- Home

- Companies

- SBM Ultrafine Powder Technology Co., ...

- Products

- SBM - Model DMC - Pulse Bag Filter

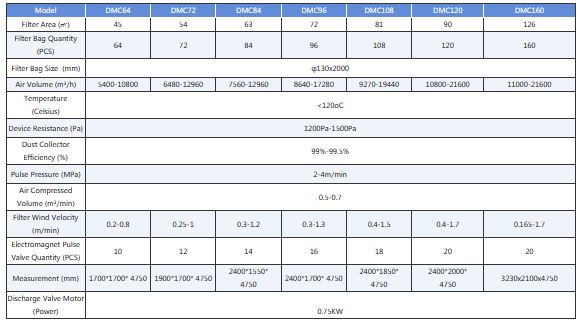

SBM - Model DMC -Pulse Bag Filter

The pulse bag filter is a dry filter device. It is suitable for capturing fine, dry, non-fibrous dust. The filter bag is made of woven filter cloth or non-woven felt, and the dust-containing gas is filtered by the filtering effect of the fiber fabric. When the dust-containing gas enters the bag filter, the dust with large particles and heavy specificity will be affected by gravity. The effect settles down and falls into the ash hopper. When the gas containing finer dust passes through the filter material, the dust is blocked, so that the gas is purified.

- Capacity: 99%-99.5%

- Max feeding size: 126?

Applicable materials: DMC pulse bag filter is suitable for capturing fine, dry, non-fibrous dust.

Product features: High dust removal efficiency

DMC pulse bag fiter, designed by us on the basis of absorbing many advantages of the same products, adopts advanced pulse blow technology.

DMC pulse bag fiter enables the machine completely clear the dust, low resistance. The qualified spare parts ensure the high-efficiency of bag filter.

It also have advantages of full automation, high-efficiency, easy maintenance.

It is not only suitable for collection of various powders, also can be used for dust purification of various crushing and screening equipment.

- High-fficiency. This pulse bag flter can be used to purity dusty gas with particle diameter more than 0.1μm.

- Collection efficiency can reach more than 99.5% in general, stable and reliable performance, easy operation.

- Strong adaptability. This pulse bag flter can capture various properties dust, and the collection fficiency isn`t affected by dust or resistance properties.

- Pulse bag filter mainly consists of upper box, middle box, lower box (hopper), dust cleaning system and discharging system.

- After the dusty gas gets into the upper box, the flow surface broaden suddenly, part of coarse particles fall down into the hopper by gravity, air flow distribution and inertial force.

- Fine and low-density dust enter dust chamber and cling to the surface of the filter bags.

- At the same time, PLC controls the startup of pulse valve, compressed air flock into filter bags, which makes filter bags expanded and vibrated, and then the fine powders cling to the surface of flter bags fall down into hopper and discharged on the discharge valve.

- At last, filtered clean air will be emitted from exhaust pipe.