Vobis - Rising Film Evaporator

The Rising Film evaporator, also known as a Vertical Long Tube Evaporator, concentrates a solution by vaporizing the solvent within a column of liquid. The design is simple, reliable, and offers stable operation with minimum CAPEX investment. Our Vobis rising film evaporators are either single or multiple effect and can be combined with falling film or forced circulation stages as the solids and viscosity increase. At Vobis, we customize each evaporator design depending on the client’s required application with the goal of producing an optimal product with maximum efficiency and cost effectiveness.

Our Rising Film Evaporators are designed to handle:

- Non-salting and non-scaling feed streams

- Thermally sensitive materials

- Foaming products that require vapor separators

- Also, any scaling deposit removal is made easier by the increased feed rates.

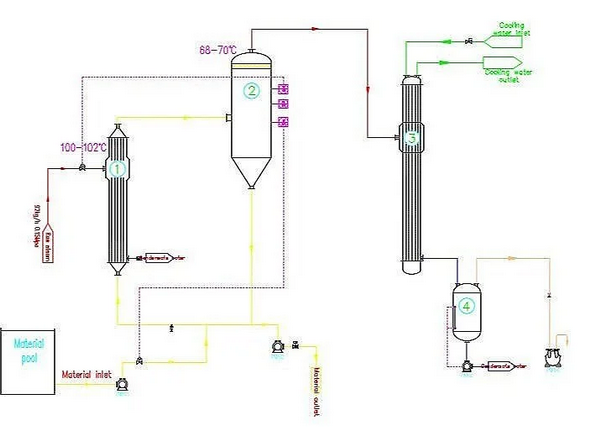

In our Rising Film Evaporators, as the liquid to be evaporated enters the tube from the bottom and is heated by steam or hot oil on the outside of the tube, the liquid inside is brought to a boil. The steam and vapor produced inside the tube by the boiling, forces the liquid against the walls and as more steam is produced the higher velocity in the center of the tube causes the liquid against the walls to ascend in a thin film.

Evaporation of the volatile components typically occurs under vacuum conditions, to minimize product heat exposure. Disentrainment of the evaporated materials takes place in a separate specially designed disentrainment vessel.

The primary advantage of the Rising Film Evaporator is the low residence time of the liquid in the evaporator which enables the use of higher operating temperatures even when dealing with a heat sensitive product.

In addition, the relatively high heat transfer coefficient in the Rising Film Evaporator reduces the size of the heat transfer area necessary, thus reducing the capital cost of the evaporator.

Customizing is easily accomplished with the components of this type of evaporator including special needs such as vapor separators for foaming products.

The option of operating the Rising Film Evaporator as a continuous process, rather than in a batch process operation, will save energy and time creating a much more efficient system.

Allen Bradley or Siemens PLC control systems are typically implemented to accurately and reproducibly control our rising film evaporation systems.

Skid mounting or modular framing where appropriate allows easy installation as well as ready access to all piping, control elements, and process vessels.

- Concentration of black liquors in pulp-and-paper mills

- Electrolytic tinning liquors

- Nitrates concentrating

- Spin-bath liquors