Jiangsu Aceextech Machinery Co., Ltd

- Home

- Companies

- Jiangsu Aceextech Machinery Co., Ltd

- Products

- Aceextech - Model ACE Series - PVC Pipe ...

Most popular related searches

PVC pipe

conical twin screw extruder

automatic belling machine

twin screw extruder

pressure pipe

screw extruder

chain conveyor

pipe system

water pump

machine safety

Conical twin screw extruder

- High specific output for gentle plastification of PVC material

- High melt homogenity even with highfilled material formulations

- Optimized material feeding system for stable production of PVCU powder

- Bimetallic material screw and barrel ensuring long time working without trouble

- Suitable for PVCU highfilled pipe production

- Output range from 150kg/h900kg/h

- Touch screen control panel

- User friendly software developed by Aceextech

- AC motor drive by inverter

- Vertical integrated structured gear box

- Equipped with degassing zone

PVC pipe die head

- Suitable for PVCU and CPVC pipe production

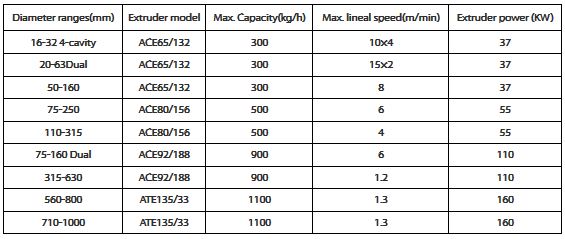

- Diameter range from Ø16 to Ø1000 mm

- High melt homogenity

- Low pressure built up even with high outputs

- Melt channel distribution system

- Equipped with seramic heaters

- Pipe head carriage for easy movement

- Pipe heads are designed according to application requirements.

- Easy maintenance thanks to the optimized and proven designed construction.

Vacuum calibration tank:

- Suitable for PVC pipe production

- Diameter range from Ø16 to Ø1000 mm

- Length up to 12000mm

- 304 stainless steel with painted outer surface

- Special water sprays are located on the best position for cooling the pipe efficiently

- Special and easy adjusted pipe supports for each pipe diameter

- Installed vacuum and water pumps can work without any maintenance for long times

- Special cooling baths can be designed for specific extrusion production

Haul off:

- Pipe range from Ø16 to Ø100 mm

- High pulling force without lose the shape of the pipes

- Equipped with 2, 3, 4, 6, 8 or 10 caterpillars according to the application

- Motorized positioning of the lower caterpillars

Simple operation

- Completely closed protection for maximum safety

- Chain conveyors with special rubber pads on chains which do no mark on the pipe.

- Synchronization with the extruder screw speed allows stable production during changing the production speed.

Planetary cutter:

- Automatic synchronisation with extrusion speed

- Planetary equipped with disk and milling cutter for cut and chamfering

- Touch screen control panel

- User friendly software developed by Aceextech

- All movements are motorised and controlled by control panel

- Pipe blocking vices device

- Type of the cutting unit is chose depend on pipe.

- Less maintenance needs.

- Completely closed and secured machine for maximum safety.

Belling machine:

- Suitable for PVC pipe production

- Universal automatic belling machines for 4 different socketing types

- Diameter range from Ø20 mm to Ø1000 mm

- Socket forming: smooth (solvent cemented)

- Socket forming: shaped for insertion of rubber gasket (blowing system)

- Socket forming: collapsible system

- Socket forming: autoload rubber gasket

- Touch screen control panel

- User friendly software developed

- Automatic synchronisation with extrusion speed

- Pneumatic, hydraulic and motorized movements.

- High quality belling tools.