- Home

- Companies

- ENVITES, spol. s r.o.

- Products

- Envites - Sand Filtration

Envites - Sand Filtration

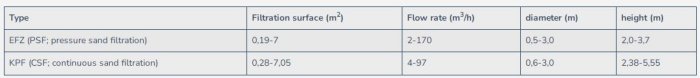

Delivery of technology for sand filtration. Sand filtration technology is one of the traditional and years-proven methods of fine water filtration. Sand filtration stands out for its high efficiency and low operating costs. It is suitable for pre-purification and post-purification of surface, river, cooling, and industrial water. Sand filtration provides the possibility of regeneration of the filter layer by washing it with water countercurrent. We produce closed pressure and open continuous sand filters.

- Low operating costs

- High filtration efficiency

- A selection from several types

The pressure sand filter is a discontinuous filter device that we produce and supply in size ranges with a diameter of 500 to 3,000 mm with a flow rate of 2 to 170 m³/h. The tank is made of steel and treated with an anti-corrosion coating (most often epoxy). On request, we can supply a stainless-steel tank. The pressure filter is equipped with fittings with manual, electric, or air drive.

The liquid is purified when it passes through the sand layer. The liquid is fed over this layer and suspended particles are separated from the liquid during the passage through the sand. The filtered liquid exits under the filter layer out of the device for further treatment. The sand is regularly washed with the water countercurrent. Due to the different sedimentation properties of sand and suspended substances, the sand is by washing effectively cleaned. Contaminated washing water is discharged from the device to the next treatment process.

- High performance

- Operational reliability

- Minimum maintenance requirements

Design and custom-made production

We will design, produce, and deliver sand filtration technology for municipal as well as industrial water treatment plants and wastewater purification plants on a turnkey basis. Our supply includes turnkey design, production, and transport of the equipment and, of course, the installation of the filter technology and its commissioning, including operator training. We also provide you with warranty and post-warranty service.

We produce a continuous countercurrent sand filter in seven size series with diameters from 600 to 3,000 mm (filtration surface from 0.28 m² to 7 m²). The construction of the shell of the tank is made of stainless steel, polypropylene, or fiberglass. The built-in segment is made of stainless steel or polypropylene.

The liquid is cleaned when it passes through the sand layer. The liquid enters through the neck in the middle part of the container into the distributor, which distributes it evenly into the filter layer. Suspended particles are separated by passing the liquid through the filter layer. The filtered liquid exits the device in the upper part of the container through the overflow edge. Contaminated sand is sucked from the bottom part of the container and is lifted through the central pipe into the washing space in the upper part of the container. Here, the sand enters the vertical countercurrent column and is washed by part of the filtered liquid stream. Due to the different sedimentation rates of suspended substances, the sand is cleaned. Contaminated washing water exits the device through an overflow above the column. By circulating the sand, the filter layer is continuously regenerated without the need to shut down the filtration process.

- Continuous operation

- Operation without an operator

- High operational reliability

- Minimum maintenance requirements

- Maintenance of performance even under an unstable load