- Home

- Companies

- EMI sp. z o.o.

- Products

- QuickMBR - Model QMBR - Packaged MBR ...

QuickMBR - Model QMBR -Packaged MBR treatment plant

Fast and dynamic business environment requires solutions which are quick in deployment, easy to operate and capable of providing reliable performance. EMI QuickMBR was developed to address these needs.

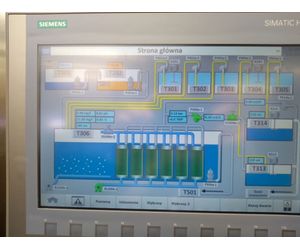

QuickMBR is a packed plant assembled in EMI production facility and shipped to customer with all elements required to treat industrial wastewater. It features mechanical treatment and a membrane biological reactor, together with all auxiliary equipment and controls.

Plant design was optimized for achieving best performance on limited footprint. Our basic unit fits in a standard 40-foot/12meter container and is capable of handling:

Flow of up to 120 m³/d

COD load of up to 5 000 mg/l

QuickMBR has a distinct set of features which make it uniquely easy to install and operate. All of media can be quickly connected on flanges, there is a built-in CIP system with all dosing pumps. Control software and hardware allow remote access.

The container is custom-built to enable year-round operations with heating and ventilation. Inner walls, ceiling and floor are made of stainless steel for life-long durability.

We have also applied strict protocols for health and safety without compromising overall usability.

From all-in-one containers with retention and reaction tanks, screens and MBR modules delivered in a single 40ft container up to more complex setups with underground tanks. QuickMBR was designed as a modular platform for wide range of capacities from 20 to 1000 m³/day

Each QuickMBR uses biological treatment followed by membrane ultrafiltration. Wastewater cycles through anoxic and aerated zones of the reactor to facilitate nitrification and denitrification processes. Activated sludge is kept at high concentration for increased efficiency and separated physically on membranes without the need for controlled sedimentation. Ultrafiltration removes virtually all suspended solids, allowing for obtaining ultimate clarity and high reduction rates for COD and other parameters.

Sea containers are perfect for transport, but we had to re-design their interior. QuickMBR is more of a machine than a building. We have equipped it with stainless steel lining, insulation, hydraulic and electrical installations as well as ventilation and lighting. All cable ducts, pipelines and fittings were carefully selected for tight spaces so that maintenance is not only possible but also convenient.

QuickMBR has a modular design and comes pre-assembled. This does not limit the ability to customize the design and make it fit the purpose. Our customers may choose among many accessories like ladders, hatches, covers, etc. We work with several renowned suppliers of pumps and fittings, so we can match the ones used in the production plant to lower maintenance costs. Optional equipment list includes UV disinfection, LTE connectivity set, custom external painting, and many others.