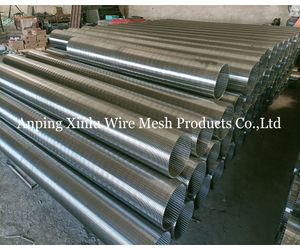

FY-XL - Model 05 No Magnetic V Wire Johnson -Sand Control Water Well Screen

Water Well Screen for Sand Control Benefits 1. Maximum Flow Rate The slots are arranged in a uniform pattern, allowing water to enter the screen directly from all directions of the water bearing area. 2. Excellent Sand Control Performance Traditional perforated tubes have holes large than 1 cm, which do not keep sand out. Scratches and corrosion on the outer wrap layers leads to more sand, gravel and clay entering the well pipe, which in turn leads to clogging. However, the wedge wire screen has slot openings between 0.5mm and 1.5mm, keeping most sand and abrasive particles out. 3. Long Well Life Each wedge wire screen undergoes anti-corrosion treatments, rendering it less prone to rust or encrustation. 4. Easy Installation Wedge wire screens are lighter than cast iron pipes or perforated tubes, making them easier to install. 5. Standard Length The standard length of each wedge wire screen is 3.2m. Pup joints can be added upon request. 6. Connection Method Welded, threaded, and

water well screen, perfect roundness screen tube, profile wire screen pipe, wedge wire screen, wire wrapped screen, screen tube, screen pipe, sand control well screen, oil well screen, v wire slot screen, rod based continuous slot screen, wire wound stainless steel screen pipe, johnson well screens

Features of wedge wire screen pipe

1. High Open Area

More than 25% of open area allows water to seep through the dewatering screen at a reduce speed, while allowing for a lower flow resistance. The enhances the water removal rate, resulting in a more efficient water removal process.

2. Non-clogging Performance

Continuous slots widen inwardly from the screen surface to minimize the chance of sand clogging the slot opening,

3. Excellent Pressure Resistance

The wedge wire screen is welded in a single from with no weld seams on the surface. Precise welding technology gives the screen its strength, making it ideal from high pressure applications

4. Great Sand Barrier

Precisely machined slots keep sand, silt and clay from entering the well, preventing abrasion.

5. Easy Installation

Compared to bridge slot screens or cement pipes, the wedge wire well screen in lightweight and easy to lay on the ground. It is also safe and convenient.

6. Material

The screen is available is galvanized, low-carbon steel, or stainless steel in grades 304 and 316, Premium materials do not retain sand and other impurities, ensuring a non-clogging performance.