Koras GmbH

Puras - Fully-Automatic Gold Refining System

FromKoras GmbH

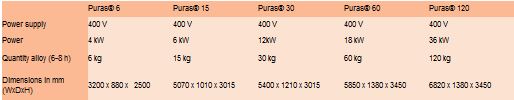

The first fully-automatic gold refining system with integrated nitric and hydrochloric acid recovery. The new Puras gold refining system from Koras® is able to refine all types of precious metal alloys in a fully automatic process without the release of acidic gases and with the recovery of nitric and hydrochloric acid. The system consists of glass reactors with a heating mantle with stirrer, gold precipitation container, and special fume scrubbers for NOx and Cl2 gases. These special fume scrubbers can be used to recover nitric acid (up to 50%) from NOx gases and hydrochloric acids (up to 30%) from HCl /Cl2 to enable reuse for the dissolving process. The complete fully automatic process guiding and monitoring is made using a touch display.

Most popular related searches

gold refining system

gold refining

hydrochloric acid

fume scrubber

hydrochloric acid recovery

precious metals refining

acid gas

exhaust fume

fume exhaust

exhaust emissions

- Reduction of the volumes of chemicals used

- Higher refining efficiency, up to 20% silver content is possible

- Reduction of required personnel through fully automatic program control

- No emissions of gases; a standard fume scrubber is not necessary

- 100% recovery of nitric acid (up to 50%) and hydrochloric acid (up to 30%) from the acidic exhaust fumes

- Exhaust emission values of NOx; HCL and CL2 are below the allowed limit values for Europe, China, etc.

- 100% fully automatic program control

- Process guiding and monitoring can be made using a notebook or mobile phone app