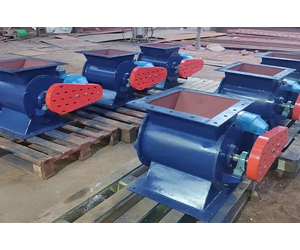

Unicon - Rotary Airlock Valve

Highlight the benefits of using rotary airlock valves, such as preventing air leakage, maintaining pressure differentials, and ensuring smooth material flow.

Reliable & Efficient Material Handling Solutions

Designed to provide a reliable and efficient solution for handling bulk materials, our valves ensure smooth and controlled flow.

- High Precision

- Durable Construction

- Easy Isolation

- Versatile Use

- Reduced MaintenanceReduced Friction

Our Rotary Airlock Valves are engineered with the latest technology to deliver optimal performance in even the most demanding environments.

- Precision Engineering

- Robust ConstructionFlexible Applications

- Easy Integration

Parameter: Data

- Application: Cement, Clinker, Gypsum, Fly Ash, Sinter dust, Sponge Iron, Coal Dust, Etc,.

- Capacity: 1 TPH to 300 TPH

- Temperature: 350° C Max

- Opening Size: Upto 1200 mm

- Flange Type: Square, Rectangle and Round

- Material of construction: Mild Steel, Stainless Steel, Cast Iron, Cast Steel, Cast Alloy, Aluminium, etc,.

- Construction: Fabricated / Casting

- Abrasion resistant lining: Sail Hard, Hardox or Stainless Steel as per requirement

- Drive type: Direct coupling and Chain Drive

Unicon Products are distributed worldwide, offering a comprehensive range of standard components, as well as international standards sanitary versions and explosion-proof models.

UNICON’s Rotary Air Lock Valves are engineered for economical and reliable material metering and airlock service, ideal for pollution control applications beneath ESPs, dust collectors, and cyclone separators. Designed for light-duty dust collection, our RAVs provide a cost-effective airlock solution.

Manufacturing Excellence:

- Materials: Available in Mild Steel (M.S), Stainless Steel (SS), Cast Iron (CI), Aluminum (AL), and Cast Alloy.

- Sizes: Up to 1200 mm.

- Flanges: Tailor-made flange types to meet your specific needs.

Key Features:

- High Filling Efficiency: Ensures optimal material flow.

- Sheared Angle Inlet: Enhances material handling.

- Minimum Air Leakage: Maintains system integrity.

- Explosion-Proof Models: Available up to 10 bar for added safety.

- Customized Solutions: Tailored to your unique requirements.

- Versatile Flanges: Square and circular options meet international standards.

- Robust Construction: Adequately stiffened body prevents distortion.

- Various Drive Options: Choose from chain, direct, pneumatic, and hydraulic drives to suit your application.

Explore how UNICON’s Rotary Air Lock Valves can enhance your operations with their superior design and functionality.