- Home

- Companies

- Zhejiang Tongli Heavy Machinery Co., ...

- Products

- Tongli - Model ZJTL Series - Rotary ...

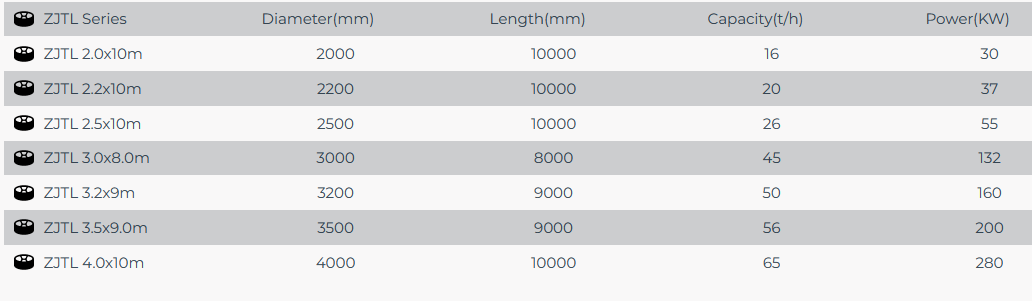

Tongli - Model ZJTL Series -Rotary Drum Granulator

The TONGLI rotary drum granulator is one of the key equipments in the npk compound fertilizer industry and is suitable for cold and hot granulation as well as the large-scale production of high, medium and low concentration compound fertilizers. The fertilizer making machine main working method is called pellet wet granulation. Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted after the humidity is adjusted in the granulator shell. Under certain liquid phase conditions, with the help of the rotation of the drum cylinder, the material particles are agglomerated to form small granule.

- NPK compound fertilizer is a type of fertilizer that contains three essential nutrients required for plant growth: nitrogen (N), phosphorus (P), and potassium (K).

- Organic fertilizer is a type of fertilizer derived from natural sources, such as plant or animal matter, minerals, or microbes.

- Organic-inorganic fertilizers, sometimes referred to as blended or compound fertilizers, are fertilizers that contain both organic and inorganic components. These fertilizers are designed to provide plants with a balanced mix of nutrients from both organic and synthetic sources.

A rotary granulator shell is a key component of a rotary granulator machine.cylindrical outer structure of the machine where the granulation process takes place. It houses the internal components responsible for granulating the materials fed into the machine. The shell is designed to withstand the mechanical stresses and operating conditions encountered during the granulation process.

- High-quality standard materials.

- ASME international certified welder.

- SGS certified third party quality inspection staff.

- Heat treating and sandblasting surface treatment.

a rotary granulator girth gear plays a vital role in transmitting torque from the pinion to the granulator drum, enabling the granulation process in various industrial applications. Its features include high strength, large diameter, precision machining, and alignment requirements to ensure efficient and reliable operation.

- TONGLI has Its own foundry, others don’t.

- TONGLI use high standard metal material.

- TONGLI use Germany spectrometer to control composition of molten metal.

- TONGLI three-phase electric arc furnace ensure casting quality.

a rotary granulator riding ring is typically made of durable materials such as cast steel or forged steel. It is designed to withstand the weight of the rotating drum and the materials being processed within the granulator.

- TONGLI has Its own foundry, others don’t.

- TONGLI use high standard metal material.

- TONGLI use Germany spectrometer to control composition of molten metal.

- TONGLI use Alkali phenolic resin sand and three-phase electric arc furnace ensure casting quality.

a rotary granulator supporting roller is a component designed to provide support and stability to the rotating parts of the granulator machine, it is mainly composed of the base frame, bearing housing, bearing, forged shaft, metal casting roller, thrust roller and position adjustment screw.

- High quality-all metal casting and welding are heat treated and Magnetic testing performed.

- All metal castings are UT ultrasonic tesed and no defect and is produced by our own.

- State-of-art design, with 65+ years of experience we have our own know-how in terms of manufacturing and design.

a rotary granulator hood cover is a protective casing that encloses the rotary granulator machine, The hood cover helps to contain the granulation process within a closed environment, preventing the dispersion of dust, particles, or vapors into the surrounding area. This containment is crucial for maintaining a clean and safe working environment, as well as for complying with regulatory standards related to air quality and occupational health and safety.

- High quality-Material.

- Advanced manufacturing process.

- Dedusting concern intergrated design.

Steam, gaseous ammonia, or phosphoric acid, nitrogen solution, phosphorus ammonia slurry, heavy calcium slurry, etc. are introduced into the drum granulator to complete the chemical reaction in the drum. Through the rotation of the drum, the material in the drum changes in humidity and The powder is agglomerated into particles under the action of temperature. Adventages of Steam-drum granulation method:

- Adapt to a variety of fertilizer formulas.

- High agglomeration rate can reach 70%.

- High drying efficiency, steam-heating.

- High quality rubber lining and SS304 Pressbar.