WZ Magnetics - Model RCND -Rubber Coated Magnets with Female Thread

Neodymium magnets are also known as super magnets. With rubber coated, the anti-scratch neodymium magnet can leave no marks and prevents surface of ferrous item from scratching. The soft rubber prevents magnets from chipping easily and corrosion for oxidation for sustained when used in outdoor environment. Strong neodymium threaded magnets with covered rubber can achieve various applications like mounting for lighting,camera,tools and equipment,etc.

Since this rubber coated magnet has an internal thread and an external thread for fixing with other accessories such as plastic clips, hooks or handles, they will have other special applications such as the cable installation, pipe fixing or light installation. And it can be also compatible for kinds of miniature hardware assembly, like the camera bracket, video,the display panel , automatic equipment, tools and machines.

Rubber Coated Neodymium Magnet Product Structure

- Neodymium magnets — Strong force

- Steel parts —- two version for choice ( regular metal and Stainless Steel )

- TPV Rubber —- can protect the surfaces from scratching and sliding, and protect the magnet inside at the same time

- Female thread —can be screwed onto a suitable component and works as a mounting base

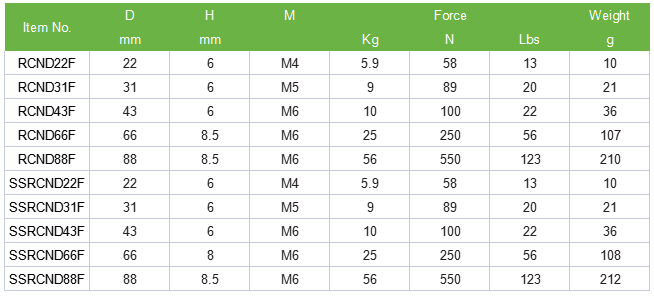

Steel plate material

The regular series is produced using ordinary metal.

Model number with “SS” means that all metal parts use stainless steel material to bring higher corrosion resistance.

The two series of products have the same dimension and force.

NdFeB magnet arrangement

To obtain the great power of the rubber-coated magnets, our engineering team designed a special internal disk magnet arrangement with alternating North (N) and South (S) poles facing upwards.

Rubber Coated Magnets With Female Thread Advantages

- Much Stronger Neodymium Rubber Coated Magnet

- No Scratch of Mounting Magnet

- Much More Compatible Neodymium Cup Magnet with different Female Thread

- Good Corrosion-Resistance of Rubber Coated Neodymium Magnet

We test the holding force of magnetic assembly by attaching it to a 20mm thick steel plate (low carbon steel with no coating) at room temperature and then pulling it slowly in vertical direction with the device that is sensitive enough to record the strength at the moment when the magnetic assembly is separated from the steel plate. This is to give you a reference while the actual holding force in real application could be different with the change of pulling direction, the thickness of the steel, surface treatment, etc.