- Home

- Companies

- Suzhou Jono Environmental Technology ...

- Products

- JONO - Rotating Trommel Screen - Mobile ...

JONO - Rotating Trommel Screen - Mobile Mineral Ore Separator

Trommel screen is designed to effectively separate MSW, organic waste, recyclable waste, stale waste and kitchen waste by different drum screen sizes to optimize the material for the subsequent processing. JONO trommel screen can clean itself while working as it rotates,which maximize the separating efficiency and lessen the maintenance work.The high efficiency and the high quality will highly profit you in a long run time.

- After-sales Service: Instruction for Commissioning and Maintenance

- Warranty: 1 Year

- Type: disc seperator

- Object: MSW/Industrial Waste/Construction Waste..

- Drive: Electric

- Crushing Degree: mechanical sorting

- Customization: Available

Basic Info.

- Model NO.: Trommel Seperator

- Crushing Style: mechanical sorting

- Principle: material size

- Cutter Material: Hard Alloy

- Finished Surface: Cut Off Tool

- Compressive Strength (For Crushing): >300MPA

- Tongs′ Features: Adjustable Tongs

- Lead Time: 1-3 Month

- Customize: Welcome

- Color: White/Orange/Blue/Black/Customize

- Weight; 3100kg

- Transport Package: Container

- Specification: 1FDS1590A

- Trademark: Jono

- Origin; Jiangsu, China

- HS Code: 8464909000

- Production Capacity: 10/Month

Trommel is installed in a small angel with the input end a little higher than the output end.After having entered into the drum,the material moves along with the drum`s rotation.During the rotation and the moving forward,the small sized material drops through the screen holes,the big sized material will be discharged at the discharging chute at the end.This rotation can make sure the material go through enough holes to greatly optimize the separation effect.

- Quick maintenance check due to a window installed on the maintenance door .

- Minimum maintenance work due to anti-winding design.

- Efficient operation with electrical drive.

- Save space due to compact construction design.

- Optional frequency converter.

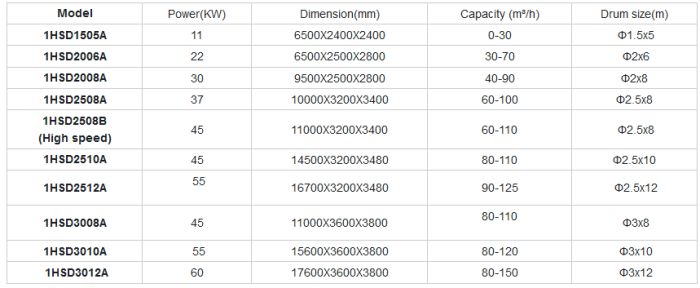

- Drum diameter size: Φ0.8-φ3m (can be customized)

- Drum length: 3-12m

- Drive unit: Gear motor 7.5-74kw

- Drum speed: 10-23r/min

- Ambient temperature: 0ºC- +45ºC

- Voltage: 3×380V±5%/50 Hz

- Control cabinet: Detached(can be integrated)

- Power control: Frequency converter

- Screen unit: Φ5-φ350mm (can be customized)

- Screening rate: 80%-95%

- Input size: ≤1000mm

- Throughput: 10-150m³/h (depending on the material and screen size)