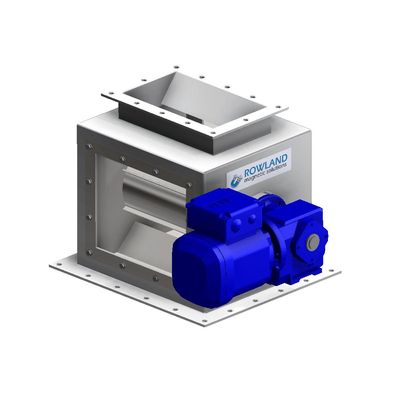

Rowland Magnetic Solutions - Model DS0404 -Drum Separator

This powerful Rare Earth magnetic Drum Separator is ideal for the removal of ferrous and paramagnetic particulates from a range of dry free flowing products, and is therefore suitable for filtration of products within the food, chemical, pharmaceutical, ceramic, animal feed, and recycling industries. The Drum Separator is a fully bespoke product and can be designed to fit any size or shape of chute, with flanges to suit each customer’s requirements. As product flows through the separator, it falls onto the drum surface. As the drum rotates, fins move the contamination to the rear of the drum where the magnetic area ends, causing the contaminant to fall through a secondary chute. The powerful Rare Earth magnets within the drum can extract ferrous particles as small as 0.5mm.

The Drum Separator is low maintenance and highly efficient as it offers continuous removal of contaminant without the need to stop the production process for cleaning.

A removable panel is included to allow access for maintenance. This can be substituted for a clear panel to provide an inspection window if required.

- Material 316L / 304L

- Size & Drum speed to suit application

- Hygienic design

- Min. Fe-particle size that can be caught 0.5 mm

- Max. operating temperature 60 °C (Higher temp designs available)

- Surface Finish Bead Blast (standard) other finishes available

- Seal FDA / Metal Detectable (Other elastomers available)

- Shaft Seal Lip seal (Single mechanical seal available)

- Pressure + / – 0.2 Bar (High pressure designs available)

- Field strength (flux density) on Drum (±5%) 3500 or 6000 gauss

- ATEX Zones Gas Zones 0, 1, 2 and Dust Zones 20, 21, 22