- Home

- Companies

- Graham Engineering Company, LLC

- Products

- Revolution MVP - Rotary Wheel Blow ...

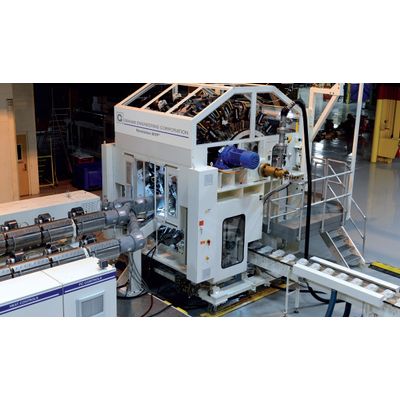

Revolution MVP - Rotary Wheel Blow Molder

The precision and output of a Graham Wheel with the flexibility of a shuttle. Our innovative modular clamp design combined with the new variable pitch feature forms the basis for the Revolution MVP. Combined with our “Quick Change” mold system, this revolutionary new design offers the precision and output you expect of a Graham Wheel, along with the flexibility of a shuttle.

- Able to produce bottles up to 16” (41cm) tall

- Capable of varying bottle height up to 28% within a configuration

- Quick-Change™ molds ~5 minutes per station

- Capable of up to 8 RPM & 11,520 BPH (single parison) — 46,080 BPH (dual parison, neck-to-neck)

Modular Clamp Station

Unprecedented Flexibility for Product Changes

A key Graham Engineering innovation at the heart of the Revolution MVP is the Modular Clamp Station. Each clamp station is independent of the others, and all forces are self-contained within the clamp. Water manifolds through the platens and the individual clamps are removable for offline maintenance to reduce downtime. This modularity enables the number of clamp stations to vary from 12 to 24 based on your needs. That also allows variations in configuration based on application and bottle height.

Variable Pitch

Easy, Fast, Reliable

The variable pitch innovation creates a multiplier effect enabling 100 possible positions, with each clamp station adjustable in 1 inch increments, from 39 inches to 47 inches. This not only enables a range of bottle sizes up to 16” in height to be run on a single platform, but also provides flash optimization at each bottle height, particularly important for multilayer applications. Once again, we engineer with your time in mind, it takes about 5 minutes per clamp station to vary the pitch in a simple process. Simply loosen bolts on each side of the clamp, adjust the radius inward or outward, and then reset the pin and retighten the bolts.

- Intuitive navigation

- Integrated screen map & help pages

- 2 Keystrokes maximum to any screen

- Closed-loop extruder control

- Operator-adjusted speeds & set value change recording

- Alarm history reports and password security control

- Integrated trending package

- Remote support and trouble-shooting

- Integrated recipe manager

- Detailed machine manual accessible via HMI