- Home

- Companies

- Pyreg GmbH

- Products

- Pyreg - Activated Carbon

Pyreg - Activated Carbon

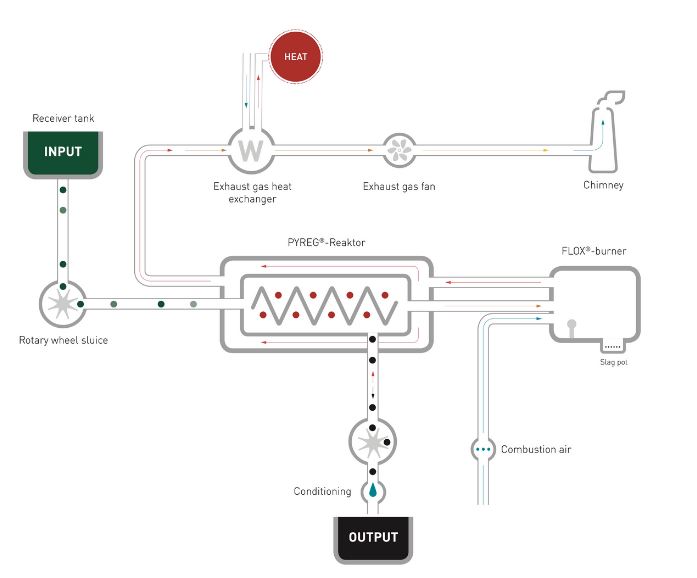

In principle, the carbonisation in the PYREG process is as follows. The dried feed material (at least 65% dry matter content) is fed through the 500-700 °C hot PYREG reactors. There, the material is not burned, but first degassed gently and then carbonised by the addition of specific air. The material is thus completely hygienised.

Since the combustible gases produced in the reactors are completely combusted in a downstream combustion chamber in the FLOX process (flameless oxidation) at around 1,000 °C, the process produces little thermal NOx. This also means that there are no problem substances such as oils or tars, since the carbonisation gas is not cooled but thermally oxidized in the afterburner chamber.

In an optional downstream exhaust gas purification stage, the acidic harmful gases are removed from the exhaust gas in an alkaline flue gas scrubber and volatile sewage sludge components such as mercury are adsorbed onto an activated carbon filter.

A PYREG system is extremely cost-effective and guarantees maximum flexibility. Only a small amount of initial energy is required to operate the compact system. Once the process has started, the PYREG system produces its own operating heat. In addition, further energy contingents are available and can be used for drying or other peripheral uses.