- Home

- Companies

- Rotochopper, Inc.

- Products

- Rotochopper - Model EC-256 - Electric ...

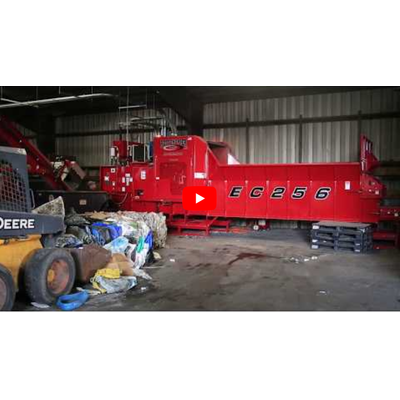

Rotochopper - Model EC-256 -Electric Horizontal Grinder

The infeed conveyor and grinding rotor on an EC-256 are 10” narrower than the EC-366, allowing it to run smoothly with less horsepower. Slightly more compact than the EC-366, the EC-256 brings the same precision grinding and consistent uptime for facilities that need “Perfect In One Pass” grinding efficiency for lower volumes of raw material.

RotoLink® Monitoring System

Monitor and adjust critical settings on your grinder with Rotochopper customer service in real-time using the RotoLink® monitoring system from anywhere in the world.

Grind & Color System

Our patented Generation II Colorizer System maximizes quality while minimizing costs by injecting colorant directly into the grinding chamber to produce mulch with the right size, texture, and color.

Screen Installation System

Our patented system allows operators to quickly change screens – reducing downtime and enhancing versatility – without needing overhead lifting equipment, fasteners or special tools.

Precision Grinding

The EC-256 brings the uptime and “Perfect In One Pass” precision necessary to convert steady streams of raw materials to premium products.

Simple Maintenance

The EC-256 maximizes uptime productivity with time-saving features like our hydraulic screen changer and StopWatch monitoring system.

Unmatched Adaptability

The EC grinder series is designed to seamlessly integrate with material handling equipment to provide complete processing solutions.

Dimensions

- Length: 30′ 9″

- Width: 7′ 8″ – 8′ 6″

- Height: 8′ 6″ – 8′ 9″

- Weight: 24,000 – 40,000 lbs.

Power Supply

- 150-400 HP electric motor

- Solid State Soft Start

- Dedicated hydraulic pump motor

*Dimensions for electric models do not include discharge conveyors

Options

- Cross-belt magnetic conveyor

- Generation II Colorizer System

- RotoLink® remote monitoring system

- Mechanical start assist

- In-line hammermill

- High-Abrasion package

- Dust hood(s)

- Mobility package

- Variable frequency drive (VFD)