- Home

- Companies

- QED Environmental Systems, Inc

- Products

- QED - Pneumatic Displacement Pump

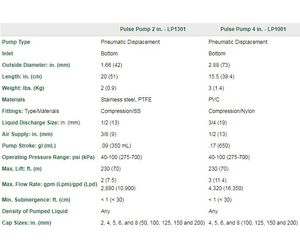

QED - Pneumatic Displacement Pump

Cleanup well conditions can be downright hostile: powerful solvents, gasoline and fuel oil, strong acids, caustic bases, corrosive chlorides. That’s why QED makes the Pulse Pump series (our basic gas displacement pumps) in a variety of proven materials that won’t just survive, but will deliver years of trouble-free performance.

Every Pulse Pump model has only two moving parts downwell: high-clearance, self-cleaning ball check valves. This simplicity keeps them working when high solids, viscosity, or chemical attack cause other pumps to clog or breakdown. An external controller is required to control the alternating pressurization and venting cycles for the pump.

The Pulse Pump design is especially suited for sinking hydrocarbons (DNAPL) recovery, which is often complicated by high viscosity and/or extremely aggressive solvents.

Intrinsically safe Pulse Pump systems are fast and easy to install, with no electrical connections at the wellhead.

Flow optimization is simple too; rugged, dependable pumps and controllers (the solar/AC powered C100M and the all-pneumatic L360) deliver reliable operation without needing frequent attention or repair.

Even in the harshest environments, they just keep working - in the most demanding ground water cleanup, leachate collection, and sinking layer recovery applications.

- Only 2 moving parts downwell for reliable operation even in high solids and the thickest liquids.

- Ultimate resistance to chemical attack. Durable materials and simple, rugged construction.

- Economical, low-maintenance performance in sinking layer recovery and other tough applications.

The Pulse Pump is air-powered and requires an external timer-based controller to control the air cycling OFF and ON to the pump. The external controller provides alternating cycles of venting to allow the pump to fill, and pressurizing to discharge the liquid from the pump. The pump fills through the intake check valve during the refill portion of the cycle, while the pump discharge check valve is sealed. When the external controller applies compressed air to the pump during the discharge cycle, the intake check valve seals and the discharge check valve opens, sending the liquid into the discharge tube to the wellhead. The cycles are then repeated.

The controller options for Pulse Pumps include:- The all-pneumatic L360, with settable refill and discharge times to match site conditions. The L360 cycle controller can be coupled with the L370 level controller to stop pump operation when liquid levels fall below the set point.

- The C100M electronic controller, which can be powered by its built-in solar panel or the included AC adapter. The C100M provides lots of flexibility in cycle times and settable “Off” periods, as well as economical low liquid level shutoff and tank-full float switches. The AC power source is required for continuous pump operation.