- Home

- Companies

- SSI Electronics, Inc.

- Products

- SSI - Rubber Keypads

SSI - Rubber Keypads

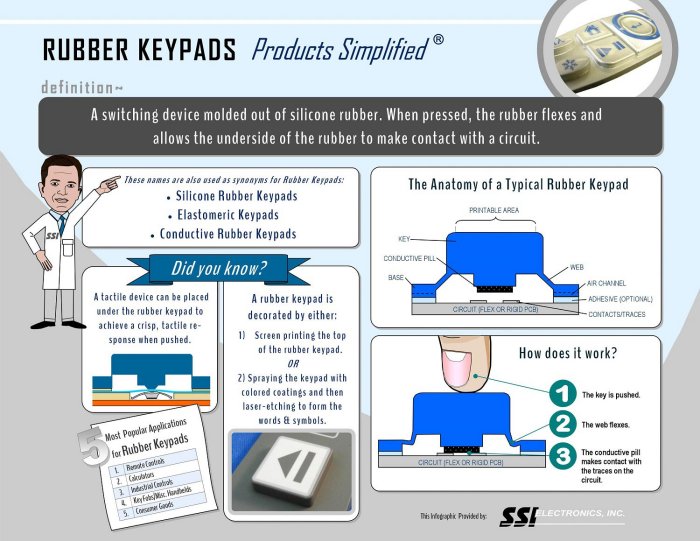

Silicone rubber keypads create an intuitive interface for a range of consumer and industrial products. The design and materials used offer durability while maintaining enough flexibility to work with a variety of product types. A broad temperature range and resistance to water and contaminants also make these high-performance keypads a solution for industries ranging from consumer goods to medical products.

For years, customers have trusted SSI Electronics’ rubber keypads as a reliable interface for consumer products like calculators and remote controls. We manufacture custom silicone rubber keypads from compression-molded elastomer that mimics the full-travel feel of a mechanical keypad. This technology’s inherent features offer many advantages over similar injection-molded keypads. Most notably, rubber keypads act as a highly effective moisture barrier to protect sensitive electronic components.

A key advantage of electronic rubber keypad technology is the ability to use pressure-sensitive adhesive to marry them with flexible printed circuits, eliminating the need for bulky mechanical fasteners. There are more opportunities than ever to employ versatile, cost-effective rubber keypads into your human-machine-interface.

Contact SSI Electronics to learn more about our high-performance rubber keypad technology or call us at 800-959-4818 with your project requirements.

Perceived Higher Value

Because a rubber keypad offers the 3-dimensional profile of a mechanical switch, it is typically perceived as a higher-end product. Unique decorative options, such as key caps and epoxy coating, can further enhance a rubber keypad’s look.

User-Friendly Interface

Due to the flexible nature of rubber and the unique shapes for which it can be molded, a superior actuation feel can be achieved with silicone rubber keypads. This is particularly true for keypad configurations requiring tight clusters of keys. “Bosses” can be molded on the rubber keypad’s underside to interface with very small metal domes to provide an exceptional tactile response.

Allows for Unique Backlighting Options

Non-tinted silicone rubber makes an excellent diffuser of light. Integrating laser etching and SMT LEDs on a circuit layer allows backlighting with a single LED.

Lower Tooling Cost Compared to Injection Molding

The compression molding process used to create SSI’s rubber keypads utilizes tooling that costs far less than the tooling used in injection molding. Typical production tool cost for a rubber keypad is between $2,000 and $5,000. Additionally, we offer prototype tooling options that often cost less than $1,500.

For those who like the look and feel of a rubber keypad but have an application requiring more design flexibility, our custom hybrid keypads could be the perfect solution. Hybrid keypads provide the same reliability, moisture and impact resistance as our rubber keypads, but with an enhanced look and feel. Our hybrid keypads also have a fully customizable tail and the ability to place your PCBA wherever you’d like.