- Home

- Companies

- Apoaqua Group

- Products

- Apoaqua - Model ApoPar-ZTO - Pulp Screw ...

Apoaqua - Model ApoPar-ZTO -Pulp Screw Press Machine

With the rapid development of the paper industry, the demand for paper and cardboard has increased dramatically. This makes the supply of paper fiber an urgent problem. In order to make up for the serious shortage of wood raw materials, the recycling of waste paper has attracted people’s attention.

The recycling of waste paper has improved the recycling rate of existing waste paper. And it also increases the proportion of secondary fibers in the structure of papermaking raw materials. Compared with using virgin resources, recycling waste paper reduces the consumption of natural fiber raw materials. Save 50% of water, 60%-70% of energy, and save about 21% of construction investment. Therefore, waste paper recycling has become one of the methods actively adopted by many paper manufacturers in the development of raw materials.

Source of deinking wastewater

Waste paper is used for pulping and papermaking. Wastewater mainly comes from the deinking and beating of waste paper and the purification and screening of pulp. The amount of wastewater is very large. Generally, the amount of wastewater is more than 100 tons for just one ton of deinked pulp. Coupled with the wastewater produced by beating and purifying the wet end of the Japanese paper machine, the amount of wastewater is even greater.

In addition, pollution indicators such as ink, SS, COD, and BOD (biochemical oxygen demand) in wastewater are relatively high. These pollution indicators greatly exceed the national wastewater discharge standards for the papermaking industry. And when the BOD/COD in the deinking wastewater is

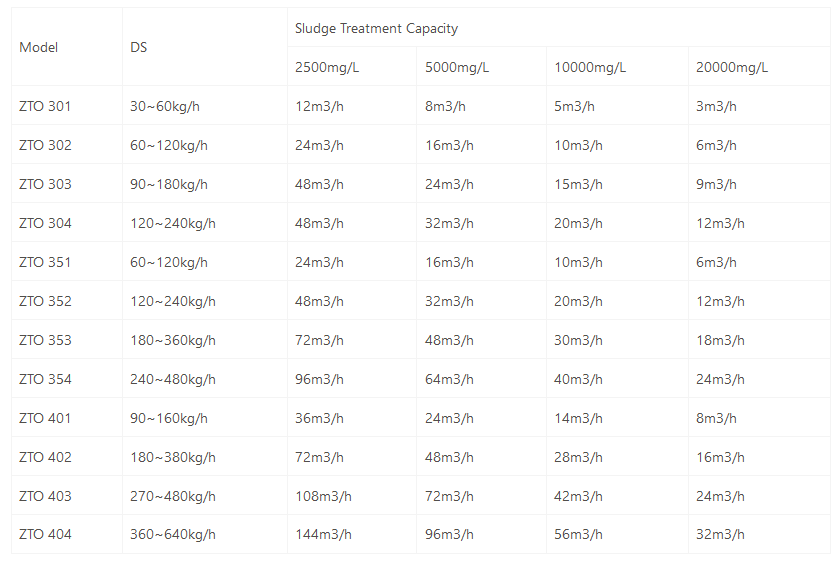

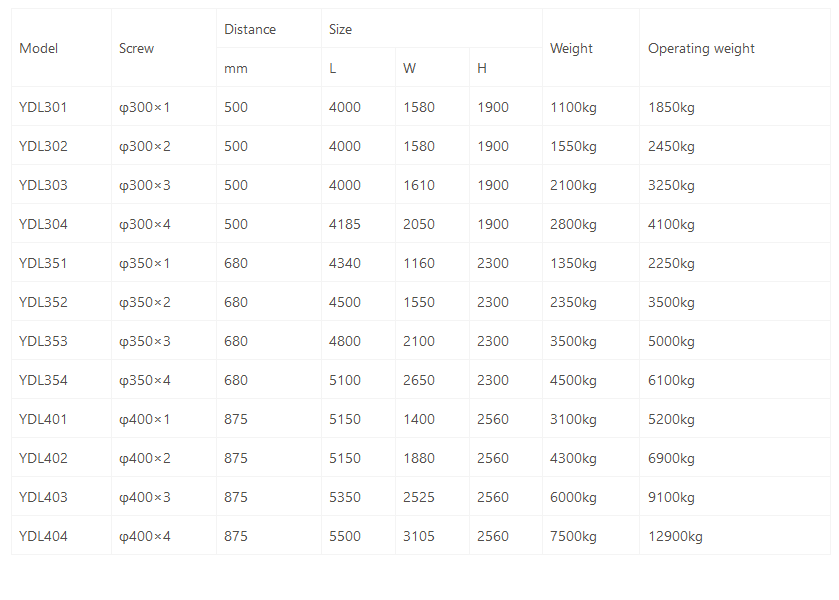

In the entire processing process, ApoPar-ZTO pulp screw press machine plays a huge role.

How to dewater paper mill deinking sludge?

- The wastewater after biochemical treatment in the aeration tank enters the auxiliary flow sedimentation tank.

- The muddy water is separated in the auxiliary flow sedimentation tank, and the effluent is adsorbed through the filter tower to filter out a small amount of ink.

- Finally, the effluent reaches the discharge standard and the sludge is discharged to the sludge concentration tank.

- The sludge in the sludge concentration tank is concentrated and settled, and the sludge is sent to the ApoPar-ZTO pulp screw press machine for dehydration.

- The sewage collection tank and sludge dewatering machine are used to dewatering and transport the sludge. The filtered water is returned to the recycling tank for further treatment.