- Home

- Companies

- The CMM Group

- Products

- Rotary Concentrator and Thermal ...

Rotary Concentrator and Thermal Oxidizer

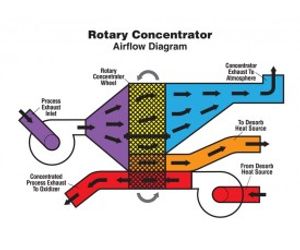

During operation, air pollutants, captured from the process via a ductwork collection system, are passed through a high-efficiency filter as particulate can damage the concentrator wheel media. Once filtered, the polluted air passes through the rotating concentrator wheel where the air pollutants are adsorbed onto the hydrophobic Zeolite media. A slipstream of this air, approximately 10%, is routed through a cooling plenum while the remainder is routed directly to the common exhaust stack.

The rotor itself is fabricated from a corrugated mineral fiber substrate to which the manufacturer permanently bonds a proprietary mixture of hydrophobic Zeolite and inorganic materials. The hydrophobic Zeolite rotor concentrator wheel is inorganic and completely inert, has rigidity, physical integrity and the ability to withstand thermal stress. In this application the Zeolite removes the air pollutant from the manufacturing process exhaust air stream as it passes through the rotor.

The concentrator wheel rotates at an approximate speed of 2-8 revolutions per hour, continuously passing a sector of the wheel with adsorbed air pollutant through a desorption plenum for removal by a heated air stream; thus continuously returning a regenerated (or clean) sector back into the main housing for further adsorption.

Desorption is automated as the slipstream of air that was routed through the cooling plenum is sent through a supplemental desorption heater were it is elevated to desorption temperature of 175 degrees C (350 degrees F) and returned to the concentrator housing. This heated desorption air is directed back through the wheel via the desorption plenum were the concentrated pollutants are removed. The highly concentrated air stream is then routed to the Regenerative Thermal Oxidizer (RTO) for thermal destruction. Overall air pollutant destruction efficiencies of 96% can typically be guaranteed.

- High air pollutant destruction efficiencies are guaranteed

- Lowest operating costs available with energy efficient design

- Designed to meet your specific project requirements

- Proven high quality components are used throughout

- Control scheme is designed to automatically react to your manufacturing process

- Modern PLC based controls with color touch-screen interface

- Data-logger is included for recordkeeping

- Meets or exceeds all regulations

Common uses include:

- Chemical processing

- FRP manufacturing

- Paint & coatings manufacturing

- Semi-conductor manufacturing

- Surface coating

- Wood finishing

- Many other applications

- 34,000 to 255,000+ NCMH (20,000 to 150,000+ SCFM)

- Suited for air streams with very low to low levels of air pollutant

Advantages:

- Low operating costs with very low air pollutant concentrations

Disadvantages:

- High capital cost

- Design limited to ~96% VOC/HAP air pollutant destruction efficiency

- Limited to low inlet temperatures

- Particulate must be filtered

- More moving parts, more maintenance