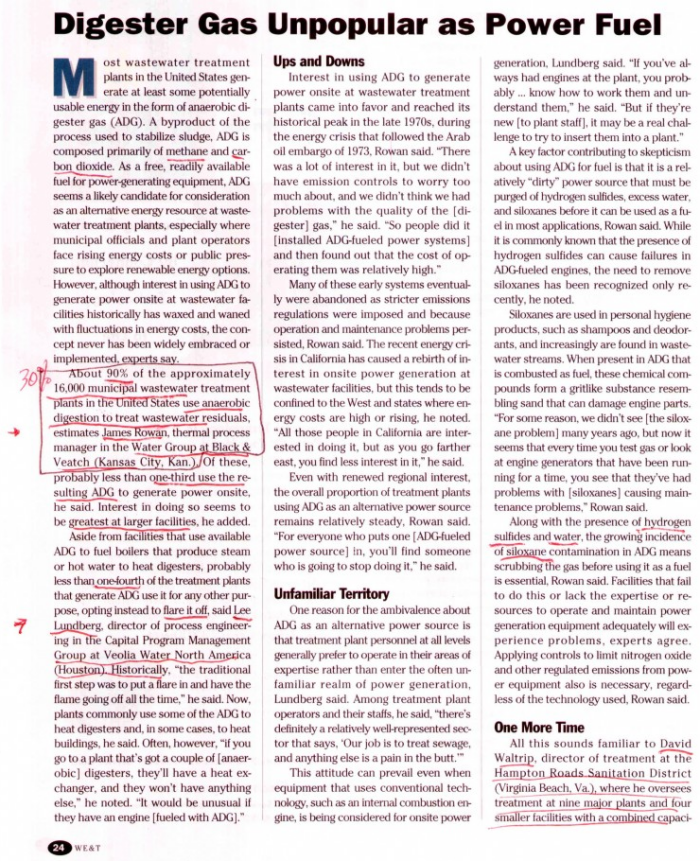

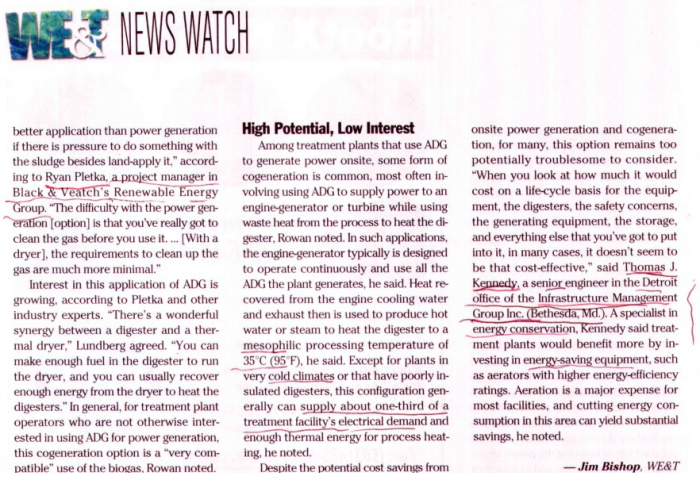

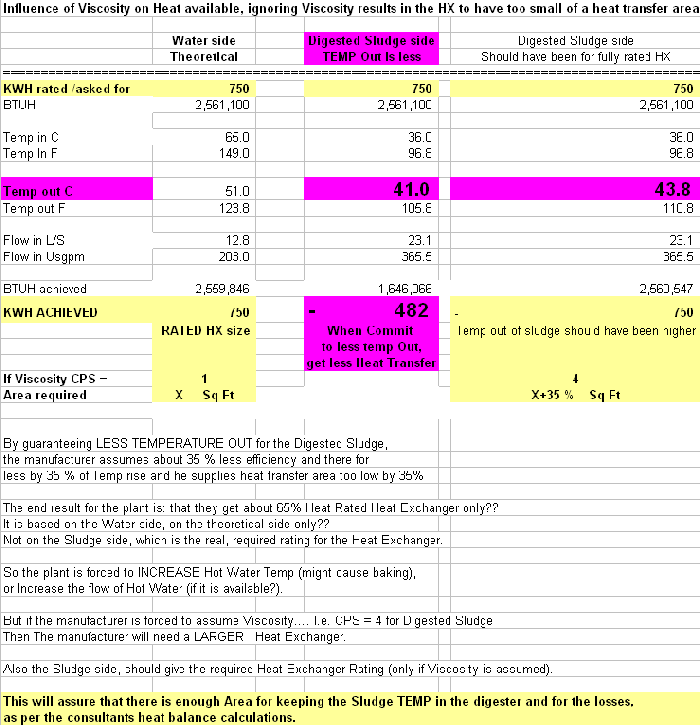

DDI - Rectangular Channeled Heat Exchanger

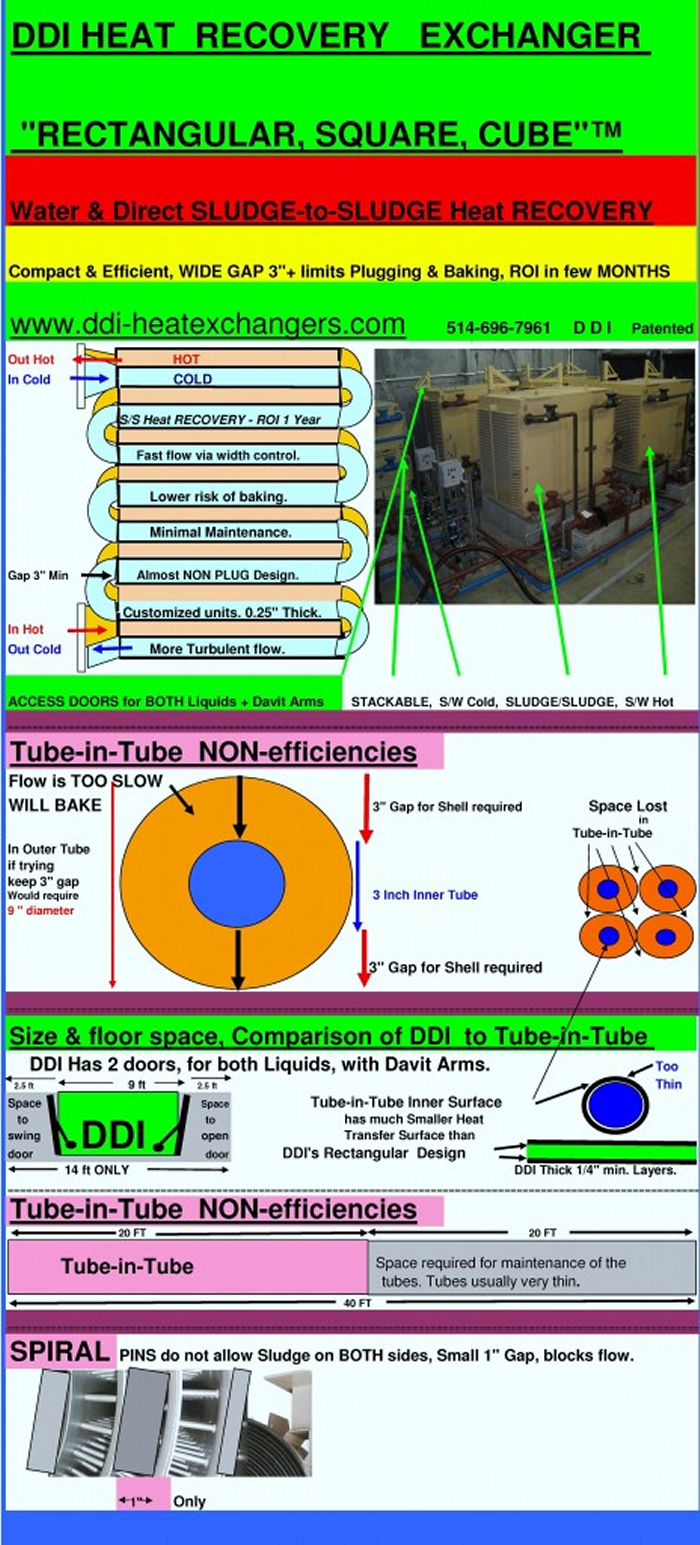

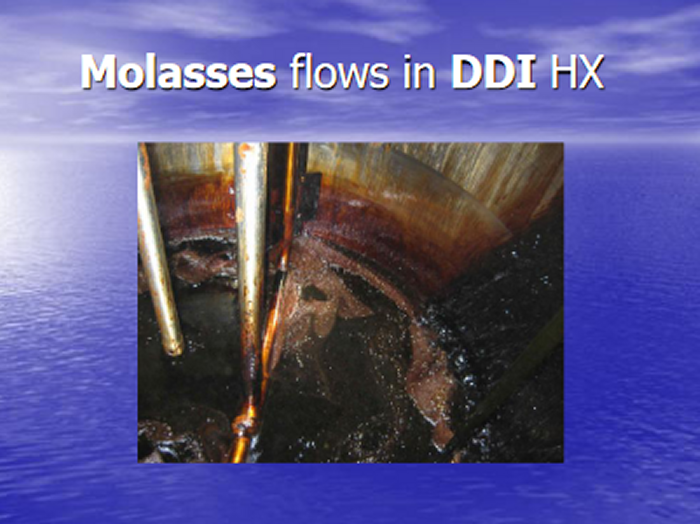

The 3 key advantages of our DDI technology are due to our Patented Technology of Rectangular channeled heat exchangers.It is not the common tube-in-shell technology nor the common Spiral structure of heat exchangers. WE BUY YOUR WASTE. Worlds only direct SLUDGE TO SLUDGE heat recovery.

- We can control the Height or GAP of the rectangular channel.

- So if we make it larger than the opening of the pump which flows the sewage or grey water or waste water or laundry or any other liquid with high % solids, than our heat exchangers will not get plugged.

We demonstrated that with 26% solids liquid flowing in our heat exchangers via a project with reference from HDR Engineering. - Therefor we can also recover the wasted heat or coolant from the city Sewage that flows below the street without plugging. With ROI of 1-2 years.

- Due the Rectangular channel. We can control how wide to make the WIDTH of the channel so as to achieve high flows, so we lower the risk of BAKING to the surface.

- Again with HDR Engineering we had liquid flows at 600 deg f without BAKING to the surface.

We can have both liquids to have very high % of solids. The hot wasted processed sludge can recover its heat to the cold raw sludge entering the waste water treatment plant with a ROI of 5-8 month. - Because of the Rectangular channels we can have double plates in between the 2 liquids. That allows us to comply with the law requiring double wall between the hot wasted dirty grey or black water leaving the high rise hotel or large condo building. And between the clear water on the other side of the heat exchanger which we preheat before it flows to the central boiler.

- Therefore we can recover the wasted grey water in large buildings that other technologies can not do.

- ROI is about 1-2 years, depending on the hotel size.

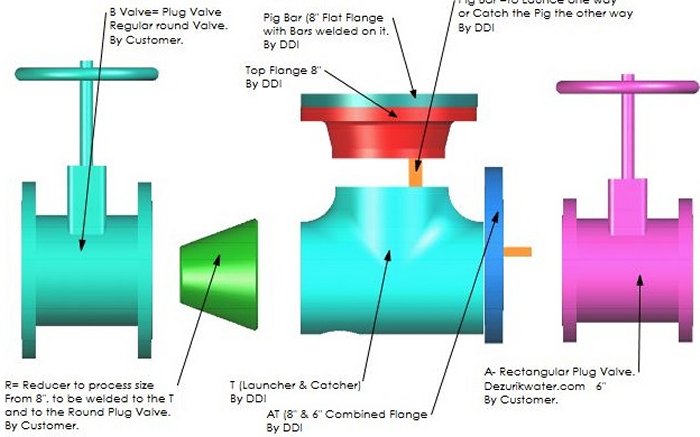

The advantages of using DDI- ECPS- CLEANING PORTS instead of a DOOR and Davit Arm on a Heat Exchanger.

- When and if ever plugging occurs- and after automatic back flash option used or not, the next easiest way to clean inside is mechanically via Cleaning Ports at each Channel. It takes only a few seconds to open a Cover Cap of a Cleaning port, instead of all the bolts that hold the door.

- We are investigating ways to zoom directly on the correct plugged channel, so as to open only that Cleaning port.

- We can use the methodic system of starting with a channel in the middle and then knowing if the plugging is in the top half or the bottom half, and then to open a port in the quarter section etc till we zoom on the correct channel. Even in this way we might turn 10 caps, it is only a question of a few seconds each. Compared to 2-3 hours or so to remove all bolts of a door and then to reinstall the door and change a gasket.

- No risk of leakage in the gasket area.

- The Heat Exchanger is less expensive.

- No need for Davit Arm.

- No need to change Gaskets.

- Less weight.

- Faster delivery time.

Why DDI has no Struvite nor Vivianite problems?

(In French below),

Why DDI heat exchangers did never had any STRIUVITE problems. In 42 Installations. In 18 years.

DDI Rectangular Patented Technology.

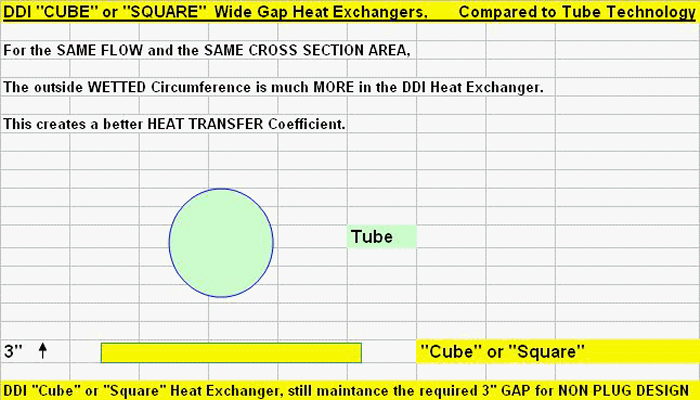

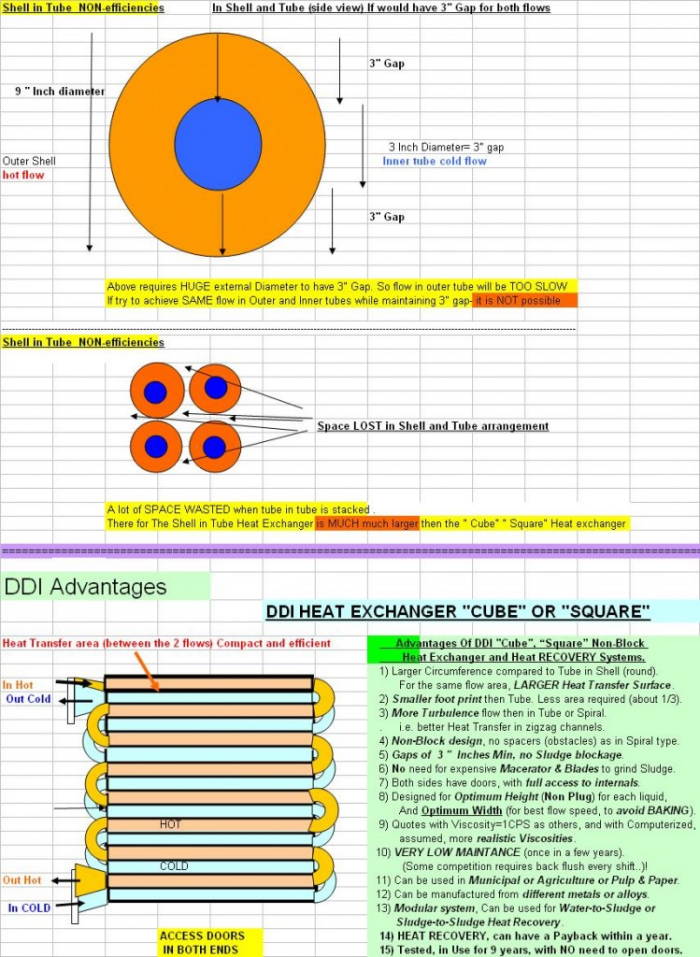

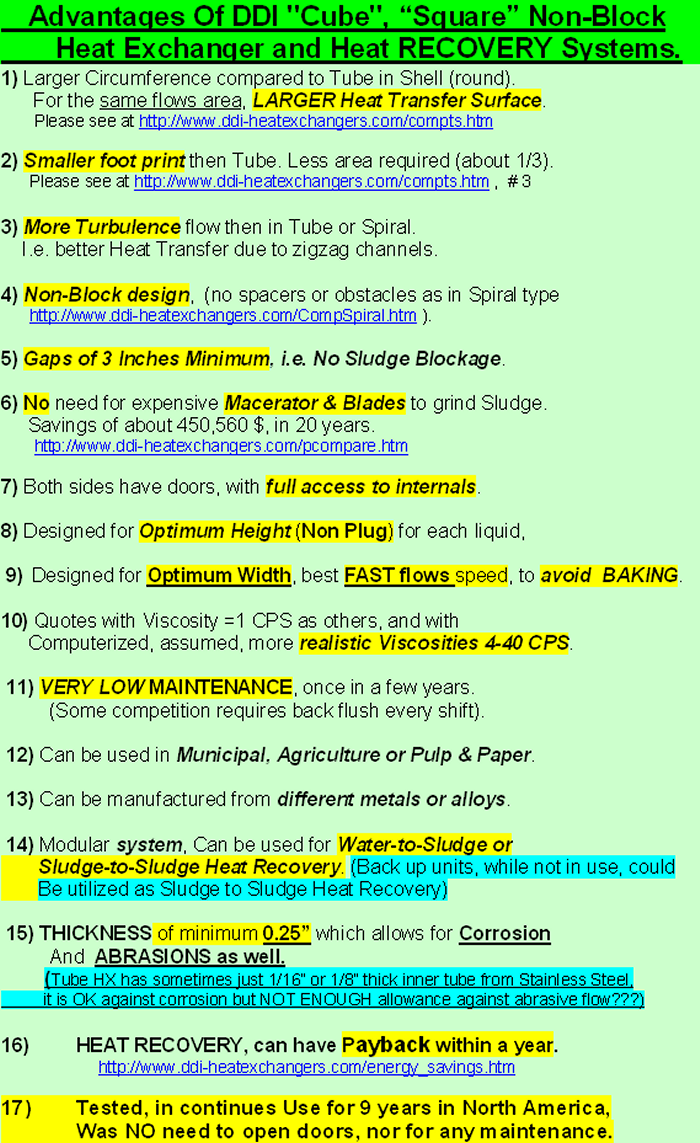

1. Larger Circumference compared to Tube in Shell (round).

For the same flow area, LARGER Heat Transfer Surface.

SO LESS STRUVITE STICKING TO THE LARGER…. SURFACE

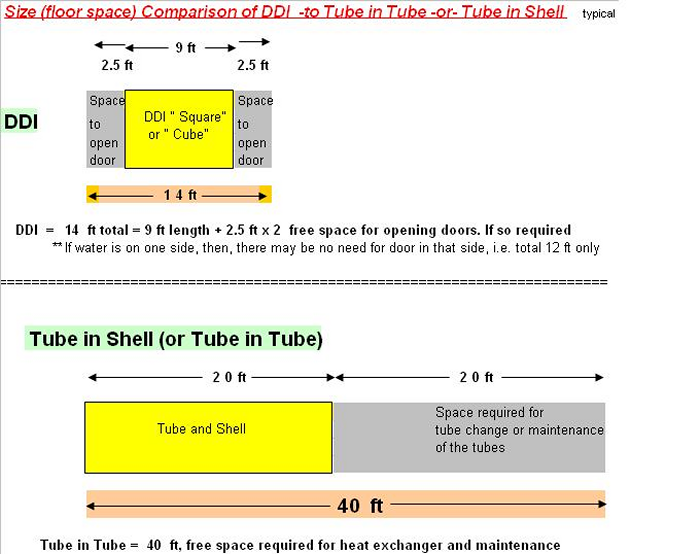

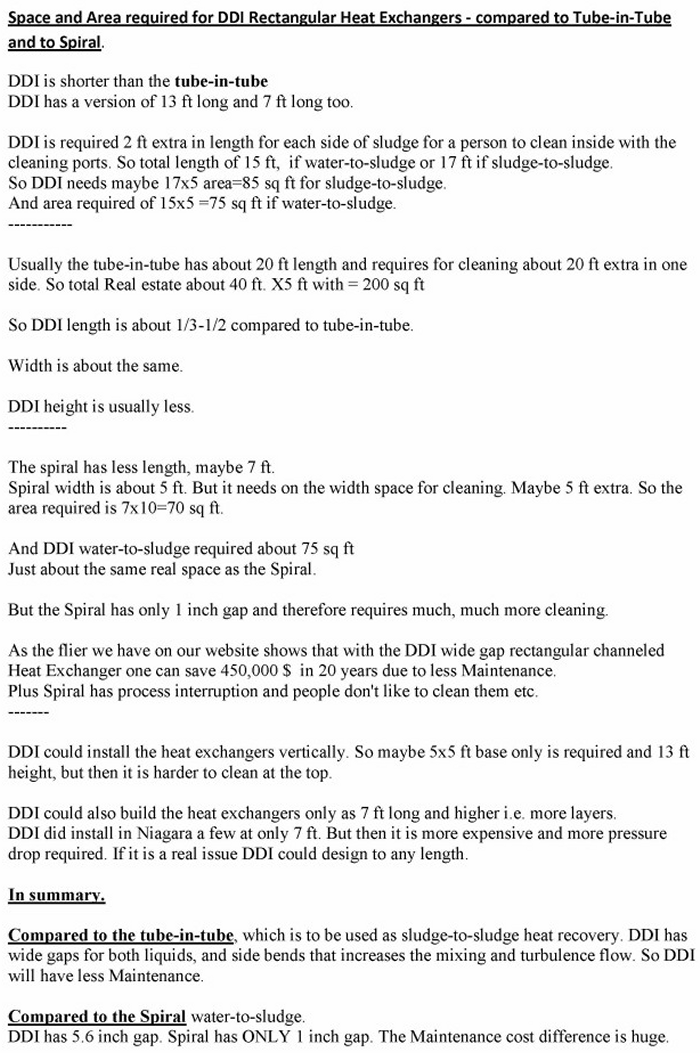

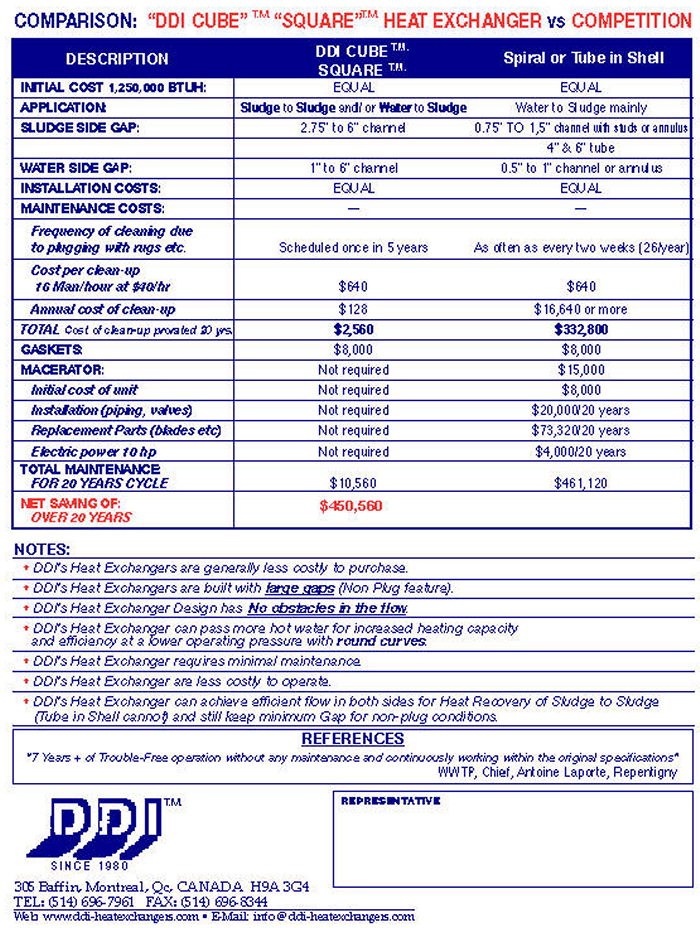

2. Smaller foot print than Tube. Less area required.

3.More Turbulence flow than in Tube-in-Tube or Spiral.

i.e. better Heat Transfer in zigzag channels. Outside bends

SO LESS STRUVITE.

4. Non-Block design, no spacers (obstacles) as in Spiral type.

5. Gaps of 2, 3, 4 Inches Min, no Sludge blockage.

SO LESS STRUVITE.

6. No need for expensive Macerator & Blades to grind Sludge.

7. “ECPS” tm “Easy Cleaning Ports System” to clean inside in minutes.

SO LESS STRUVITE problems if ever will happen. Will take MINUTES only to clean inside.

8. Designed for Optimum Height (Non Plug) for each liquid,

SO LESS STRUVITE.

And Optimum Width (for best flow speed, to avoid BAKING).

SO LESS STRUVITE.

9 VERY LOW MAINTANCE (once in a few years).

(Some competition requires back flush every shift).

10. Can be used in Municipal, Agriculture, Pulp & Paper, Industrial etc.

HUGE DDI EXPERIANCE in WWTP installations.

See references on the web.

11 . Can be manufactured from different metals or alloys.

12. Modular system, can be used for Water-to-Sludge or

Sludge-to-Sludge Heat Recovery.

Stackable to save space and piping and more efficient.

13. HEAT RECOVERY, can have Payback ROI within 1 year.

14. Tested, in Use for 18 years, 42 installation, with NO need clean inside.

To view a heat-transfer efficiency comparison, click here.

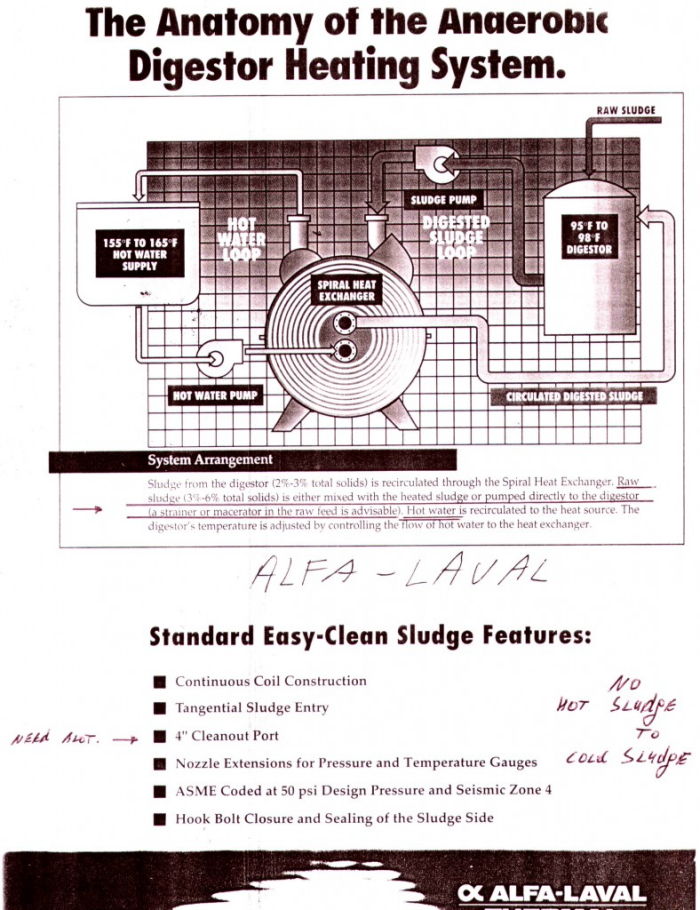

“However, the system is more complex and requires greater operator attention, primarily in the equalization and heat-recovery steps and in ensuring continuous feeding of the raw solids. From the outset, plugging problems have plagued the spiral heat exchangers, …”

“In most early projects, conventional heat exchangers were used with little or no modification. Unless coupled with equipment that screens out debris, this arrangement may require frequent maintenance.”

“… the need for heat recovery, and the increased instrumentation and control required for advanced digestion will increase maintenance requirements for most facilities.”

AN ASSESSMENT OF AGRICULTURE CANADA’S

ANAEROBIC DIGESTION PROGRAM

Research Branch, Agriculture Canada

Engineering and Statistical Research Center

P. Van Die

“Fairly complex digestion system designs were developed. Manure screening is almost essential to prevent plugging and reliable components such as circulation pumps, heat exchangers and temporary biogas storages are essential. Current systems lack reliability and have high maintenance requirement.”

Sludge and Scum Screening At The Annacis Island Wastewater Treatment Plant

Contact: mahl@burnaby.associated-eng.com

“In 1991, the Greater Vancouver Regional district began design of the upgrade of the Annacis Island Wastewater Treatment Plant to secondary treatment. During the design, the District adopted a policy requiring that all biosolids generated from treatment be used beneficially. Removing debris from the biosolids is considered crucial to developing market acceptance of the product. In addition, removing or grinding material larger then 12 mm in the solids stream is required to avoid blocking process equipment. In North America, grinders are most commonly used to macerate sludge and scum. In Europe, screens with an opening size of 10 mm or less have been successfully used for removing debris from solids streams. The advantages of screening over grinding are lower capital cost if a significant number of grinders can be eliminated, a reduction in the quantity of debris entering the maintenance of equipment in the digester area, and less debris in the digested biosolids. Sludge and scum screens began operation in April 1996. This paper discusses the rationale behind the selection of these screening processes, the technology selection and design, and initial operation of the screens.’

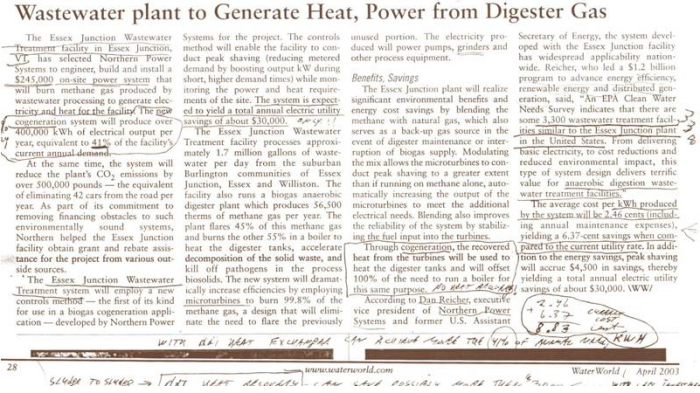

Subject: Cogeneration

An independent article from WaterWorld (April 2003).

A) For Cogeneration – They will spend 245,000 $ to save 30,000 $ per year.

Compared to DDI “Cube” or “ Square” Heat Exchanger that will cost (for example) 97,900$ (with installation) and will save about 366,000 $ PER YEAR as Sludge to Sludge Heat Recovery system.

B) DDI Heat Exchanger will probably have less maintenance cost then the Micro-Turbines in the Cogeneration solution.

C) Market has over 3,300 Anaerobic Digestion Waste Water Treatment Facilities, (Maybe x 3 Heat Exchangers). So many, many WWTF can use Heat Recovery.

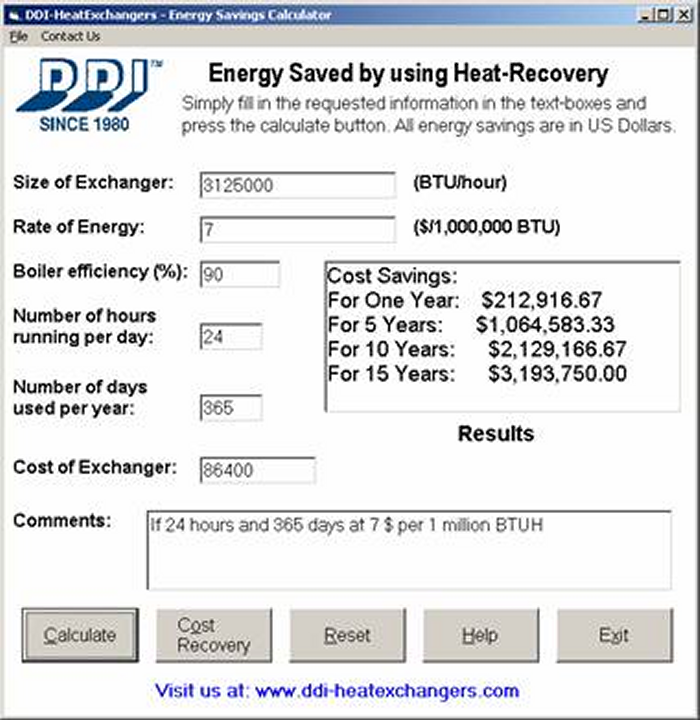

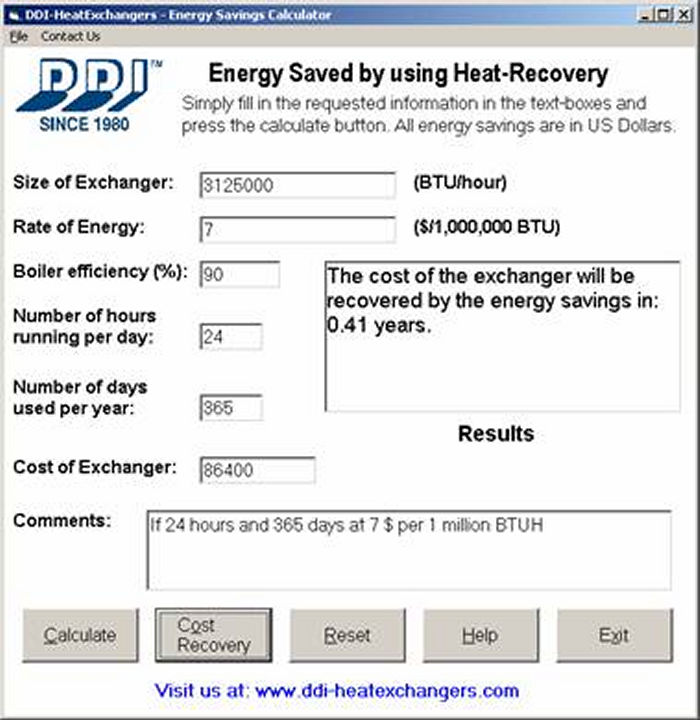

D) DDI estimated cost per 1 million BTUH at Minimum 7 $ only. (Now it is much higher). See “Energy Saved by using Heat-Recovery” program on the web

This study claims cost at 24.3 $ per 1 million BTUH

(1 KWH = 3415 BTUH

292.8 KWH = 1 million BTUH

Cost per KWH 2.46 +6.37 = 8.83 cents

292.8 x 0.083 $ / KWH = cost per 1 million BTUH = 24.3 $ = cost for 1,000,000 BTUH

E) Cogeneration will generate ONLY 41 % of Annual Energy demand in the plant.

But with DDI Heat Recovery System installed they can achieve much more.