- Home

- Companies

- Saltec International

- Products

- Saltec - Model SBT - Belt Thickener

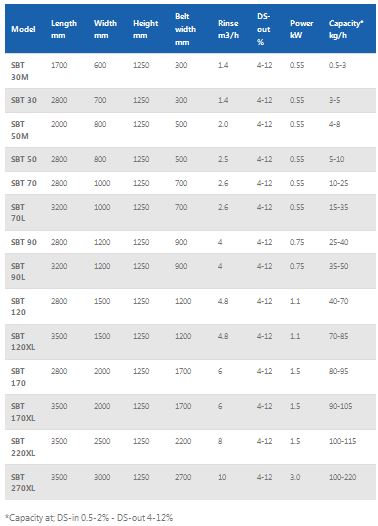

Saltec - Model SBT -Belt Thickener

SALTEC Belt Thickener separates sludge and water by gravity and static filtration. Mechanical thickening is an effective pre-dewatering stage to greatly save volumes for transport and to increase the efficiency of digestion and dewatering.

Sludge is led in through a unique polymer-injection and mixing system to ensure optimum effect without needing a flocculation reactor and then spreads out evenly on top of the SBT “gravity” zone.

The “gravity” zone of the thickener features ploughs (chicanes) that continuously turn, push, compress, and distribute the flocked sludge evenly across the width of the belt allowing optimal drainage of free water.

At the end of the belt, the sludge is pushed up and retained by an adjustable ramp to extend drainage time and provides further control of the outgoing DS-content. The belt is cleaned with a water nozzle-spray cleaning system at 5 bar to keep the belt from clogging. Filtrate can be reused as wash water.

The thickener is manufactured in stainless steel AISI 316 with fully enclosed parts and suction sockets.

- Compact, Automatic, Hygienic, CE-approved.

- Gravity table technology gives best filtrate and highest capacity.

- Included XPI poly injector and SFM mixer to ensure complete mixing without a reactor.

- Enclosed ventilated system to eliminate aerosol and odour.

- Entirely from thick stainless steel with included motor ball valve.

- Patented ramp for enhanced thickening performance.

- Specially designed adjustable ploughs with self-clearing profile.

- High capacity, performance, and reliability.

- Silent operation with low maintenance and energy consumption.

- Easy access for inspection and cleaning.

- Very gentle treatment of flocculated feed.

- Modern design and manufactured with the best materials available.