Royal-Arc - Round Sling

ALWAYS protect roundslings from being cut or damaged by corners, edges and protrusions using protection sufficient for each application. Do not ignore warning signs of misuse. Cut marks detected during any sling inspection serve as a clear signal that sling protection must be added or improved.

Edges do not need to be "sharp" to cause failure of the sling. Chamfering or cutting off edges is not an acceptable substitute for fully rounding the edges to the minimum radius. Slings can also be damaged from contact with edges or burrs at the sling connection.

Sling Hardware and Connections

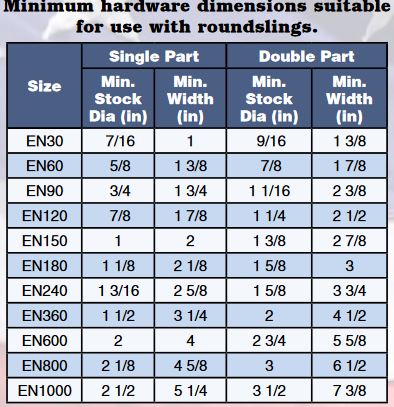

Connection surfaces must be smooth to avoid abrading or cutting roundslings. Roundslings can also be damaged or weakened by excessive compression between the sling and the connection points if the size of the attachment hardware or connection area is not large enough to avoid this damage. Select and use proper connection hardware that conforms to the size requirements listed for choker and vertical hitches, or for basket hitches in the charts below.