- Home

- Companies

- RGF Environmental Group, Inc.

- Products

- RGF - Model TO - Thermo-Oxidizer Dry ...

RGF - Model TO -Thermo-Oxidizer Dry Chamber Flash Evaporation System

The RGF Thermo Oxidizers are a unique method of liquid destruction. Through Flash Evaporation the liquid waste is atomized and sprayed under pressure into a dry ceramic refractory lined chamber. At 1250°F all VOC’s and organics are oxidized, and dissolved and suspended solids are oxidized to ash. Solid contaminants are reduced to a powdered inorganic ash for easy removal. The unit eliminates the typical evaporator problems of corrosion, foaming, residual slurry, V.O.C. emissions, and difficult to clean evaporator chambers. By utilizing an optional waste oil burner, the system can eliminate both waste oil and wastewater.

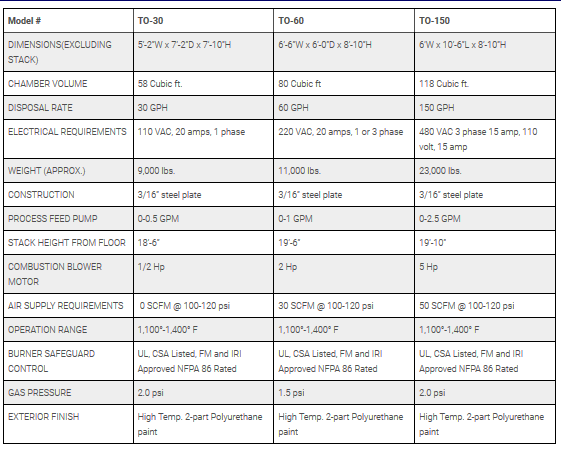

The RGF Thermo-Oxidizer evaporates water from 30 to 150 gallons per hour and is controlled by a combination PLC and UL approved microprocessor based Flame Safeguard Controller. Visual confirmation of the Thermo-Oxidizer status is provided by LCD displays, indicator lights, and digital temperature displays. The stainless steel burner nozzle provides the energy necessary for the waste water evaporation. A pump pressurizes the waste water for injection into the air atomization nozzles. The waste water stream is thereby atomized directly into the combustion chamber where it is completely evaporated, leaving only a dry ash to dispose of.

- RGF is the recognized leader with thousands of systems installed worldwide since 1985.

- Multiple safety system controls.

- Handles a wide range of waste.

- Pre-wired, fully automatic, versatile, and easy to use.

- Free water and operating cost analysis.

- Operates on natural gas and liquid propane gas. The system can be configured to use no. 2 oil or waste oil with optional waste oil burner.

- Easiest system on the market to clean; waste is dry ash.

- UL-508A Panel Shop Certified

- Meets stringent NFPA86 Fire Safety Code requirements.

- Will eliminate disposal cost and/or sewer discharge.

- Low operating cost.

- Low maintenance.

- Meets National Electric Code for indoor maintenance facilities

- Wetted surfaces are non-ferrous- eliminating rust and corrosion problems.

- State of the art computerized process and safety system.

Thermo-Oxidizer is designed for waste disposal applications such as:

- Petroleum hydrocarbon waste

- Die casting

- Alkaline cleaners

- Machinery coolants

- Compressor wastes

- Ink and paint waste

- Tumbling solutions

- Waste haulers

- Process wastewater

- Printed Circuit board waste

- Tank cleaning

- Floor scrubber water

- Plating solutions

- Textiles

- Heavy equipment

- Food processing

- Manufacturing processes