Wm. W. Meyer & Sons, Inc.

- Home

- Companies

- Wm. W. Meyer & Sons, Inc.

- Products

- Meyer - Model Klean-in-Place II - ...

Meyer - Model Klean-in-Place II -Rotary Airlock Valve

The Klean-In-Place II rotary airlock valve is specially designed for applications where frequent cleaning, sanitizing or inspection of the bulk handling system is required and minimum downtime is critical. The Klean-In-Place II has uniquely designed features making it compliant for FDA, USDA, 3A dairy and NFPA standards for materials used in food, dairy, chemical, and pharmaceutical applications. Our design incorporates a perfectly balanced 2-RAIL construction allowing the operator easy access to either clean the rotor, leaving it attached with the headplate or separating the rotor to completely remove for optimal cleaning.

Most popular related searches

rotary airlock valve

rotary airlock

airlock valve

rotary airlock feeder

bulk handling system

airlock rotary valve

rotary valve

NFPA standard

bulk handling

pneumatic conveyor

- Pressure Rating: 15 PSI

- Maximum Operating Temperature: 400°F

- Materials: Dry Free-Flowing Food Grade or Contamination Sensitive Powders

- Pneumatic Conveying, Blending, Dust Collection Drying, Weighing, Mixing, Feeding, Packaging or Bagging

- Baking Dairy, Pharmaceutical, Food, Powder Coating, Spices, Meat Processing, Chemical.

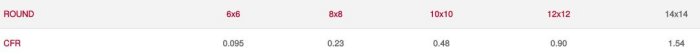

- Available in five sizes from 6×6 through 14×14

- Round flange assures system compatibility

- 316 SS housings are standard providing maximum structural stability

- Self Aligning Drive without the use of tools

- Available with packing and multiple seal designs

- Tool-Free hand fasteners for rotor removal and regular inspections

- Safety switch signaling when unit is ready to run

- Permanently sealed bearings ensure protection from contamination