Tecnidro - Model Hydronet -Remote Reading and Control Radio System for Water Distribuon Networks

Saving water resources is nowa priority objective in the management of distribution networks, but remains difficult to achieve without the support of specific and reliable automation technologies. With over 30 years of experience in the production of hydraulic equipment, TECNIDRO introduces to the market an innovative solution proposing HYDRONET system, based on the latest LPWAN radio transmission technologies. HYDRONET has been specifically designed for public water management networks on geographical areas as well as for plants with a more limited extension belonging to farm and private companies.

The system operates on a near real-time basis allowing the remote acquisition of water flows and volumes, the opening / closing of valves at the network distribution nodes, the monitoring of the operating parameters (pressure, temperature, humidity, etc.), the notification of alarms and the processing of the data collected for the subsequent historical analysis and the possible invoicing of the fees.

The HYDRONET radio system guarantees a reliable, safe and protected from fraud and vandalism, taking into account the peculiar characteristics of agricultural irrigation networks, usually characterized by a high number of water delivery points, grouped or installed individually in large perimeters, subject to critical environmental conditions and typically without any electricity sources.

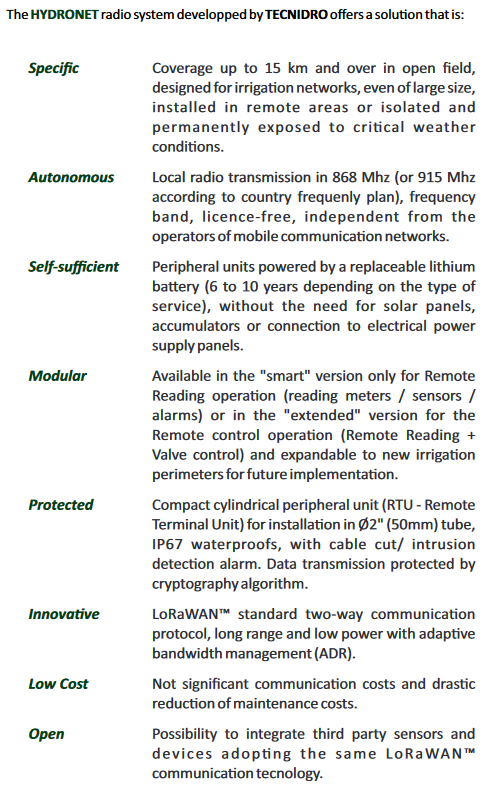

loT - Internet of Things

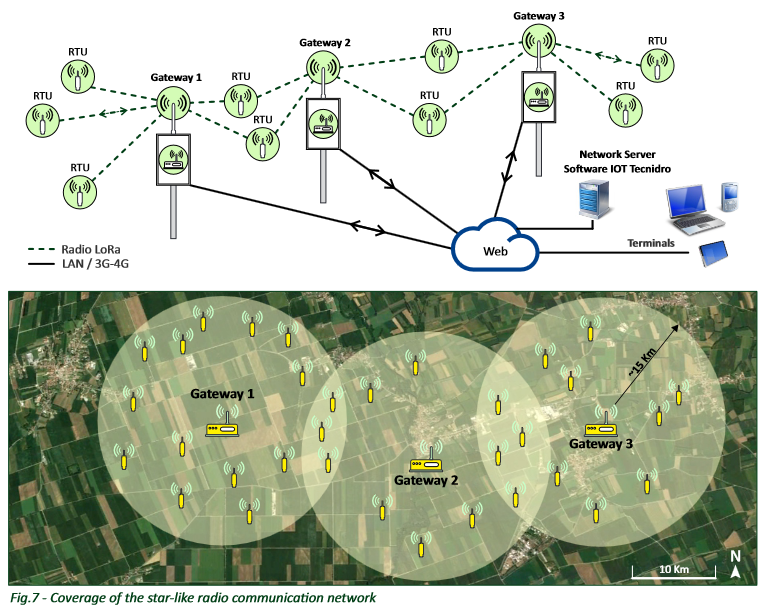

The HYDRONET radio system has been designed by TECNIDRO by adopting the innovative LoRa® (Long Range) point-to-point wireless communication technology, developed to create networks with low-power and wide-range devices (LPWAN - Low Power Wide Area Network), key-issue forthe application of the Internet of Things (loT).

The open communication protocol LoRaWAN™, developed by LoRa Alliance ™ and based on LoRa® technology, ensures that all devices (End Nodes), servers and software components of the system are interoperable with each other, ensuring a high standard of security for the loT communications. The HYDRONET solution can integrate a variety of other third party devices provided with the same LoRaWAN™ technology, such as meteorological station, field sensors/transducers etc.

The management of an irrigaon network may involve different needs:

- limited only to the periodic reading of the volumes of water supplied in different nodes of the plant and to the monitoring of the network operang parameters (for example the pressure in the pipeline or the level of a reservoir);

- extended to the scheduling of irrigaon shis with the acvaon of valves in the field or to the occasional/seasonal interrupon of irrigaon at different network levels (sector or an enre perimeter).

In some cases, irrigaon networks may have mixed needs, requiring the control and monitoring of the main distribuon network and the acquision of secondary network volumes/parameters. The system sasfies all the possible needs being able to manage different configuraons (Fig.1):HYDRONET

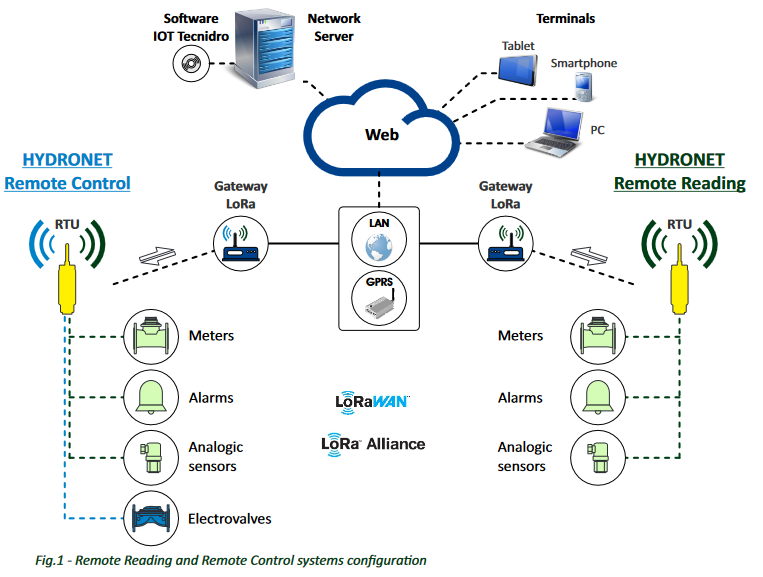

Remote reading: the system allows the remote reading of the flow rates and volumes measured by the water meters, the detecon and management of the alarms (cable cut and/or intrusion) and the acquision of an analogue signal acquired at the managed point, (pressure, temperature, level, etc.). This configuraon is typical in public distribuon networks (Fig.2), where the Water Administrator operates just to collect informaon (water flow/volumes) to properly invoice the consumpons of the users and/or to keep under control the main nodes of the water network.

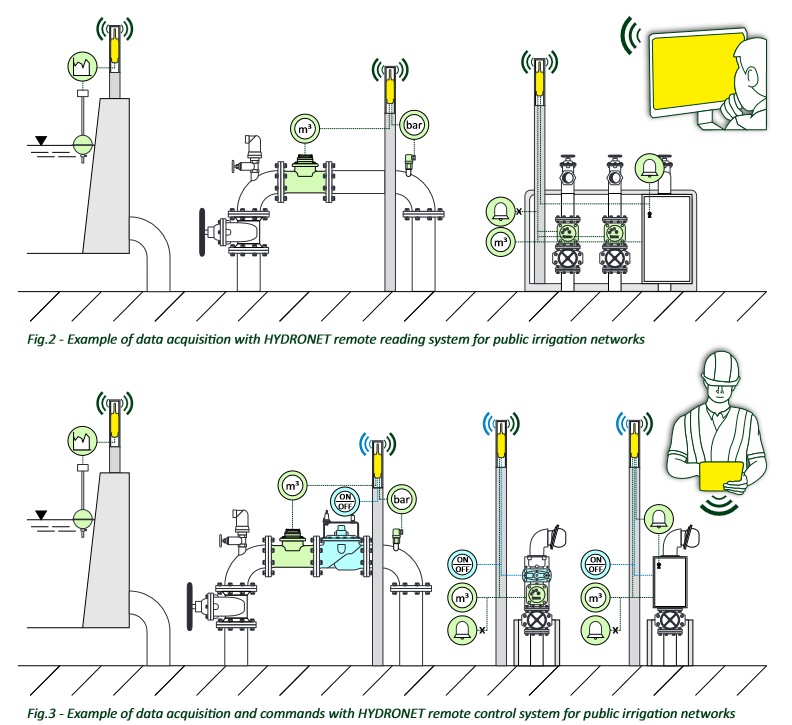

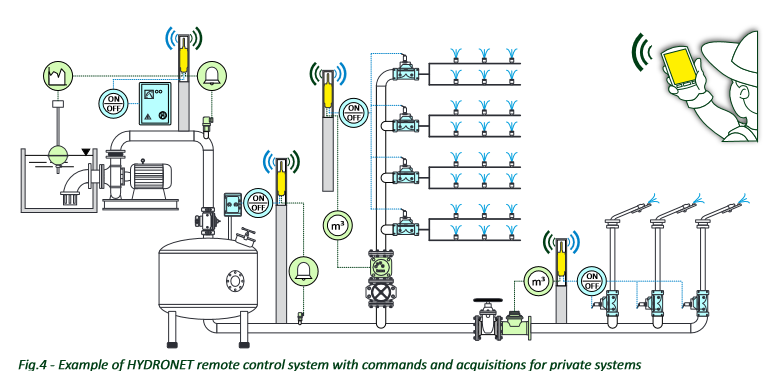

Remote control: the system maintains all the funcons of acquision of the remote reading and integrates those with the remote control of hydraulic valves (through solenoid valve), also allowing to program their cyclic opening / closing or to execute immediate commands. This configuraon is suitable for both the public service (Fig.3), which needs to manage the users shiing and the scheduled maintenance intervenons, and for the automaon of private systems (Fig.4), where capability to program the openings/closures at sector level and the control of the main network are key points for the management

In addition to the large radio coverage capability, the HYDRONET system offers further advantages, easily managing in almost real time (Near Real Time) a very large number of remote devices.

Communication between the RTUs and the Gateway is completed in a very short time (up to 2 minutes for 1,000 managed points) and the transmission interval can be programmed at the most suitable value for the system, preserving the battery life.

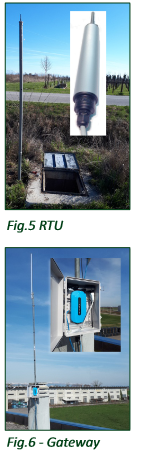

Each Gateway is designed to manage up to a maximum recommended of 256 uniquely coded RTU units, thus concentrating the communication of a network composed of over 1,000 devices including meters, valves, sensors and more.

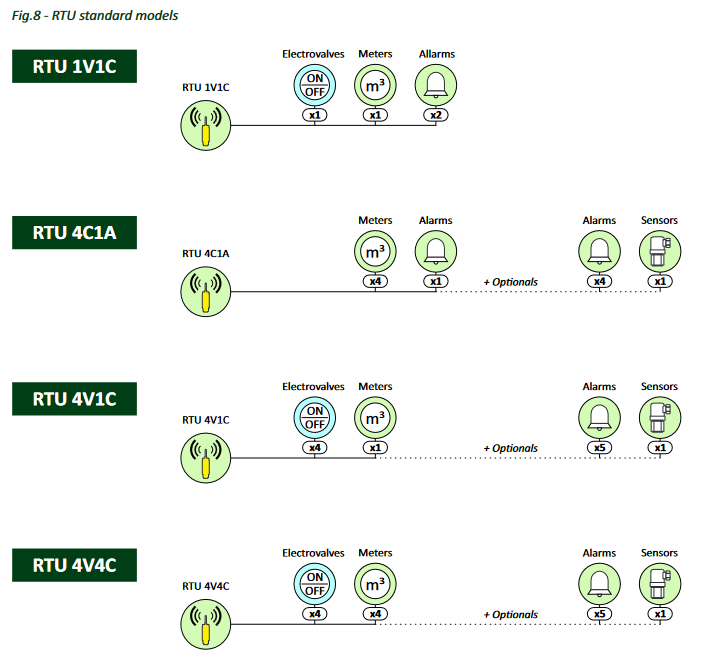

The total number of field devices that can be connected to the peripherals depends on the number of outputs and inputs used by the RTUs, which are available in different standard models (Fig.8) to adapt to the specific needs of each type of system. The electronics of the RTU is designed to manage up to:

- n. 4 digital outputs for solenoid valve control

- n. 4 impulsive inputs for water meter reading

- n. 5 digital status / alarm inputs (valve status, cable cut, intrusion, etc.)

- n. 1 analogue input for sensor acquision (pressure, level, temperature, etc.)

The availability of electronic inputs and outputs can be fully exploited in relaon to the type of RTU adopted (R-Tube or R-Box

version)