- Home

- Companies

- Energy Specialties International (ESI)

- Products

- ESI - Model IGF - Quadair Induced Gas ...

ESI - Model IGF -Quadair Induced Gas Flotation Unit

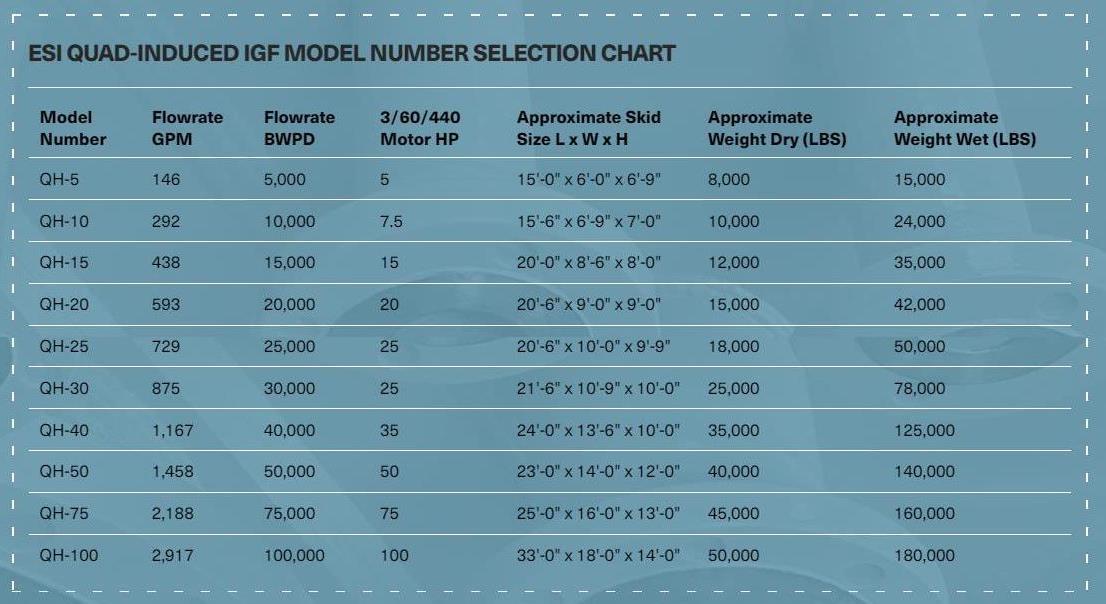

The ESI Quadair Induced Gas Flotation Unit is designed and engineered to remove oil emulsions, suspended solids and organic materials from wastewater. The Quadair requires minimal operating power, uses less floor space and has low installation and maintenance costs. Standard Quadair units are available (see sizing table) & ESI can design special models to meet specific needs. The ESI Quadair Induced Gas Flotation Unit is designed and engineered to remove oil emulsions, suspended solids and organic materials from wastewater.

- Cylindrical Configuration Four Cells

- Over and under Welded Internal Baffles

- Single, Dual or Multiple Eductors per Cell with Needle Valve

- Dual Reject Troughs with Three Skimming Options

- Inlet and Effluent Sample Points

- Internal and External Painting System

- Dual Recirculation Pumps with Associated Valves and Piping

- Controlled and Instrumented per Specifications

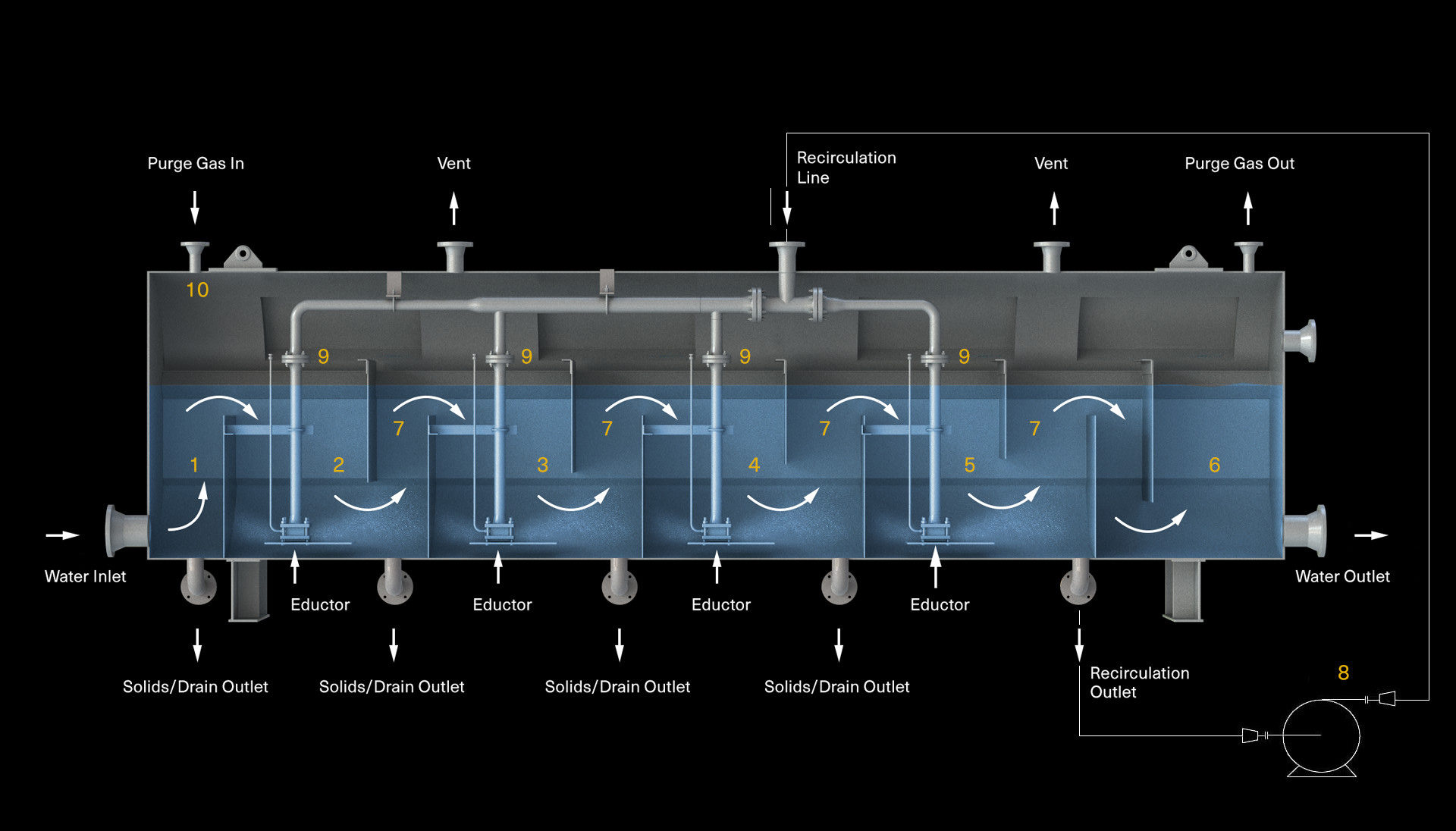

A centrifugal pump (8) recirculates the clean water through a header to an eductor (9) in each flotation cell. Recirculation rate is 50%-125% of the total throughput. The ESI’s Quadair IGF can be equipped with one (1) recirculation pump or with an additional standby pump.

A gas blanket (10) (1-2 oz/sq2) is maintained above the water level to help saturate the liquid. As the recycled water passes through the venturi-type eductor, it creates a slight vacuum pulling gas into the eductor nozzle. Gas flows through a ½” line into a stainless needle valve controlling the amount of gas entering the flotation cell. By controlling the gas induced, the proper bubble size and pattern for efficient lifting of suspended solids and oils is achieved.