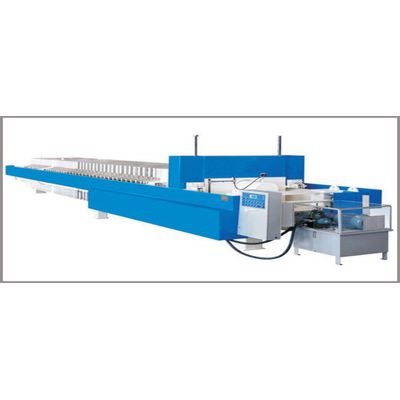

Royal - Recessed Chamber Filter Presses

Chamber Filter Press is the traditional recessed chamber filter press operation employs a steady increase in pressure over time as the cake thickness increases, in order to achieve the optimum combination of chamber filling and cake dryness. At a significantly reduced filtrate rate, the filtration is stopped, the press discharged and a new cycle started. Chamber filter presses are reliable and robust in many different applications. The plate pack consists of uniform chamber plates with a recess of 15 - 50 mm to from the filter cake. A chamber plate is a combination of a filter plate and two half frames in once piece. The standard material for chamber plates is Polypropylene. Possible operating pressures: 7, 15 and to the max of 24 bar (kg/cm2).

- Edible Oil.

- Effluent Treatment plants.

- Chemical plants.

- Ceramic and China Clay filtration.

- Titanium plants..etc..

- Plate size ranging from 470 x 470mm to 1500 x 1500 mm.

- MOC: PP .

- Pressure: up to 16 bar.

- Controls: Fully automatic /Semi Automatic/ Manual.

- Hydraulics: up to 250 Tons.

- Complete automatic cycle option.

- Boom drip tray.