- Home

- Companies

- Weizhong Magnetics Co., Ltd

- Products

- WZ Magnetics - Model RCND - Rubber ...

WZ Magnetics - Model RCND -Rubber Coated Magnets with Male Threaded Stud

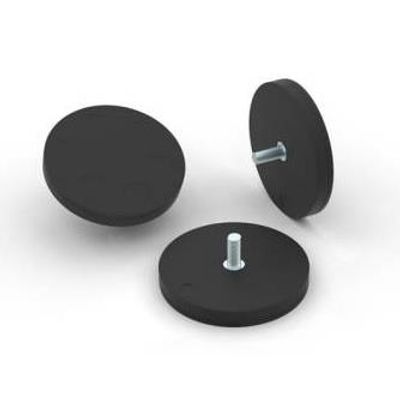

Rubber coated magnets with Male Threaded Stud is designed for magnetic holding purposes on delicate contact surface, with its rubber coating, made of TPV featuring better durability, providing protection against scratching, as well as increasing friction force in shear direction, so it is also called non slip magnet. A typical use is magnetic camera mount to install camera or smartphone on a car with a strong rubber coated neodymium magnet base to shoot video when driving. No gluing, drilling, welding, no damage to your car, just need a rubber coated magnet base.

The threaded bolt provides an easy way for mounting or installation. Which can be customized in stainless steel to have even higher corrosion resistance for application in outdoor or harsh environment. It can be connected to objects with matching inner threads or nuts, for example, to work as a magnetic mount base for cameras, beacons or emergency lighting systems etc.

Rubber coated magnets with male threaded stud in different colors

We produce black, white, red, yellow rubberized magnets. Different colours enable you to distinguish from other parts in applications like organization; Red and yellow are warning colors. Or allow you to match the same color in decoration or DIY.

For example, To use black magnetic cable holder to fix and manage black wire, white magnets for white power cord.

Rubber Coated Neodymium Magnet in various sizes

Rubber coated magnet is a product that perfectly combined magnetic force and rubber protection. To meet different requirements of industrial, commercial, civil applications.

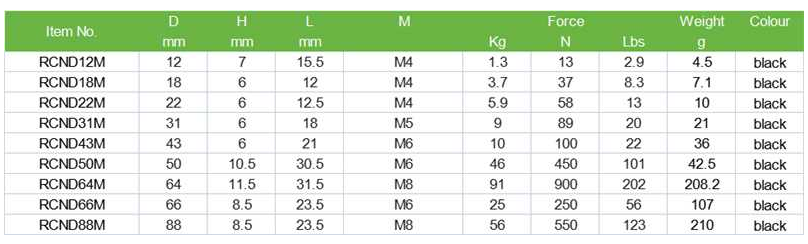

Our NdFeB rubber coated magnet with threaded stud includes 9 different diameters

Ranging from D12mm(with M4 male thread),D31mm(with 5 male thread) to as big as D66mm(with M6 male thread) and D88mm(with M8 male thread). With the Min vertical holding force of 13N and the Max vertical holding force of 550N.

We test the pull force of magnetic assembly by attaching it to a 20mm thick steel plate (low carbon steel with no coating) at room temperature and then pulling it slowly in the vertical direction with the device that is sensitive enough to record the strength at the moment when the magnetic assembly is separated from the steel plate. This is to give you a reference while the actual holding force in the real application could be different with the change of pulling direction, thickness of the steel, surface treatment, etc.