently.

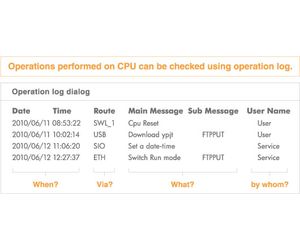

The operation log function keeps a historical log of operations performed on the CPU module. With the user authentication function, the user name of the person performing an operation can also be recorded.

New, useful functional enhancements based on user requirements

Improving program development efficiency is a common concern of all PLCs. The latest FA-M3 Programming Tool WideField3 is designed to harness the incredible power and speed of the FA-M3V. Its new features include balloon comment and monitor for more convenient programming, as well as the cross reference and script functions for more efficient programming. Besides engineering support function is added for efficient debugging.

Great performance for debugging and troubleshooting

The Virtual-M3 is a simulation software which runs ladder sequences on a PC and debugs programs without any real machine. The I/O module sumulation function, link function with HMI, step operation function, and link function with Live Logic Analyzer drastically reduce the debugging time.

User-friendly engineering feature to leapfrog your debugging

The live logic analyzer stores the status and contents of devices designated for sampling in the trace buffer memory, as the sampling trace tool does, and immediately displays the trace results.

Trace results can be displayed in scan chart format while ladder program running high speed application concurrently.

Upgraded trace function by high-speed communication

- Up to 96 data points (64 relays and 32 registers) can be traced concurrently.

Large sampling capacity up to 1M samples per channel - Even advanced-function I/O devices can be traced.J53

- Once started, trace result can be displayed anytime, allowing concurrent program debugging even during tracing.

Traces equal to actual production performance

- Minimized trace execution impact on the CPU scan.

- The trace runs with minimal impact on the CPU scan and thus reflects actual production performance.

- USB and Ethernet peripheral processing run in parallel independently without affecting the CPU scan.

High degree of usability by powerful HMI

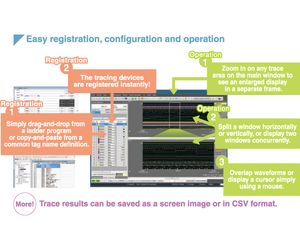

- Easy registration, configuration and operation.

- User marker enables pin-point search of massive trace data.

- Zoom in on any trace area on the main window, split a window horizontally or vertically.

Advanced analysis environment with oscilloscope-like view

The sampling trace function enables efficient debugging and timely troubleshooting.

The new version adds improved readability to advanced, flexible configuration, and introduces oscilloscope-like convenience functions including inter-point analysis, range zooming and filter configuration.

Various types of trace mode

- Single trace

This mode performs a sampling trace only once. - Multiple trace

This mode performs multiple sampling traces successively.

After one cycle of sampling is complete, the sampling trace functions output results to files and then automatically wait for the trigger to occur. Therefore, you can successively sample data 100 times max. - Endless trace

The single trace mode includes the method of continuing sampling until a user cancels the sampling trace if "no end conditions" is specified (endless trace), in addition to the method of ending sampling automatically if a trace end condition is met.

Tool-less trace

Tool-less trace function enables to store the result of tracing data without using sampling trace tool.

You can execute the trace with the card batch by using an SD card and with virtual directory commands. You can obtain sampling trace results via the SD card or through FTP file transfer.

After the results are stored in a personal computer, you can view them in WideField3.

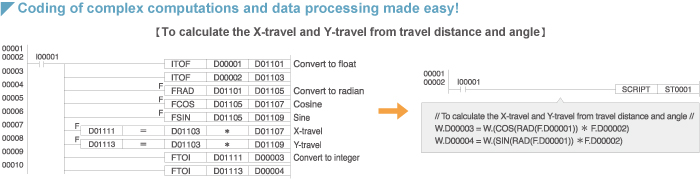

Complex calculation processing made easy!

Computations and text manipulations can be programmed using script code, which is converted automatically into ladder code before execution. Moreover, used devices can be monitored within script code for efficient debugging, and mnemonics can be entered in script code for even more powerful programming!

for all process challenges from development through maintenance.

Starting right from CPU model selection all-the-way to maintenance after commissioning, the FA-M3V promises a stress-free experience by enabling development according to design and reducing development effort from ladder program design to engineering.