- Home

- Companies

- Puroxi Pure Water Global Inc.

- Products

- Puroxi AquiSense - UV-C LED Ultraviolet ...

Puroxi AquiSense - UV-C LED Ultraviolet Technologies

Puroxi has recently learnt allot about UV-C Led technologies. AquiSense is the world’s largest supplier of UV-C Led. AquiSense also have the best products on the market today. As you know we do not carry any products we cannot stand behind. Our reputation is more important than making the sale.

AquiSense is passionate about developing solutions that solve real-world problems in water, air, and surface UV-C LED disinfection applications.

Technology for homes, hospitals, airplanes, and even astronauts.

This will provide reliable, lower cost water to millions in remote communities.

They only work with leading UV-C LED manufacturers to evaluate their devices. Using a combination of patented technology and in-depth know-how, we integrate only the best LED devices into our products.

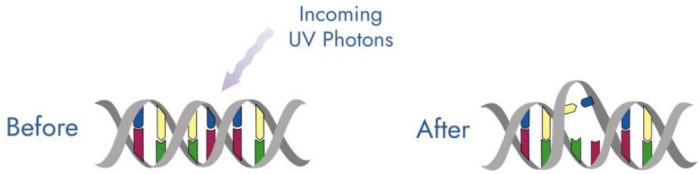

UV-C LED disinfection is “NEW ADVANCED” technology that uses light to damage the DNA of pathogens. This technology offers a variety of new benefits when compared to conventional UV purification. Similar to how visible LEDs effected the display market, they believe UV-C LEDs will have a lasting effect on how we disinfect water, surfaces and air. UV-C presents an innovative solution for providing clean and effective water purification.

But just how effective is this relatively new technology and can it provide the solutions we need now and for the future?

We will answer all your questions as you dive into the information about UV-C Led Technology.

Sakshi I will be doing subpages. After the dots like at the top here is a subpage this is Subpage 1.

UV (ultraviolet) light is a type of radiation that can be found in the electromagnetic spectrum and is measured in Nanometers (nm). Invisible to the human eye, UV is an effective disinfectant due to the density of its wavelength.

There are four ranges to UV light – UV-A, UV-B, UV-C and Vacuum-UV:

- UV-A – otherwise known as black light, it has the longest wavelength, ranging between 315nm to 400nm.

- UV-B – known as the medium wavelength, it ranges between 280nm and 315nm.

- UV-C – the shortest wavelength, it ranges between 200nm and 280nm.

UV-C is germicidal, meaning it can be used effectively as a disinfectant to kill microorganisms, such as bacteria and viruses.

When the DNA of microorganisms absorbs UV light, it stops them from being able to reproduce and duplicate, thereby preventing their growth.

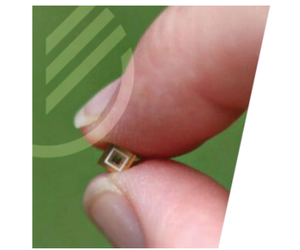

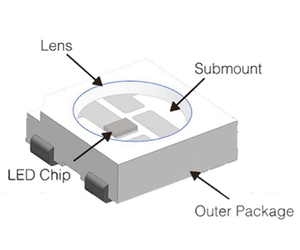

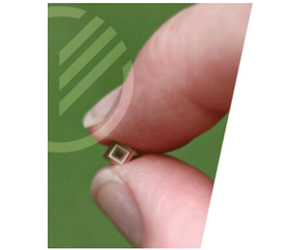

Light-emitting diodes (LEDs) are semiconductor devices that are made up of multiple layers of substrate materials. They can be designed so that a wavelength can be inputted and emit photons in the UV-C range that can be used to stop the replication of bacteria.

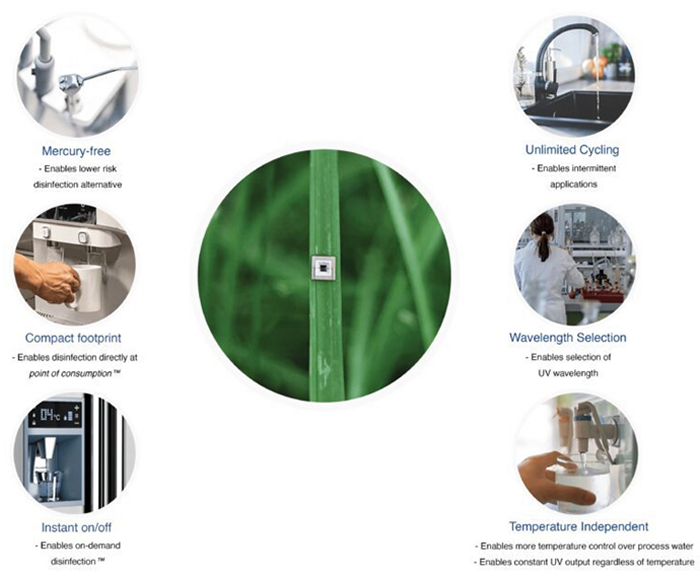

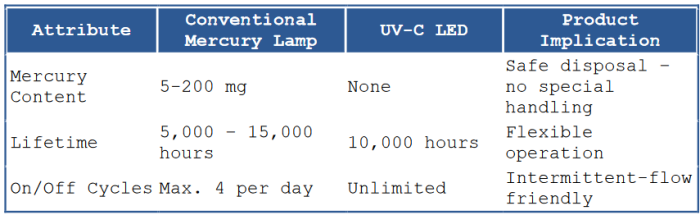

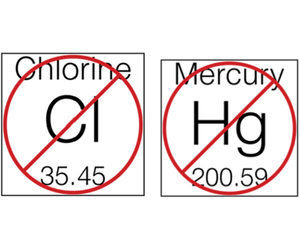

UV-C LEDs perform the same functions of conventional mercury-vapor lamps but have many benefits in comparison.

- Environmentally friendly – conventional UV lamps use heavy metals that are difficult to handle and cost a great deal to dispose of safely.

- Small design footprint – LEDs are much more compact compared to their mercury-vapor counterpart, meaning they can be integrated easily into new innovative designs.

- Instant-on/off – UV-C LEDs work instantly, so there is no need for a warm-up time that is a common constraint of mercury-vapor lamps.

- Unlimited cycling – on/off cycles do not impact the life of the LEDs, meaning there is an unlimited scope for lamp cycling.

- Temperature independent – LEDs can emit photons from a different surface as their heat emissions. They can be designed so that if UV-C LEDs are being used in water purification, they will not transfer heat into the water.

- Wavelength selection – One of the greatest benefits of UV-C LEDs is that users can configure them to choose a specific wavelength that is best suited for maximum absorption of light for the chosen microorganism.

Different types of UV-C disinfection can work depending on the scale of the solution being implemented. However, the principles of how UV-C disinfection works remain the same.

An LED produces a pre-selected wavelength from a small amount of electricity. The LED then emits UV-C photons through the water that penetrate the cells and damage the nucleic acid in the microorganism DNA.

As these cells cannot replicate, it renders the harmful microorganism inactive. As a result, UV-C LEDs allow for highintensity radiation to kill the bacteria in seconds, and its effectiveness is measured in LOGs.

Ultraviolet disinfection technology has been the star performer in water and air treatment over the past two decades, due in part to its ability to provide treatment without the use of harmful chemicals.

UV represents wavelengths that fall between visible light and x-ray on the electromagnetic spectrum. The UV range can be further divided into UV-A, UV-B, UV-C, and Vacuum-UV. The UV-C portion represents wavelengths from 200 nm - 280 nm, the wavelength used in our LED disinfection products.

UV-C photons penetrate cells and damage the nucleic acid, rendering them incapable of reproduction, or microbiologically inactive. This process occurs in nature; the sun emits UV rays that perform this way.

AquiSense Technologies, uses Light Emitting Diodes to generate high levels of UV-C photons.

The rays are directed at viruses, bacteria and other pathogens within water and air, or on surfaces to render those pathogens harmless in seconds.

Applications of UV-C LEDs

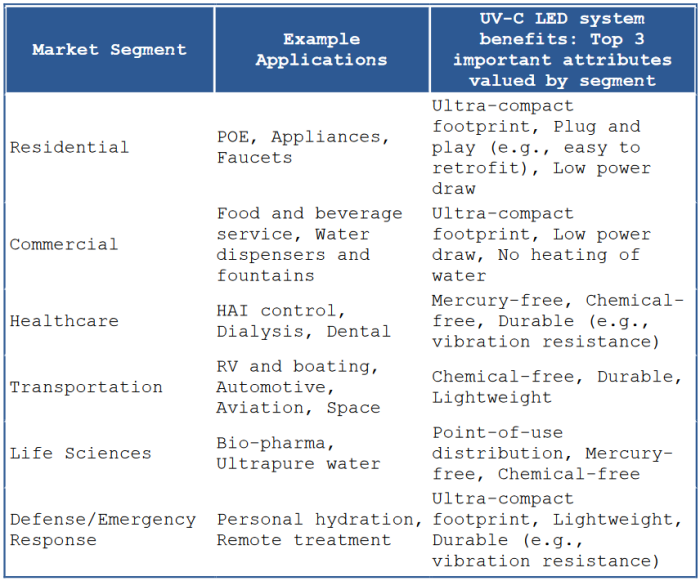

There are many applications where UV-C LEDs are being tested to see if they can become a solution to not just current disinfection challenges but our future ones too.

Drinking water disinfection, water purification, and treatment are where the technology is gaining traction as the solution is chemical-free, has no risk of creating harmful by-products, is an effective pathogen inactivation, and is very low maintenance.

As well as water, UV-C LEDs are offering disinfection for both air and surfaces. UV-C LED air purifiers for HAVC (heating, ventilation, and air conditioning) are being used increasingly in the commercial landscape.

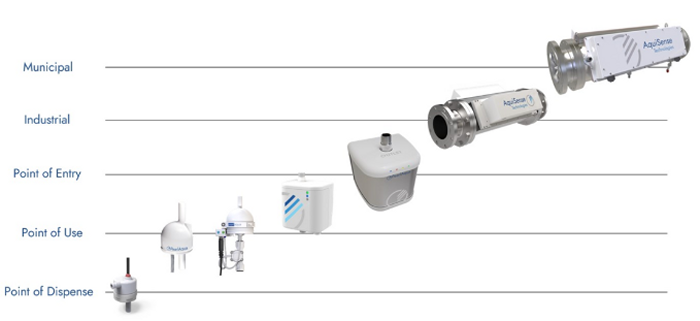

There are numerous applications, from residential to commercial, healthcare, transport, life sciences, defence, and emergency response where UV-C LEDs are finding new uses:

In much the same way that LEDs have revolutionized the display and lighting industries, UV-C LED technology is set to provide new, improved, and expanded solutions in both air and water treatment. Dual barrier, post-filtration protection is now available where mercury-based systems could not previously have been conceivably used.

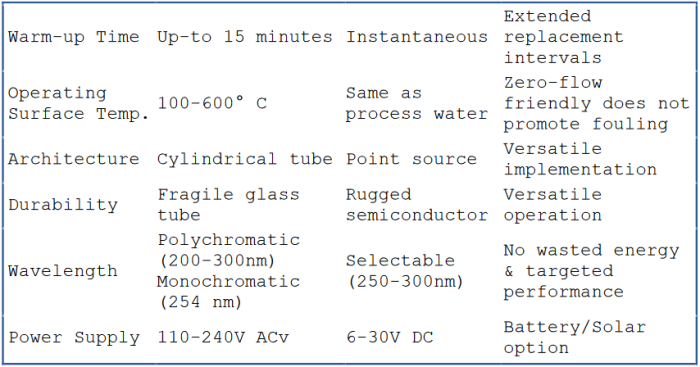

LEDs produce a selected wavelength from a small amount electricity- Depending on the composition of the LED it can produce anywhere from infrared, visible, and now UV-C wavelengths.

The side view of the LED shows that as power passes through the LED layers, it activates the desired wavelength.

The LED is then packaged to allow for electrical connection, thermal management, and physical protection. This helps maintain efficiency for the LED output and lamp life.

These LEDs can then be integrated into various systems to treat water, air, and surfaces. These systems also work with the LED packaging to disperse heat and improve efficiency of the disinfection process.

UV-C LED technology is now being used for water dispensing and water-cooling applications and requires expertise, experience, and significant engineering knowledge to integrate this technology.

To date, there have been three types of disinfection system concepts for integrating UV-C LED systems.

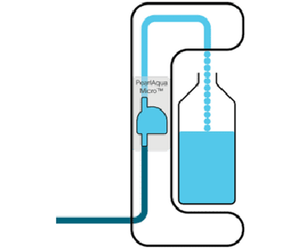

Inlet Disinfection System

For pre-existing water systems, the disinfection process is often left outside of the device, which can leave an opening for bacteria to grow at any point in the system. In the inlet model, the UV-C LED is easy to replace and will last considerably longer than its mercury-vapor counterpart.

While there is no need to redesign existing systems, the trade-off of having an inlet system is that the components are visible and are therefore more susceptible to damage.

In Process Disinfection

In this configuration, UV-C LEDs are integrated into the current system. This set up has several benefits: the UV-C LED component is protected, the amount of contamination between unit and dispenser is significantly reduced, and this model makes use of the compact nature of the LEDs.

The one major drawback to the in-process disinfection model is that it is susceptible to retrograde contamination and bacteria growth up the pipeline.

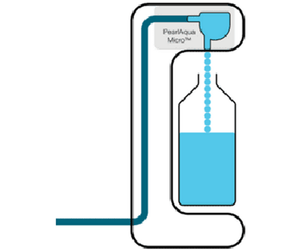

Point of Consumption Disinfection

This system offers the greatest amount of protection by taking advantage of the full attributes of UV-C LED technology-Installed at the point of consumption, the system features an instant on/off switch.

Point of Consumption disinfectant systems have the most benefits, but due to the complexity and expense of the new system, they are the most complicated to install and design.

They can become contaminated by an external source, in which the bacteria can grow through the pipe into the system. This can be prevented by the regular cycling of the system.

One area where UV-C LEDs are proving to be successful is in the disinfection of drinking water.

UV-C LEDs are being to disinfect drinking water at various points in the treatment cycle, from source to consumption. It can take a few seconds for the water to become clean in a UV-C model, and the new technology allows for LEDs to be placed at a different point to ensure decontamination.

It works initially when a water reservoir is exposed to a number of high-powered LEDs that disinfect the water. They emit powerful UV-C photons in the range of 200 - 280nm that pass through the water, stopping the bacteria in the water from being able to reproduce.

Many newer systems have taken advantage of the compact size of the LEDs and can disinfect at the end stage of the drinking water journey - ensuring complete disinfection.

LOG reduction is used to measure how thoroughly a decontamination process reduces the amount of contamination.

For example, 1-log reduction means the number of bacteria is 10 times smaller, 2-log equals 100 times smaller, 3-log equals 1,000, and so on.

To put this into perspective, if a surface had 100,000 microbes present, it would take 5-log reduction to bring the number of microorganisms down to just one.

A recent paper released in Science of the Total Environment journal looked at various microbial disinfection methods for UV-LED water treatment systems. It found that UV-C LEDs were effective in the inactivation efficiency and energy consumption of UV-LEDs for pathogens at various wavelengths.

As UV-C LEDs can select various wavelengths to target specific microorganism present in infected water and deactivate them, different pathogens and bacteria stop replicating when they have been exposed to different wavelengths.

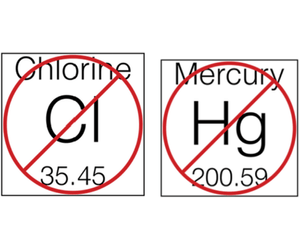

A 1 though UV d i s i n feet i.on i s genera 1 1 y cons i do rod sa f or than chemical disinfection, all conventional UV lamps typically use between 5-200 mg of mercury per lamp.

These UV lamps require routine replacement and are susceptible to breakage during transportation, handling, and operation. UV LEDs are mercury-free and provide a safer alternative. This has created new markets for UV disinfection where traditional UV lamps containing mercury were banned for safety reasons (e.g., medical devices, space).

Conventional UV lamps hold their mercury either in a liquid form (more common in medium pressure lamps) or an amalgam (more common in low pressure, high output lamps). Amalgam UV lamps contain solid "spots" which consist of an alloy of mercury and another element, such as indium or gallium. Liquid mercury lamps have the potential to be hazardous both during operation and when the lamp is off. While the lamp is operating the mercury vaporizes; if the lamp is broken, mercury vapor is easily dissolved into the treated product. Accidents and improper procedures increase the risk of exposure to people and the local environment.

UV-C LEDs do contain small amounts of elements such as the metals gallium and magnesium and the metalloids silicon and boron (although boron is not predominantly used). These metals and or metalloids are bound within a stable crystal structure and cannot leach into the environment.

The inherent stable crystal structure of an LED ensures that UV-C LEDs are very robust to mechanical or environmental shock.

The Minamata Convention on Mercury was initiated by the United Nations Environmental Programme (UNEP) to protect human health and the environment from anthropogenic emissions and releases of mercury. The UNEP has set the goal for mercury to be phased out of production by the year 2020.

Although the Minamata Convention does not specifically prohibit the manufacture and sale of UV mercury-vapor lamps, it will provide a generally positive influence for the more widespread adoption of alternative technologies. Potential responses may include the following actions:

- Corporations that use UV systems in products or manufacturing processes (e.g., white goods, beverage, microelectronics, life sciences) may implement best practices by selecting an LED option by the influence of the Minamata Convention, not by enforcement.

- Original Equipment Manufacturers that currently employ conventional mercury lamps may see a conflict with the use of mercury-based products to their own environmental policies and, based on Minamata regulations, might start a transition to develop new products using mercury-free light sources.

- Municipalities may also follow suit in adopting UV-C LEDs, although it is more likely that they will require more time to adopt the new technology.

- There will always be a percentage of people that will look for “eco-friendly” product options. As the Minamata Convention raises awareness of the effects of mercury, it inherently affects the use of mercury-based lamps without banning the sale or manufacturing of these lamps.

- Regulators will likely have a slow transition from mercury to UV-C LED lamps. Regulators will always look for viable alternatives to mercury, as it is their mandate to steer technology to the most holistically sound solution.

Three Distinct Platforms:

Water Treatment

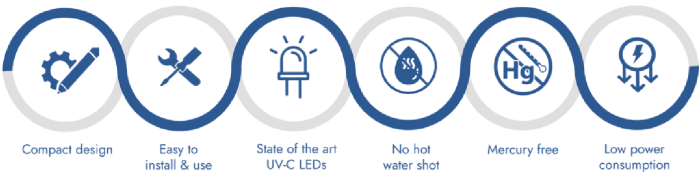

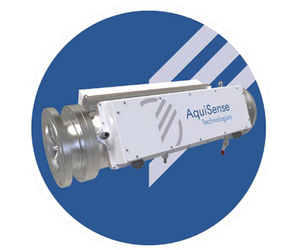

We introduced the first UV-C LED product designed for water disinfection. Find out more about how the PearlAqua range integrates state-of-the-art LEDs into unique and compact designs. Introduced in 2012, PearlAqua is the world’s first UV-C LED product designed for water disinfection. This system integrates state-of-the-art LEDs into a unique and compact design, without the use of chemicals or mercury-based lamps. LEDs also allow for instant full-intensity power, unlimited cycling, remote start/stop, and no heat transfer into the process fluid.

PearlAqua Micro is simply the world`s smallest UV disinfection system, ideal for point-of-use integration.

- New category of UV Disinfection - Micro UV™

- Advanced flow cell design

- Lightweight/affordable

- Extremely versatile

NSF/ANSI 55-2019

The PearlAqua Micro is Tested and Certified by NSF International against NSF/ANSI 55 for materials and structural integrity requirements.

Micro UV

The PearlAqua Micro debuts the most compact UV system in the world. Highly configurable, this product can be installed directly at the point of use.

Comprehensive Model Line-Up

Models are available for a broad range of flow rates. This allows the user to optimize based on process water conditions.

Flexible Integration

The Micro platform is designed for integration in the tightest places. It allows for the application of UV technology in treatment processes never thought possible.

UV Intensity Monitoring

UV sensor option available to monitor real- time UV intensity within the reactor chamber for mission-critical applications.

Added Flow Switch

The AutoMate utilizes the PearlAqua Micro reactor with added flow sensor features to offer fully automated UV treatment simply with the flow of water.

LEDs do not transfer heat to the water, thus limiting fouling and ensuring a constant UV output regardless of water temperature.

PearlAqua systems are compliant with NSF/ANSI-61 for material safety and NSF/ANSI-372 for lead-free compliance.

The PearlAqua Micro is Tested and Certified by NSF International against NSF/ANSI 55 for materials and structural integrity requirements.

Compliance with Restriction of Hazardous Substances

Worldwide recognition of product meeting all applicable legal provisions.

The PearlAqua Deca™

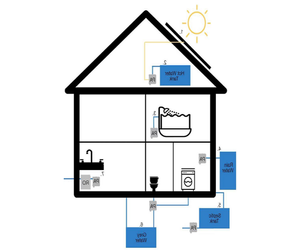

The PearlAqua Deca: is the world`s first UV-C LED Point-of-Entry residential system.

- Advanced UV LED design

- Designed for intermittent flow

- Low cost of ownership

- UV Intensity monitoring standard

PearlAqua Deca: is a UV-C LED water disinfection platform designed for point of use and point of entry applications. This system provides disinfection without the use of harmful chemicals or materials, such as mercury vapor lamps.

First UV LED PoE System

PearlAqua Deca offers the first whole home UV LED disinfection system, offering greater than 99.99% pathogen reduction without the use of harmful materials.

Commercial Application Use

PearlAqua Deca 30C is ideal for point of use applications with higher flow rates such as showers and soda machines, or smaller point of entry applications including RVs, boats, and tiny homes.

Peace of Mind at Home

With UV Intensity monitoring as standard, instant on/off disinfection for intermittent flows, and no hot water shot, the PearlAqua Deca provides advanced UV treatment for the water in your home.

Low Cost of Ownership

Efficient UV LED technology cuts your electric consumption. Designed for intermittent flows, PearlAqua Deca only uses power when water is flowing, drastically reducing the energy needed.

Low Maintenance

The PearlAqua Deca features a 5-year lamp rep I acement i rite rva 1 , reduced mineral fouling, and no handling of fragile lamps or sleeves making it the lowest maintenance option on the market.

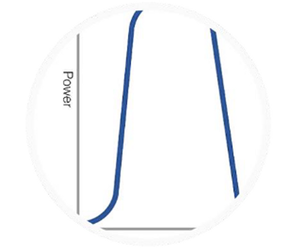

Dynamic Power Control

Beyond instant on/off, features Dynamic Power optimum performance ac saving you money with PearlAqua Deca Control, providing oss all flow rates-lower electric bill.

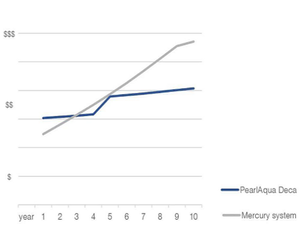

Low Cost of Ownership

The PearlAqua Deca uses less energy and has a longer lamp replacement interval making it a more cost-effective option after 3 years of ownership when compared to a conventional mercury lamp system.

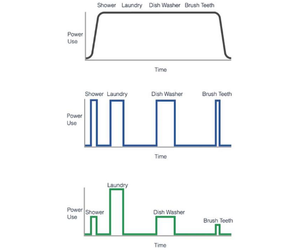

Conventional UV Power Use

Conventional mercury systems are typically left on 24 hours a day 7 days a week due to warm up times and restriction on cycling. This uses unnecessary power if water is not in use, costing money and wasting energy.

Common UV LED Power Use

UV LEDs offer instantaneous on/off capabilities with 100% power within nanoseconds. This however, does not account for the variations in flowrates in whole house systems, so the UV LEDs treat the water at full power 100% of the time.

Dynamic Power Control Only with PearlAqua Deca

Beyond instant on/off capabilities of UV LEDs, PearlAqua Deca features Dynamic Power Control, providing optimum performance across all flow rates– saving you money with a lower electric bill. When low flowrates are detected, the system adapts and lowers the power consumption.

PearlAqua systems are compliant with NSF/ANSI-61 for material safety and NSF/ANSI-372 for lead-free compliance.

The PearlAqua Micro is Tested and Certified by NSF International against NSF/ANSI 55 for materials and structural integrity requirements.

Compliance with Restriction of Hazardous Substances

Worldwide recognition of product meeting all applicable legal provisions.

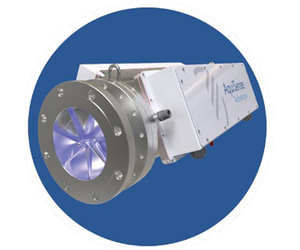

PearlAqua Kilo/Tera

The PearlAqua Kilo/Tera is the world`s largest UV-C LED product platform designed for industrial and municipal water disinfection.

- Maximum Environmental Protection 23

- Replaceable Lamp Module

- Advanced Interface

- Low Cost of Operation

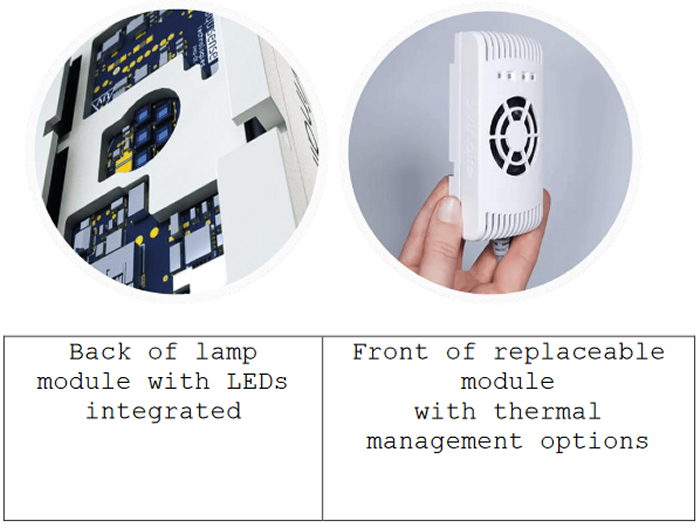

The PearlAqua Kilo & Tera platform is one of the world’s largest UV-C LED products designed for municipal and industrial water disinfection. This flagship system integrates state-of-the-art LEDs into a unique and compact design without the use of chemicals or mercury-based UV lamps.

Maximum Environmental Protection

PearlAqua Kilo/Tera offers the most advanced disinfection without any risk to the environment. Low power requirements and no harmful materials - 24 such as mercury, make the PearlAqua Kilo/Tera the best option.

Replaceable Lamp Module

This advanced module is a replaceable LED lamp that is the heart of the PearlAqua Kilo/Tera. Featuring stable UV-C output power and advanced cooling, the system optimizes consistency and lifetime.

Advanced Interface

The PearlAqua Kilo/Tera offers remote I/O interface for advanced analytic. Real-time UV intensity monitoring provides you with data on your systems` performance

Low Cost of Operation

With instant on/off capabilities, unlimited on/off cycling and low maintenance, the PearlAqua Kilo/Tera provides you with extended treatment without extra cost on parts and maintenance.

PearlAqua systems are compliant with NSF/ANSI-61 for material safety and NSF/ANSI-372 for lead-free compliance.

The PearlAqua Micro is Tested and Certified by NSF International against NSF/ANSI 55 for materials and structural integrity requirements.

Compliance with Restriction of Hazardous Substances.

Worldwide recognition of product meeting all applicable legal provisions.

House Application:

AquiSense can help provide families with the purest water available. The PearlAqua harnesses the power of ultraviolet (UV)

light to destroy pathogens in the most natural way possible, without adding any harmful chemicals. The PearlAqua has been

compactly designed to be a Point-of-Entry (POE) or Point-of-Use (POU) system. Physical filtration of the water is required before UV disinfection so a PearlAqua is a great addition to any existing water treatment system.

The PearlAqua was designed to work with any water treatment system so installation of the unit is easy and retrofitting is simple. Reverse Osmosis (RO) systems remove dissolved inorganic solids from water, but not organic materials or pathogens. This may lead to algae growing in the holding tank, but recirculating the water through a PearlAqua will prevent algae from ever growing.

Traditional UV disinfection systems use a large amount of electricity and heat the water while they disinfect. These systems also use mercury gas-filled lamps to create their UV light. Mercury lamps are very fragile and release mercury into the water stream when they break.

The LEDs inside the PearlAqua last for 10,000 hours. A mercury lamp will have a similar lifespan, but a mercury lamp can only be turned off/on a few times per day. This limitation leads to the lamp remaining on, even when there is no water flow – hence annual replacement. The PearlAqua LED system can be turned on/off an infinite number of times per day, so the unit only runs when water is flowing through it, greatly extending the lamp replacement interval. For example, a PearlAqua unit that is on for 2 hours a day will only need a lamp replacement every 14 years!

With a significantly lower power draw and no annual lamp replacements, the PearlAqua is ideal for any home, boat, camper, or off-the-grid cabin.

PearlAqua Uses in the Home

- DC input power means solar power is possible

- After hot water tank as pathogen barrier

- Point of use legionella control

- Disinfect rain water after storage

- Post septic tank for environmental protection

- Reuse grey water without concern of infection

- RO/filter system final polishing and/or bio-film control

Commercial Application:

UV Disinfection – Effective, Tasteless, Odorless

Traditional UV treatment provides a variety of benefits for commercial applications that require disinfection.

Beyond the safety of your product or process, the quality the consumer expects is just as important. That is why chemical disinfection and other additives can be detrimental. UV disinfection is highly effective at disinfecting pathogens with no residuals found in the end product.

While UV is mostly found in water applications, it can also be used for food, beverages, and white goods. The integration of UV disinfection into a product or process can aid in the resulting quality and safety – thus making your brand more reliable.

Traditional UV disinfection versus UV-C LEDs

While UV disinfection has many benefits, there are some downsides to the most common type of UV disinfection – mercury vapor lamps. Traditional UV disinfection systems can be inefficient in energy use as they are typically left on all the time. These systems also use mercury gas- filled lamps to create their UV light. Mercury lamps are very fragile and release mercury into the water stream when they break.

UV-C LEDs are growing in popularity due to their additive benefits to traditional UV technology. UV-C LEDs provide effective disinfection with a fraction of energy used and require less frequent lamp replacements compared to conventional UV disinfection. This is partly due to the instant on/off capabilities of LEDs, whereas conventional UV typically remains on and degrades over time with frequent on/off cycling.

AquiSense’s PearlAqua product platform use the most advanced UV-C LED disinfection lamps available. The PearlAqua platform is also the most verified and certified product range in the UV-C LED market, making it the perfect choice for integration in a number of commercial applications.

PearlAqua in Commercial Settings

- Water coolers/dispensers

- Ice makers

- Bottled water

- Gray water

- Water tank recirculation

- Food packaging

- Beverages

- “Last mile” water treatment

AquiSense for Healthcare:

UV-C LEDs a new line of defense in medical applications

Hospitals and medical environments must be clean in order for them to operate in any capacity. It is vital that all rooms, equipment, and water that is being used in a medical setting must be sanitized and disinfected. If not, the consequences can be fatal.

UV-C LEDs for water disinfection are changing how hospitals and medical practitioners operate, providing guaranteed water disinfection in a fast and ultra-safe way.

How UV-C LEDs are fast becoming the new line of defense for medical applications

When we looked at the medical applications for our range of UV-C LED devices we saw a need to make life easier and safer for the doctors, nurses, and patients who come into contact with water.

Hospitals while cleaned to the highest standards, is a place where there is a constant influx of sick people who are entering and leaving. It is therefore almost impossible to ensure that no airborne pathogens or harmful bacteria find their way into water systems within the hospitals.

If a central water source within a hospital becomes contaminated it can have immeasurable consequences for patients in that hospital’s care. However, UV-C LEDs are providing a solution to this challenge, able to disinfect water from the point of dispense to water being recirculated in a system. UV LED solutions for water disinfection is quicker than other conventional methods of disinfection, safer for everyone involved in the disinfection process, and easier for doctors and nurses that need clean water at the twist of a tap.

Our PearlAqua range was designed to make life easier and safe for the medical sector, designing our system so that they can be easily fitted and maintained to water systems within a hospital and provide instant disinfection.

How UV-C LEDs can be used in the medical sector

The PearlAqua harnesses the power of UV-C LED light to deliver clean, safe water to those who need it most. The system acts as a final barrier between the human body and the pathogens that attack it; assuring hospitals, nursing homes, and dental offices have the purest water possible.

The PearlAqua can kill pathogens ranging from MRSA (methicillin-resistant Staphylococcus aureus) to Legionella; giving it the potential to prevent 1000s of painful, deadly hospital-acquired infections (HAI). UV-C LED disinfection is

also smaller and safer than traditional UV systems so it can be incorporated into a variety of medical equipment – like autoclaves and dialysis machines.

The benefits of using UV-C LED`s in the medical sector

Healthcare providers who invest in their water invest in their patients’ care.

When doctors and nurses are able to wash their hands in legionella-free sinks, they protect their patients as well as themselves. They can cover their facility with confidence knowing they will not be the reason a child or grandmother contracts an HAI. Healthy healing starts with clean hands and clean hands start with disinfected water.

Take a look at the benefits of using UV-C LEDs:

- UV-C LEDs do not use chemicals or mercury to disinfect

- It’s compact, up to 3 times smaller than traditional UV devices

- Simple, ready-to-use design is easy to install

- Deep UV LEDs reach full intensity in under 10 nanoseconds – Instantaneous On/Off

- No tank required for clean water storage

Applications for UV-C LEDs in the medical sector

There are many applications for UV-C LEDs in the medical sector, from ensuring disinfected water that can be used during operations, to providing ultra- pure water for clinical research.

Other applications for UV-C LEDs include disinfection and integration into medical devices and providing personalized disinfection for staff and patient care.

Our range of PearlAqua UV-C disinfection devices can be applied in a number of ways to the medical sector, get in touch to see how we can help you.

Discover our range of UV-C LED devices

The PearlAqua UV-C LED range pushes the barrier for conventional UV treatment. PearlAqua is not simply a substitute for conventional UV systems rather a game-changer for the medical sector.

As the world’s first UV-C LED product designed for water disinfection. This flagship system integrates state-of-the-art LEDs into a unique and compact design without the use of chemicals or mercury-based UV lamps.

A self-contained, plug and play disinfection system with the most robust construction system, it features:

- Easy installation

- A robust construction

- Small footprint

- Self-Contained system

- Customizable to your needs

- And operates with low power consumption.

Why you should use AquiSense Technologies

At AquiSense Technologies we love a challenge and are dedicated to working on your problem to ensure an innovative solution. As the global leader in UV-C LEDs disinfection modules for homes, industrial and laboratory use, we have

built a reputation as the go-to UV-C LED specialists. Think we can help solve your problem?

AquiSense for Transportation:

UV LED Disinfection – Robust, Lightweight, Flexible Design

Water disinfection for transportation applications comes with a variety of challenges – durability, weight, and power consumption are just a few examples.

Water disinfection challenges for transportation

Whether water disinfection is needed for a fleet of planes, a new line of trains, or even private RVs or boats, clean water is vital for the health of each passenger aboard.

When a sink is found of these vehicles, it is common to find a water storage system with a tank. When reviewing water quality for commercial airlines, the USEPA found a consistent issue with pathogen growths in the water systems on board.

Current disinfection methods

Carbon or ceramic filters could be used to remove the sediment; however, these filters cannot remove micro-organic material allowing bacteria to remain in the system. Bacteria is commonly treated with chemicals, such as chlorine, that

leave by-products in the water to be consumed by unsuspecting customers. Chlorine levels can be difficult to maintain and this is especially true for mobile systems with limited power, space, and personnel. Chlorine treatment also requires periodic testing of the water to ensure the proper level of chlorine is maintained in the water. Further problems exist with the formation of disinfection by-products from chemical treatment and some chlorine resistant pathogens (e.g., cryptosporidium).

Ultraviolet (UV) systems paired with filters are common alternatives when chemicals are no longer an option. When combined, the filter removes sediment and while the UV light irradiates the bacteria’s DNA making the bacteria incapable of

reproducing. However, conventional UV systems utilize fragile, mercury-vapor lamps which are particularly susceptible to breaking in mobile applications. If a lamp was to break during flight, mercury could be absorbed into the water supply. Mercury UV lamps also run on higher voltages and have limited on-off cycles, meaning operational constraints.

Recently developed LEDs that produce deep ultraviolet light, affect bacteria in the same manner as conventional UV lamps, but offer all the typical benefits of semiconductor technology. UV-C LEDs provide the option for a versatile reactor design that caters to space and weight constraints of airlines. Additionally, LEDs are mercury-free and rugged enough to survive the shock specifications, without any risk of mercury contamination. The small size and instant on/off capabilities mean this technology can be placed near the water dispensing point, such as a sink or galley faucet, and switched on only when water is flowing. Disinfecting the water right before it reaches a user, blocks contamination coming from the piping and diminishes the need for residual disinfection chemicals. This new UV-C LED technology gives a new alternative to an on-going water problem the airline industry has been dealing with for decades.

Test applications

A UV-C LED system is being developed under multiple space programs, including two for the International Space Station. The current ISS’s water system is only 88% efficient and uses filtration and chemical technologies. A 2010 study completed by NASA shows bacteria can still grow inside the current water treatment system and recommended an alternative be developed.

The Bio-contamination Integrated Control of Wet Systems for Space Exploration (BIOWYSE) Project was commissioned by the Horizon 2020 program to address the efficiency and disinfection issues within the ISS water treatment system.

BIOWYSE Project is employing UV-C LED technology for water disinfection. This work is showing that UV-C LED systems can be implemented into aerospace applications.

PearlAqua in Transportation Settings

- Aerospace

- Commercial airlines

- Boats/Yachts

- RVs/Camper vans

- Trains/public transportation

AquiSense for Life Sciences:

UV LED research tools – Advancing how we study our world UV light is a key study tool for life sciences as UV light inactivates microorganisms.

UV Research for Life Sciences

UV photons penetrate cells and damage the nucleic acid, rendering them incapable of reproduction, or microbiologically inactive. This process occurs in nature; the sun emits UV rays that perform this way.

UV LEDs in Life Sciences Research

UV represents wavelengths that fall between visible light and x-ray on the electromagnetic spectrum. The UV range can be further divided into UV-A, UV-B, UV-C, and Vacuum-UV. The UV-C portion represents wavelengths from 200 nm – 280 nm, the wavelength used in our LED disinfection products.

Each bacterium, virus or, spore has a unique sensitivity to ultraviolet light. Accurate determination of exposure times and wavelengths is a key step in characterizing cell behavior for any researcher or system designer. Collimating Beam Devices are a critical tool in providing a standardized unit of measurement for UV exposure.

PearlLab in Life Sciences Research

- University Labs

- Government Research

- Regulatory Bodies

- Private Labs

- OEMs investigating UV

AquiSense for Municipalities:

UV LEDs for Municipal Drinking Water

Municipal drinking water applications cover a large variety of systems, from small city treatment plants to large municipalities.

UV-C for Treating Drinking Water

Each facility has unique challenges they face for their disinfection needs. While most use chlorine for drinking water treatment, some find the added benefits of UV disinfection necessary to cover a wider variety of pathogen.

UV is typically used as a last step for the treatment process as it requires relatively high Ultraviolet transmittance (UVT) and can treat pathogens beyond typical chlorine treatment, such as Cryptosporidium and Giardia.

UV LEDs in Municipal Water Treatment

While conventional UV systems have been to leader in municipal systems, UV-C LEDs have been gaining headway in their capabilities, including the flowrates they can treat. Several UV LED manufacturers have designed systems using UV LEDs which promote UV disinfection without the use of mercury.

AquiSense Technologies designed and manufactured the PearlAqua Tera, the first municipal UV LED system in North America. The PearlAqua Tera is being installed in the Las Vegas Valley Water District in Q1 of 2022.