TECAM

Tecam Group - Model RCO -Regenerative Catalytic Oxidizers

FromTECAM

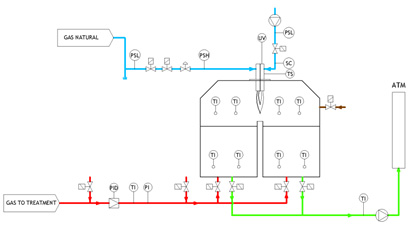

Regenerative Catalytic Oxidizers RCO have lower operating costs for VOC emissions treatment than any other exhaust air emission control solutions, and it is more compact, thus reducing the space needed for the equipment. The oxidation reaction is performed on a high performance catalysing bed. Tecam Group designs, manufactures and installs equipment for Volatile Organic Compound VOC emissions treatment through Regenerative Catalytic Oxidizer technology (RCO).

Most popular related searches

regenerative catalytic oxidizer

catalytic oxidizer

catalytic oxidation

VOC emissions treatment

air emissions control system

volatile organic compounds

VOC emissions

exhaust air treatment

air emissions control

emissions control system

- Air Volumes from 1,000 to 30,000 m3/h

- Low to Medium Solvent Concentrations

- Compact Solution – Does Not Require Much Space

- Lower Operating Cost than other Solutions for VOC emission treatment

- Combustion Gas Treatment

- Does not Generate any Waste

Regenerative Catalytic Oxidizers work in a similar way as other VOC emissions treatment thermal system, with the main difference that gas, after going through the flame area, goes directly to the ceramic bed to generate heat, to be taken advantage of for oxidation.

- Auto thermal point 0.6-0.8g/Nm3

- High efficiency of the heat exchanger 98 %

- No gas consumption at auto thermal point

- Long life catalytic material

- Full automatic operation

- Low operation cost

- Easy Installation

- Installed inside a 20- or 40-feet container

- Electrical Cabinet

- Filter

- Catalytic Beds

- Valves

- Fan

- Container