Scientific and manufacturing Firm (SMF) `Prodecologia`

- Home

- Companies

- Scientific and manufacturing Firm (SMF) ...

- Products

- SMF - Model SH - Pulley Magnetic ...

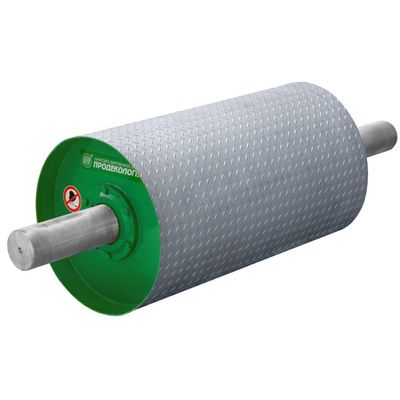

SMF - Model SH -Pulley Magnetic Separator

Designed for extraction of ferro magnetic impurities crumbling that are moved by the belt-type from materials conveyor. Installed as drive and non-drive drums in belt-type conveyors.

Most popular related searches

magnetic separation pulley

magnetic pulley separator

magnetic separation

carbon black production

carbon black product

domestic waste recycling

bulk materials transport

conveyor belt

belt conveyor

recycling industry

Designed for extraction ferromagnetic impurities from the bulk material transported by the conveyor belt.

Sapplied to enterprises of the following industries:

- heat network

- fuel industry

- ferrous metallurgy

- non-ferrous metallurgy

- recycling of industrial and domestic wastes.

- Building ceramics industry

- Carbon black production

- Cement industry

- Chemical Industry

- Coal mining industry

- Compound feed industry

- Fat-and-oil industry

- Ferrous metal production

- Flour, cereals and feed industry

- Mining and beneficiation of ore raw materials for ferrous metallurgy

- Municipal engineering

- Non-metallic building materials industry

- Peat industry

- Porcelain industry

- Power engineering

- Processing (recycling) of cullet

- Processing of plastic waste

- Production of ferroalloys

- Recycling of household appliances

- Recycling of worn tires

- Recycling of worn tires

- Refractory processing

- Salt industry

- Solid household waste recycling

- Starch industry

- Sugar industry

- Tea industry

- Textile industry

- Tire production

- Titanium-magnesium industry

- Tobacco industry

- Wall materials industry

- WEEE and PCB`s recycling

- WEEE recycling

- Woodworking industry

Passing on the pulley surface and being subjected to the magnetic field, ferro-magnetic impurities of the product are attracted to the surface of the pulley and remain on the conveyor belt until the time of their exit from the effective area of the magnetic field. The purified product is fed to the production by a natural path, and ferromagnetic impurities fall down into a special container.

- Designed both as the driving and non-driving drum for belt conveyors.

- Designed with different levels of magnetic force and magnetic induction according to customer requirements.

- The height of the layer of material to be separated is within 40 to 180 mm.

- Configuration of the magnetic field can be radial or axial for maximum separation efficiency.

- Designed drums of 6 deameters: 250, 320, 400, 500, 630, 800 mm, with length of pulley within 400 to 1400 mm.

- Designed with rod, bearings and drive is available.