JONO - Model 1FMF1600A -Rotary Air Separator

Rotary air separator is one of sorting products that are developed by JONO`s independent research. By this separator, material is separated into heavy fraction and light fraction. With the reasonable structure, high separation efficiency, low noise, small vibration, free- block. It is widely applied in various waste treatment, especially in packaging waste treatment.

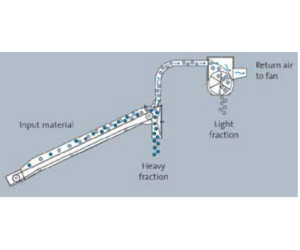

Rotary air separator system consists of circulating fan, rotary separator, air blower and connecting pipe. The separating system separates the materials with different densities and sizes in the air flow by air blower and rotary separator.

The processing is as followings.

First of all, the material goes into the rotary air separator through the internal belt conveyor.Second, the circulating fan creates a controlled flow of air that sucks relatively light materials (plastic film, foam, paper or light plastic, etc.) up and into the pipe. Heavy material (stones, metal, glass, etc) falls on the heavy material discharging belt conveyor. The light material is then transferred to the rotary separator. By the rotary separator, the light material is moved to the light material discharging belt conveyor.

- Machine size: 2682x1916x1814mm

- Input material size: 40-300mm

- Blast capacity: <36,000m³/h

- Air pressure: <5,200Pa

- Nominal voltage: 380 V

- Nominal frequency: 50 Hz

- IP Grade: IP 55

- Negative pressure (suction) separation, so that the light material from the heavy material is easily separated, to achieve high precision

- Well sealed, no dust leakage.

- The air volume can be adjusted to control the wind speed, and the angle of the air flow and speed of the feeding belt conveyor to achieve the best sep- aration effect.

- Built-in return air filter device effectively prevents floating objects from entering the pipeline to damage the fan.